A packaging material for beverages

A technology for packaging materials and beverages, applied in the field of biodegradable packaging materials for beverages, can solve the problems of pure starch-based plastics with low mechanical properties and heat resistance, poor plastic properties and mechanical properties, and unsuitable for beverage storage. Simple and feasible, good plastic properties and mechanical properties, and the effect of enhancing the performance of oxygen barrier and moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A packaging material for beverages, which is prepared from the following raw materials in parts by weight:

[0020] Polyhexamethylene adipate (also known as polyhexamethylene adipamide, abbreviated as NY66) 50, polyvinyl alcohol 45, polyvinylidene chloride 30, polyethylene glycol 20, polyglycolic acid 18, corn starch 12 , bamboo fiber 10, egg shell powder 8, fatty acid sodium 6, zinc oxide 5, epoxidized soybean oil 3, talc powder 1, diatomite 1; the cornstarch, egg shell powder, talcum powder and diatomite particles The average diameter is controlled above 300 mesh.

[0021] The preparation method of above-mentioned packing material, comprises the steps:

[0022] 1) take each raw material according to parts by weight;

[0023] 2) Add the raw materials into the reactor one by one. The temperature of the reactor is controlled at 70°C. Stir while adding the raw materials. After stirring evenly, let the reaction stand for 10 minutes to obtain the mixture A;

[0024] 3) T...

Embodiment 2

[0027] A packaging material for beverages, which is prepared from the following raw materials in parts by weight:

[0028] Polyhexamethylene adipate 60, polyvinyl alcohol 50, polyvinylidene chloride 35, polyethylene glycol 25, polyglycolic acid 22, corn starch 16, bamboo fiber 13, egg shell powder 10, sodium fatty acid 9, oxidation Zinc 7, epoxidized soybean oil 4, talcum powder 2, diatomite 2; the particle diameters of the corn starch, egg shell powder, talc powder and diatomite are all controlled above 300 mesh.

[0029] The preparation method of above-mentioned packaging material, this method comprises the steps:

[0030] 1) take each raw material according to parts by weight;

[0031] 2) Add the raw materials into the reactor one by one. The temperature of the reactor is controlled at 80°C. Stir while adding the raw materials. After stirring evenly, let stand for reaction for 10 minutes to obtain the mixture A;

[0032] 3) The mixture A obtained in step 2) is introduced ...

Embodiment 3

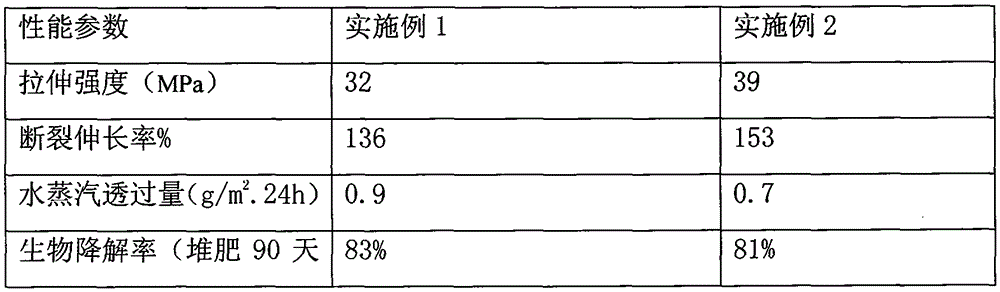

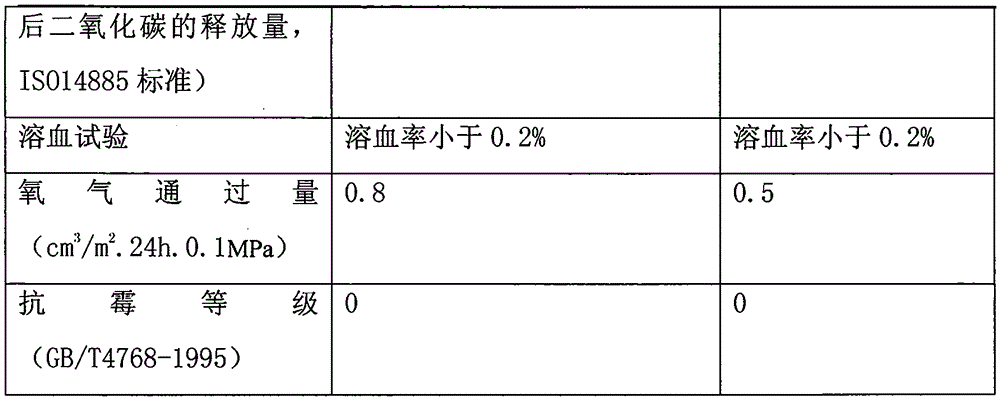

[0035] The performance test parameters of the packaging material prepared by the present invention are shown in the following table 1, and the packaging film with a thickness of 60 microns prepared in Example 1 and the packaging film with a thickness of 100 microns prepared in Example 2 are example:

[0036] Table 1

[0037]

[0038]

[0039] Conclusion: through the performance test parameters, it can be found that the mechanical properties, plastic properties and antibacterial properties of the packaging materials prepared by the present invention are better, can completely replace the existing market plastic products, and the biodegradation rate can reach more than 80%, greatly reducing the packaging cost. The material pollutes the environment and can be widely used in the field of beverage and food.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com