Filling mining method for preventing spontaneous combustion of coal bearing seam of coal mine and removing hydrogen sulfide

A mining method, hydrogen sulfide technology, applied in the direction of fire prevention, dust prevention, mining equipment, etc., can solve the problems of short stabilization time, large loss, easy flow away, etc., to achieve increased ductility, stable strength, and crack prevention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] A filling mining method for preventing spontaneous combustion of coal-bearing seams in coal mines and removing hydrogen sulfide, the specific steps are:

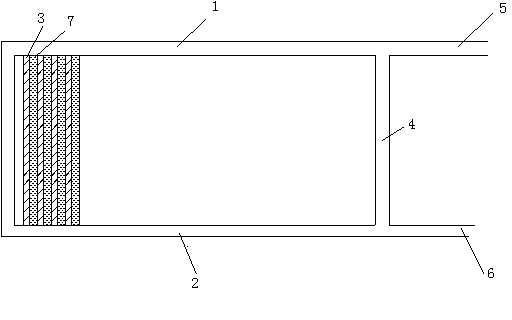

[0027] (1) Excavate the air inlet lane 2 and the air return lane 1 at a distance of 1-1.5m from the coal seam floor. The air inlet lane 2 and the air return lane 1 are arranged in parallel. One end of the two roadways is connected to the working surface, and the other One end is respectively connected to the main air inlet lane 5 and the main air return lane 6, and a connecting lane 4 is arranged at the connection between the air inlet lane 2 and the main air inlet lane 5, and the air return lane 1 and the main return air lane 6. The connecting lane 4 It is perpendicular to the air inlet lane 2 and the air return lane 1, and a damper is set in the connection lane 4 to form an air inlet and exhaust system in the mining area;

[0028] (2) According to the conditions of the mining area, design the mining width of the fil...

Embodiment 2

[0037] Example 2 is the same as Example 1, except that in the liquid foam with hydrogen sulfide removal and flame retardant functions, the hydrogen sulfide alkaline absorbent is sodium bicarbonate, potassium bicarbonate and calcium bicarbonate. Mixture, accounting for 0.5% of the total mass of the liquid foam, the inorganic salt inhibitor is a mixture of zinc chloride and sodium chloride, accounting for 20% of the total mass of the liquid foam, and the composite blowing agent is anionic-nonionic surface active Agent compound system, accounting for 35% of the total mass of the liquid foam, in which the anionic surfactant is a mixture of Φ-ester sodium sulfonate and alkyl sulfosuccinate, accounting for 60% of the mass of the composite foaming agent, non-ionic surface active agent The active agent is a mixture of polyoxyethylene alkylamine and sodium alcohol ether sulfate, which accounts for 40% of the composite blowing agent quality, and the auxiliary agent accounts for 15% o...

Embodiment 3

[0039] Example 3 is the same as Example 1, except that in the liquid foam with hydrogen sulfide removal and flame retardant functions, the hydrogen sulfide alkaline absorbent is sodium hydroxide, which accounts for 60% of the total mass of the liquid foam , the inorganic salt inhibitor is sodium carbonate, accounting for 10% of the total mass of the liquid foam, and the composite blowing agent is an anionic-nonionic surfactant compound system, accounting for 0.1% of the total mass of the liquid foam, Among them, the anionic surfactant is sodium acyl oxane sulfonate, accounting for 99.5% of the mass of the composite blowing agent, and the nonionic surfactant is a mixture of polyoxyethylene ether and ammonium lauryl polyoxyethylene ether sulfate, accounting for 99.5% of the composite blowing agent. 0.5% of the mass, the auxiliary agent accounts for 5% of the total mass of the liquid foam, specifically a foam stabilizer and a solubilizer, and the foam stabilizer is that the ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com