Ultraviolet light curing optic hardened film, preparing device thereof and preparing method thereof

A technology of ultraviolet light and hardening film, which is applied in the direction of optics, optical components, coatings, etc., can solve the problems of uneven coating thickness of optical hardening film, achieve the effects of small environmental impact, simple equipment structure, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] Utilizing the equipment provided by the present invention to prepare a UV-curable cured film, the preparation method includes the following steps: (1) adding the UV-curable coating liquid to the coating liquid coating system of the equipment;

[0060] (2) Install the transparent substrate on the machine, start the equipment and UV lamp;

[0061] (3) Set the line speed to 10 m / s and the UV light intensity to 600mJ / cm 2 ;Adjust the wrap angle between the transparent substrate and the super mirror roller to 150 degrees by adjusting the roller;

[0062] (4) Coating the coating solution through the slit extrusion die according to the designed flow rate and coating it on the transparent substrate that has passed through the dust removal system, and the thickness of the UV-cured coating solution coating is 1-15 μm;

[0063] (5) The transparent substrate with the coating solution is cured by UV embossing and then rolled up to obtain a UV cured film.

[0064] The above-mention...

Embodiment 1

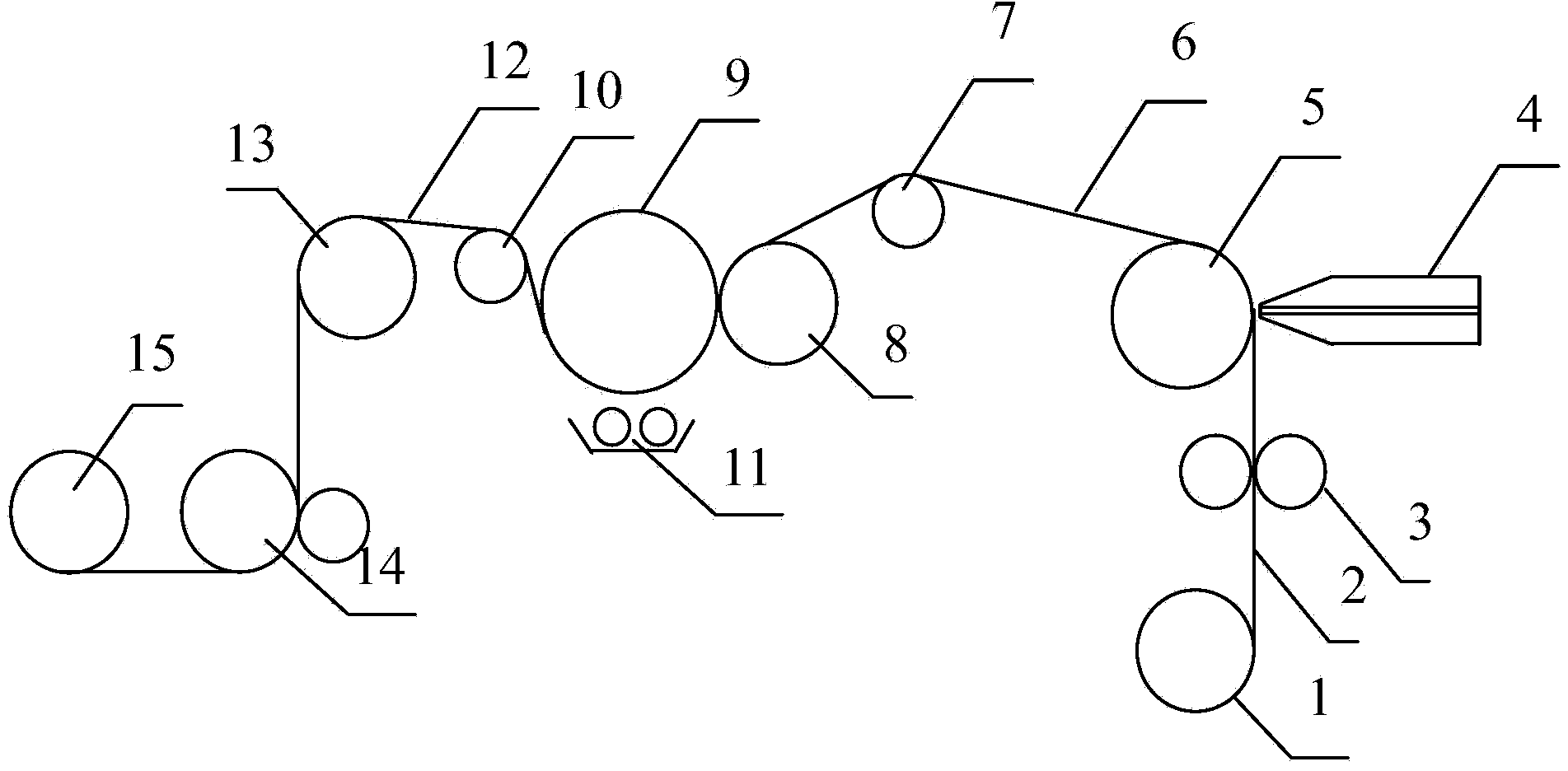

[0079] The present invention provides a kind of equipment for preparing ultraviolet light curing optical hardening film, and described equipment comprises unwinding system 1, base material surface dedusting system 3, coating fluid coating system, traction and tension control system, UV light curing press Printing system, and winding system 15; The UV photocuring embossing system consists of a super mirror roller 9, a front pressure roller 8, a regulating roller 10, a vacuum suction roller 13 and a UV lamp 11.

[0080] The diameter of the super-mirror roller 9 is 100 mm, the material is a chrome-plated roller, the surface roughness is 0.01 micron, the concentricity is equal to 5 micron, and the surface temperature difference of the roller is less than 1°C.

[0081] The diameter of the vacuum suction roller 13 is 60mm, and the minimum vacuum degree reaches 0.005Mpa. The vacuum suction roller 13 is driven by a servo motor.

[0082] The material of the front pressure roller 8 is ...

Embodiment 2

[0089] The equipment used to prepare the UV-curable optical hardening film as provided in Example 1, wherein,

[0090] The diameter of the super-mirror roller 9 is 500 millimeters, is a chrome-plated roller, and has a surface roughness of 0.006 micron.

[0091] The diameter of the vacuum suction roller 13 is 150 mm.

[0092] The material of the front pressure roller 8 is polyurethane, the diameter of the roller is less than 200 mm of the super-mirror roller, the surface roughness is less than 0.05 micron, and the Shore hardness is 90 degrees.

[0093] The regulating roller 10 is a metal chrome-plated roller with a diameter of 120 mm, a surface roughness of less than 0.05 microns, and a concentricity of less than 5 microns.

[0094] The light intensity of the electrodeless UV lamp system is 600mJ / cm 2 .

[0095] The material of the back roller 5 is a steel roller plated with nickel, and the surface roughness of the coating is less than 0.01 micron.

[0096] The surface dedu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com