Electrospun fiber-reinforced calcium phosphate bone cement composite material and application thereof

A technology of calcium phosphate bone cement and electrospinning fiber, applied in medical science, prosthesis and other directions, can solve the problems of complex preparation process and insufficient compressive strength, achieve simple and controllable preparation process, improve bonding strength, and improve compressive strength performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

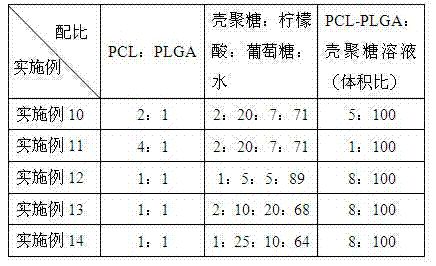

Embodiment 1

[0055] S1. Prepare polycaprolactone (PCL) and poly(lactic acid-glycolic acid) copolymer (PLGA) solutions with a mass volume ratio of 8% respectively, and mix them in a ratio of PCL: PLGA mass ratio = 1: 1 to prepare PCL- PLGA mixture;

[0056] S2. Mix chitosan by mass ratio: citric acid: glucose: distilled water=2: 20: 7: 71, stir and dissolve to obtain a chitosan solution;

[0057] S3. Put the PCL-PLGA mixture prepared in step S1. into a syringe barrel, and connect it to the positive pole of the high-voltage power supply of the electrospinning machine. Connect the chitosan solution prepared in step S2. to the negative electrode of the high-voltage power supply as a receiving device for the spinning solution. The electrospinning voltage is 15kV, the electrospinning polymer solution flow rate is 0.6ml / h, the distance between the spinneret and the chitosan solution liquid level is 12cm, and the PCL-PLGA fiber is directly spun into the chitosan solution of step S2, Obtain fiber...

Embodiment 2

[0065] The formula and preparation method in Example 1 were followed, except that 1% to 10% (wt%) polylactic acid was added to the electrospun fibers, and then a composite bone cement slurry was prepared at a solid-to-liquid ratio of 0.5g: 1ml. The prepared bone cement composite material can be directly injected into the bone defect site. The polylactic acid may be any one of racemic polylactic acid, L-polylactic acid or D-polylactic acid.

Embodiment 3

[0067] The formula and preparation method in Example 1 were followed, except that 5% to 20% (wt%) collagen was added to the electrospun fibers, and then a composite bone cement slurry was prepared at a solid-to-liquid ratio of 0.5g: 1ml. The prepared bone cement composite material can be directly injected into the bone defect site.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com