Jade porcelain and making method thereof

A production method and technology of gold and jade, applied to clay products, other household utensils, household utensils, etc., can solve the problems of high production cost, high dissolution rate, low thermal insulation performance, etc., and reduce firing temperature and raw material cost , Reduce production costs, good thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1, a kind of gold and jade porcelain, the raw material composition of its blank according to parts by weight: 25 parts of albite, 15 parts of quartz, 45 parts of kaolin, 7 parts of barium carbonate, 2 parts of sodium tripolyphosphate, 3 parts of yttrium oxide The raw materials of the glaze are composed of 70 parts of frit glaze, 7 parts of potassium feldspar and 13 parts of kaolin according to the weight parts.

[0013] Among them, the chemical composition of albite is: 19.47% alumina, 69.28% silica, 0.09% iron oxide, 0.05% titanium oxide, 0.7% calcium oxide, 0.52% magnesium oxide, 0.5% potassium oxide, 8.47% sodium oxide , 0.92% margin. The chemical composition of kaolin is: 35.96% alumina, 47.95% silica, 0.22% iron oxide, 0.01% titanium oxide, 0.45% calcium oxide, 0.57% magnesium oxide, 2.17% potassium oxide, 0.2% sodium oxide, 12.47% quantity. The chemical composition of potassium feldspar is: 10.18% alumina, 80.45% silica, 0.03% iron oxide, 0.03% titani...

Embodiment 2

[0015] Embodiment 2, a kind of gold and jade porcelain, the raw material composition of its blank according to parts by weight: 35 parts of albite, 15 parts of quartz, 60 parts of kaolin, 10 parts of barium carbonate, 2 parts of sodium tripolyphosphate, 2 parts of yttrium oxide The raw materials of the glaze are composed of 80 parts of frit glaze, 5 parts of potassium feldspar and 15 parts of kaolin according to the weight parts.

[0016] A method of making gold and jade porcelain: make the blank into a green body, then apply the glaze on the green body, dry it and send it to a kiln for firing. The firing process is as follows: from room temperature to 790°C, it takes 2 hours Continue to heat up to 1250°C for 2 hours; continue to heat up to 1280°C for 3 hours; continue to heat up to 1380°C for 2 hours.

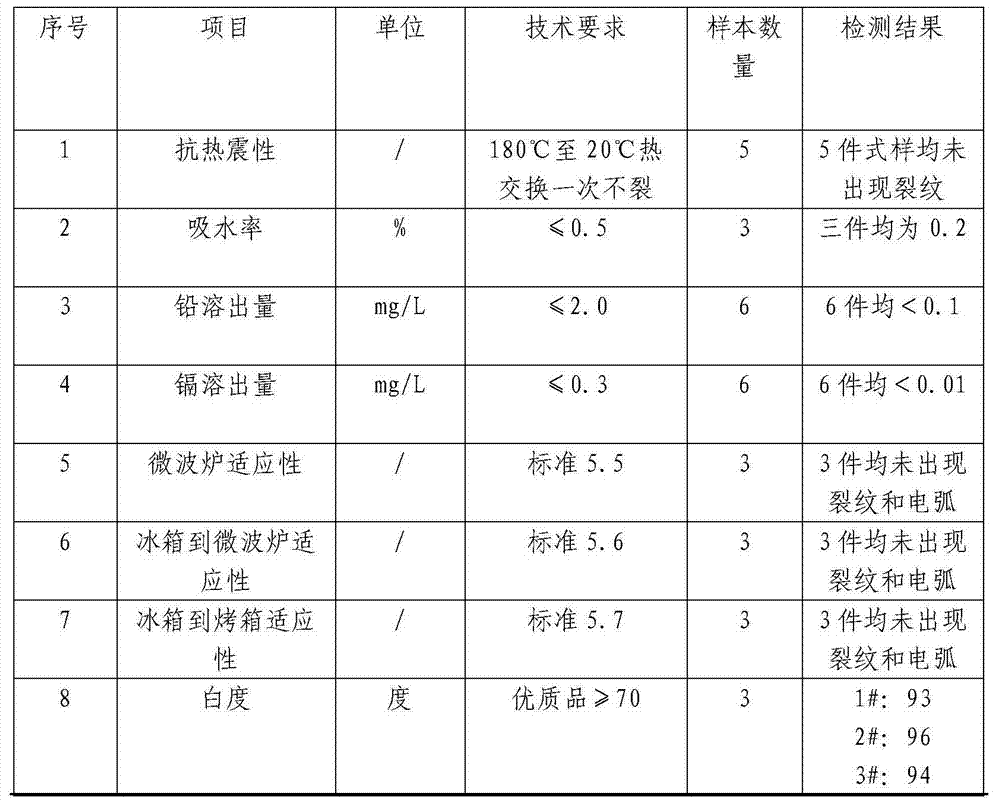

[0017] The prepared gold and jade porcelain was tested by the Fujian Provincial Daily Ceramics Product Quality Supervision and Inspection Center, and the test report is as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com