Method and device for coal chemical sewage reuse and zero emission

A technology of coal chemical industry and zero discharge, which is applied in the field of coal chemical wastewater reuse and zero discharge, can solve the problem that drainage cannot meet national or local discharge standards, achieve improved biochemical treatment effects, simple process steps, and reduce refractory pollutants Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

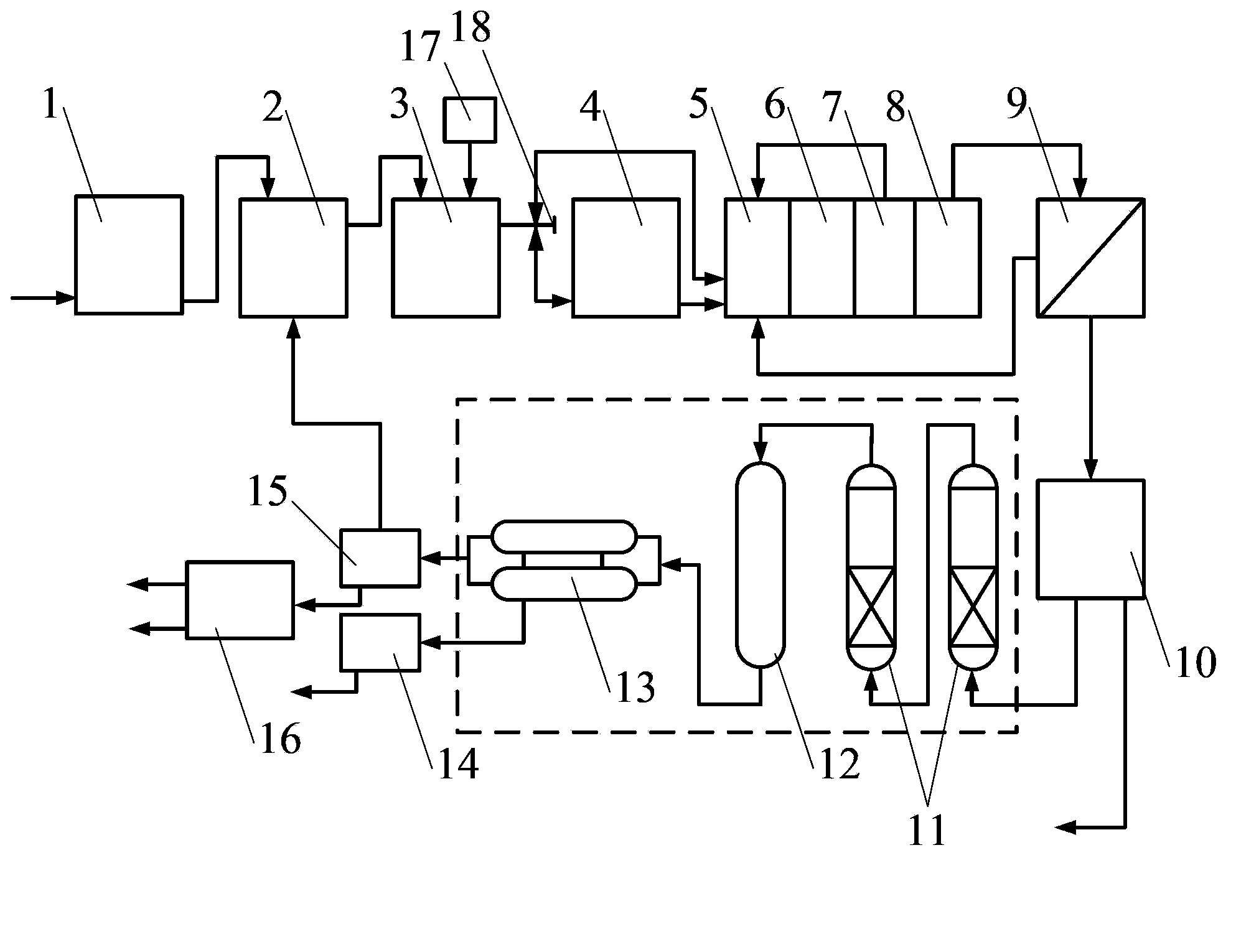

[0107] Methanol waste water from coal, raw water COD Cr It is 1000mg / L~1500mg / L, and it is treated by the method and device of coal chemical wastewater reuse and zero discharge. The advanced oxidation treatment process section is not used, and the sludge concentration of the multi-stage A / O system is 3500mg / L~4000mg / L , the system residence time is 20 hours, and the sludge reflux ratio is 100%. Membrane filtration system 9 produced water COD Cr ≤50mg / L, super efficient reverse osmosis system produced water COD Cr ≤10mg / L. Membrane filtration system 9 produces water that is colorless, clear, and odorless, and can be used in production that does not require high water quality; the water produced by the ultra-efficient reverse osmosis system has high water quality and can be used as circulating cooling water or boiler feed water; ultra-efficient reverse osmosis The concentrated water in the system is clear, colorless, odorless, and has a relatively small amount of water. It ca...

Embodiment 2

[0109] A certain coal gasification wastewater, raw water COD Cr 2000mg / L~2500mg / L, NH 3 -N is 300mg / L~350mg / L, treated by coal chemical wastewater reuse and zero discharge methods and devices, in which no advanced oxidation process section is used, and the sludge concentration of multi-stage A / O system is 3000mg / L~3500mg / L, the system residence time is 24 hours, and the sludge reflux ratio is 100%. Membrane filtration system 9 produced water COD Cr ≤60mg / L, NH 3 -N≤5mg / L, super efficient reverse osmosis system produced water COD Cr ≤10mg / L, NH 3 -N≤0.5mg / L. Membrane filtration system 9 produces water that is colorless, clear, and odorless, and can be used in production that does not require high water quality; the water produced by the ultra-efficient reverse osmosis system has high water quality and can be used as circulating cooling water or boiler feed water; ultra-efficient reverse osmosis The concentrated water in the system is clear, colorless, odorless, and has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com