Iron removing purification method for silicon carbide cutting edge material

A purification method and cutting edge technology, applied in the direction of silicon carbide, carbide, etc., can solve the problems of extended production cycle, high production cost, and low production efficiency, and achieve the effects of stable production process, shortened production cycle, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

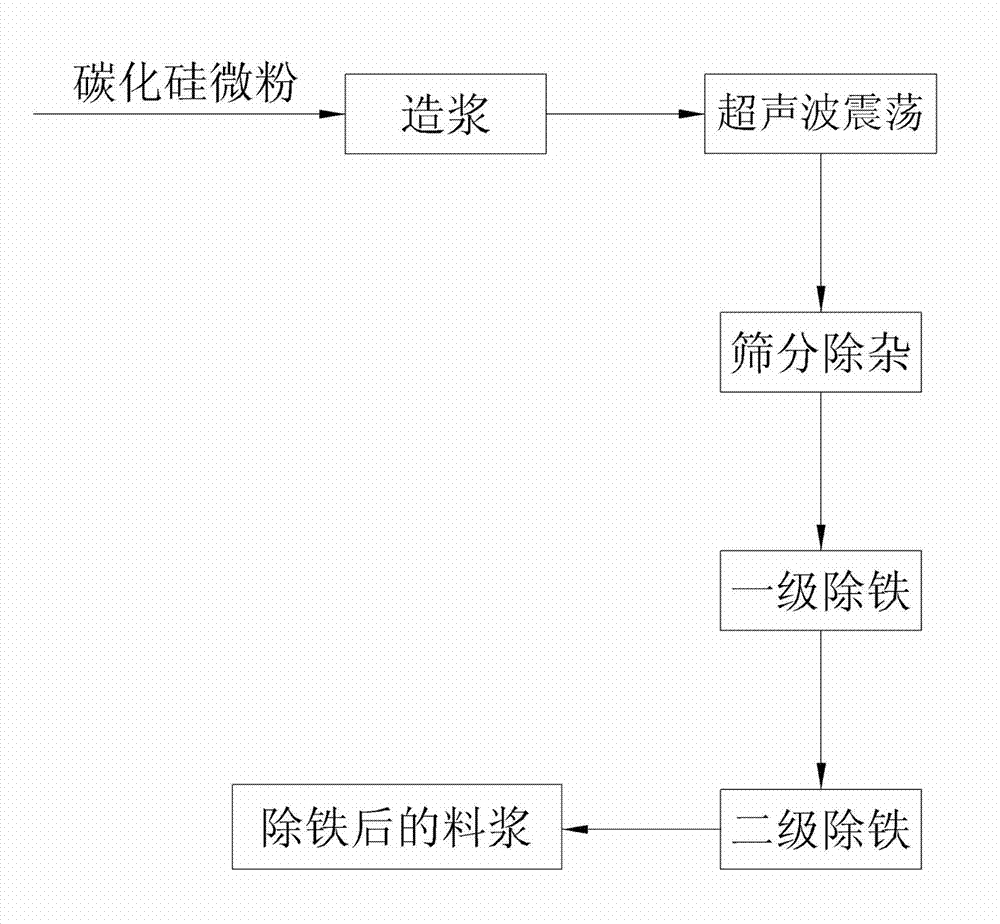

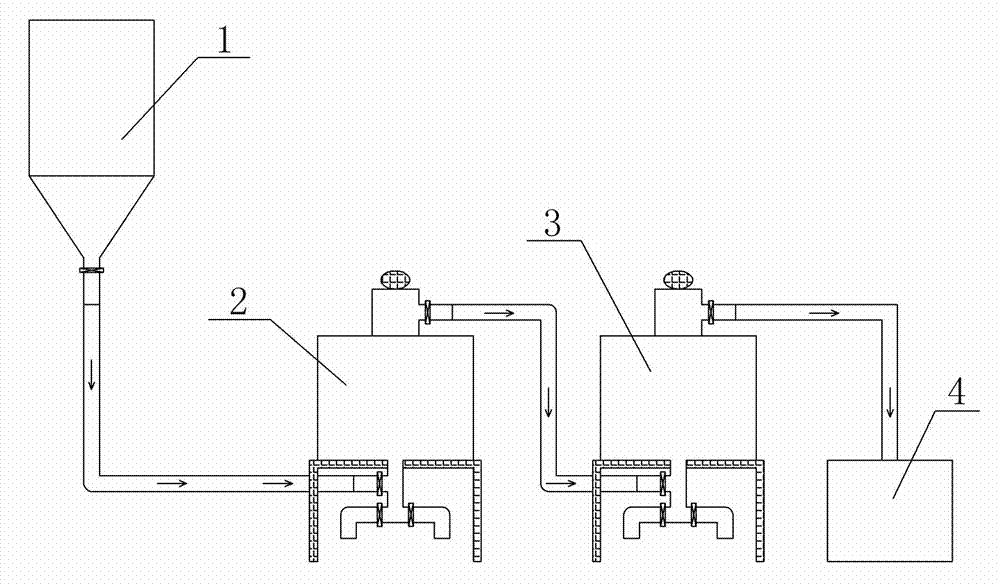

[0033] Example 1: Dilute silicon carbide micropowder with a particle size range of 14.00 μm to 4.80 μm after being pulverized by a Raymond mill and water at a concentration of 40% to make slurry, first add water and then feed, and stir for 30 minutes to make the powder Fully mix with water and make 1 ton of pulp in one slurry tank. Then the obtained silicon carbide powder slurry was subjected to vibration treatment for 20 minutes under ultrasonic waves with a frequency of 60 KHz. Then pump the slurry treated by ultrasonic vibration into the feed distributor of the water-type rotary vibrating screen, and remove impurities such as fibers, flocs, hairs, graphite particles, and large silicon carbide powders in the slurry by screening. , where the sieve screen is 363 mesh, and the impurities on the screen are cleaned every 10 hours. Collect the silicon carbide powder slurry after screening and removing impurities into the slurry tank whose vertical position is higher than the inle...

Embodiment 2

[0035] Embodiment 2: adopt the same method as embodiment 1 to carry out iron removal and purification of silicon carbide cutting edge, the difference is that the slurrying concentration is 35%, and the stirring time is 25 minutes; the ultrasonic vibration treatment adopts 50KHz ultrasonic vibration treatment for 30 minute.

Embodiment 3

[0036]Embodiment 3: Carry out iron removal and purification of silicon carbide cutting edge by the same method as in Example 1, the difference is that the ultrasonic vibration treatment adopts 30KHz ultrasonic vibration treatment for 20 minutes; the rotary vibration sieve used is an ultrasonic rotary vibration sieve. During the screening process, ultrasonic vibration is superimposed with low-frequency rotary vibration to realize the effective combination of ultrasonic vibration and vibrating screen, which can make the materials in the slurry more dispersed, further accelerate the separation of agglomerates, and prevent mesh clogging, realizing Better screening effect.

[0037] Unless otherwise specified, the instruments and equipment involved in the above examples are conventional instruments and equipment; the involved industrial raw materials are commercially available conventional industrial raw materials unless otherwise specified.

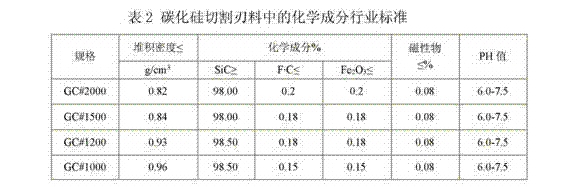

[0038] The iron removal efficiency of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com