4H-SiC metal semiconductor field-effect transistor

A field-effect transistor and metal-semiconductor technology, applied in the field of field-effect transistors, can solve problems such as lattice damage, limited improvement range, and decrease in effective carrier mobility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

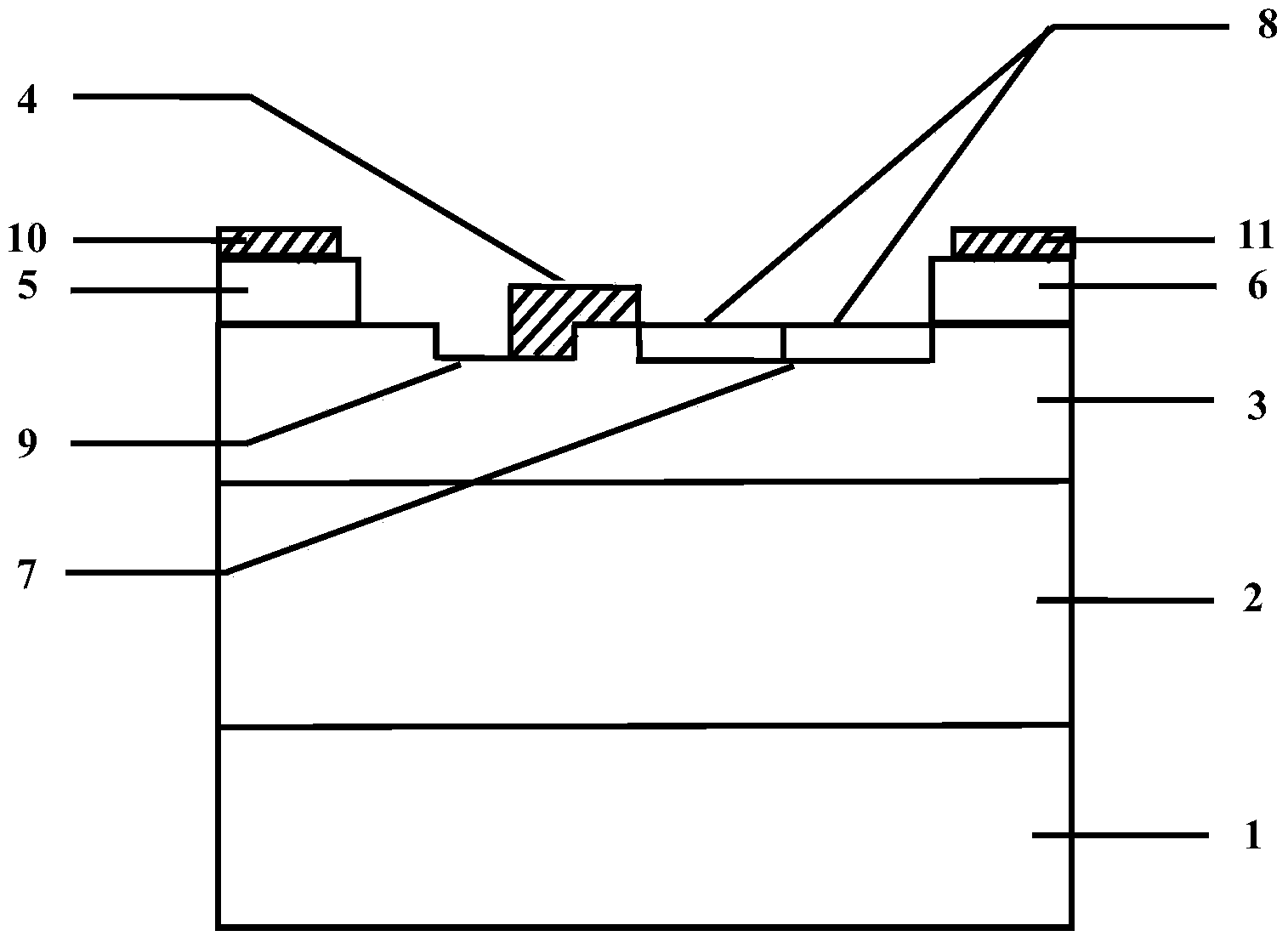

[0036] Example 1: Fabrication of a 4H-SiC metal semiconductor field effect transistor containing a PN junction with a thickness of 0.04 μm and a P region length of 0.45 μm.

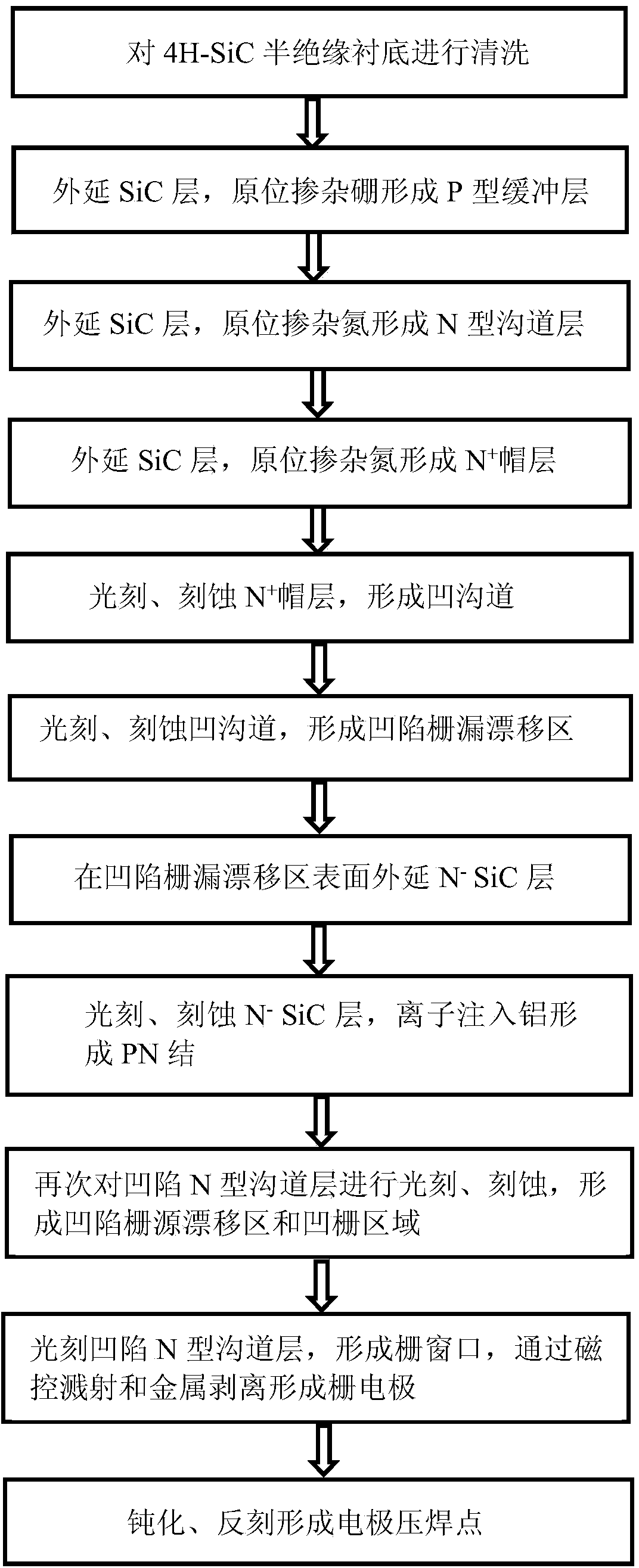

[0037] The manufacturing steps of this embodiment are as follows:

[0038] Step 1: Clean the 4H-SiC semi-insulating substrate to clean the surface.

[0039] (1.1) Carefully clean the substrate twice with a cotton ball dipped in methanol;

[0040] (1.2) Wash the substrate in xylene at 80°C, boiled acetone and methanol at 80°C for 4 minutes, and then dry it with dry high-purity nitrogen;

[0041] (1.3) Put the substrate in H 2 SO 4 With H 2 O 2 After immersing in the mixture with a ratio of 1:1 for 10 minutes, rinse with deionized water twice, and finally dry the substrate with nitrogen.

[0042] Step 2: Epitaxially grow a SiC layer on the surface of the 4H-SiC semi-insulating substrate, and form a P-type buffer layer by boron in-situ doping.

[0043] Put the 4H-SiC semi-insulating substrate into the growth chamber, an...

Embodiment 2

[0076] Example 2: Fabrication of a 4H-SiC metal semiconductor field effect transistor containing a PN junction with a thickness of 0.05 μm and a P region length of 0.5 μm.

[0077] The manufacturing steps of this embodiment are as follows:

[0078] Step 1: Same as Step 1 of Example 1.

[0079] Step 2: Same as Step 2 of Example 1.

[0080] Step 3: Same as Step 3 of Example 1.

[0081] Step 4: Same as Step 4 of Example 1.

[0082] Step 5: Same as Step 5 of Example 1.

[0083] Step 6: Same as Step 6 of Example 1.

[0084] Step 7: Same as Step 7 of Example 1.

[0085] Step 8: Same as Step 8 of Example 1.

[0086] Step 9: Epitaxy N on the surface of the recessed gate-drain drift region ‐ SiC layer.

[0087] In the growth chamber, flow of 20ml / min of silane, 10ml / min of propane, 80l / min of high-purity hydrogen and 2ml / min of high-purity nitrogen were simultaneously introduced. The growth temperature was 1550℃ and the pressure was 10 5 Continue for 36s under Pa conditions and grow 0.05μm thick N ‐...

Embodiment 3

[0094] Example 3: Fabrication of a 4H-SiC metal semiconductor field effect transistor containing a PN junction with a thickness of 0.045 μm and a P region length of 0.48 μm.

[0095] The manufacturing steps of this embodiment are as follows:

[0096] Step A: Same as Step 1 of Example 1.

[0097] Step B: Same as Step 2 of Example 1.

[0098] Step C: Same as Step 3 of Example 1.

[0099] Step D: Same as Step 4 of Example 1.

[0100] Step E: Same as Step 5 of Example 1.

[0101] Step F: Same as Step 6 of Example 1.

[0102] Step G: Same as Step 7 of Example 1.

[0103] Step H: Same as Step 8 of Example 1.

[0104] Step I: Epitaxy N on the surface of the recessed gate-drain drift region ‐ SiC layer.

[0105] In the growth chamber, flow of 20ml / min of silane, 10ml / min of propane, 80l / min of high-purity hydrogen and 2ml / min of high-purity nitrogen were simultaneously introduced. The growth temperature was 1550℃ and the pressure was 10 5 Continue for 33s under Pa conditions, grow 0.045μm thick N ‐...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com