Method for preparing aurones compound

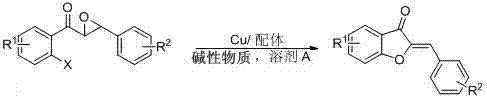

A technology for compound and orange ketone, which is applied in the field of preparation of orange ketone compounds, can solve the problems of large amount of catalyst, harsh preparation conditions, serious environmental pollution, etc., and achieves the effects of low equipment requirements, simple operation and improved economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Preparation of (Z)-2-phenylmethylene-3(2H)-benzofuranone

[0030] Add (2-bromophenyl)(3-phenyl-2-epoxy)ketone (1.52 g, 5.0 mmol) into a two-necked flask, dissolve it completely with DMF (25 ml), then add cesium carbonate (2.44 g, 7.5 mmol), CuI (0.10 g, 0.5 mmol), 1,10-phenanthroline.Monohydrate (0.2 g, 1.0 mmol), heated at 105°C under nitrogen protection, TLC monitored the end of the reaction, and the reaction was complete in about 4.5 hours . After the reaction was complete, cool down to room temperature, add 50 ml of water and 50 ml of ethyl acetate to it, separate the layers, extract the water layer with 20 ml of ethyl acetate, combine the ethyl acetate layer; wash the ethyl acetate layer with water, wash with saturated NaHCO3, Washed with saturated brine, dried over anhydrous sodium sulfate; spin-dried, concentrated, and separated by column chromatography to obtain the product orange (Z)-2-phenylmethylene-3(2H)-benzofuranone, light yellow powder 0.98g,...

Embodiment 2

[0033] Example 2: Preparation of (Z)-2-phenylmethylene-3(2H)-benzofuranone

[0034] Dissolve (2-bromophenyl)(3-phenyl-2-epoxy)ketone (1.52 g, 5.0 mmol) in a two-necked flask with toluene (25 ml), add cesium carbonate (2.44 g, 7.5 mmol ), CuI (0.10 g, 0.5 mmol), 1,10-phenanthroline (0.18 g, 1.0 mmol), nitrogen protection, 105 ℃ heating TLC to monitor the end of the reaction, the reaction was complete in about 4.5 hours. After the reaction was complete, cool down to room temperature, add 50 ml of water and 50 ml of ethyl acetate to it, separate the layers, extract the water layer with 20 ml of ethyl acetate, combine the ethyl acetate layer; wash the ethyl acetate layer with water, wash with saturated NaHCO3, Washed with saturated brine, dried over anhydrous sodium sulfate; spin-dried, concentrated, and separated by column chromatography to obtain the product orange (Z)-2-phenylmethylene-3(2H)-benzofuranone, light yellow powder , 0.935 g, 84%.

Embodiment 3

[0035] Example 3: Preparation of (Z)-2-phenylmethylene-3(2H)-benzofuranone

[0036] Dissolve (2-bromophenyl)(3-phenyl-2-epoxy)ketone (1.52 g, 5.0 mmol) in a two-necked flask with DMF (25 ml), add cesium carbonate (0.82 g, 2.5 mmol ), CuI (0.01 g, 0.05 mmol), 2,2-bipyridine (0.015 g, 0.1 mmol). Nitrogen protection, 105 ° C heating TLC to monitor the end of the reaction, the reaction was complete in about 4.5 hours. After the reaction was complete, the temperature was lowered to room temperature, and 50 ml of water and 50 ml of ethyl acetate were added thereto. Separate the layers, extract the aqueous layer with 20 ml of ethyl acetate, combine the ethyl acetate layers; wash the ethyl acetate layer with water, wash with saturated NaHCO3, wash with saturated brine, and dry over anhydrous sodium sulfate; spin dry, concentrate, and separate by column chromatography The product arurone (Z)-2-phenylmethylene-3(2H)-benzofuranone was obtained as light yellow powder, 0.72g, 65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com