Preparation method of polysulfone cation-exchange membrane

An ion exchange membrane, polysulfone technology, applied in the field of sulfonated polysulfone, can solve problems such as being unsuitable for fuel cell applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1:

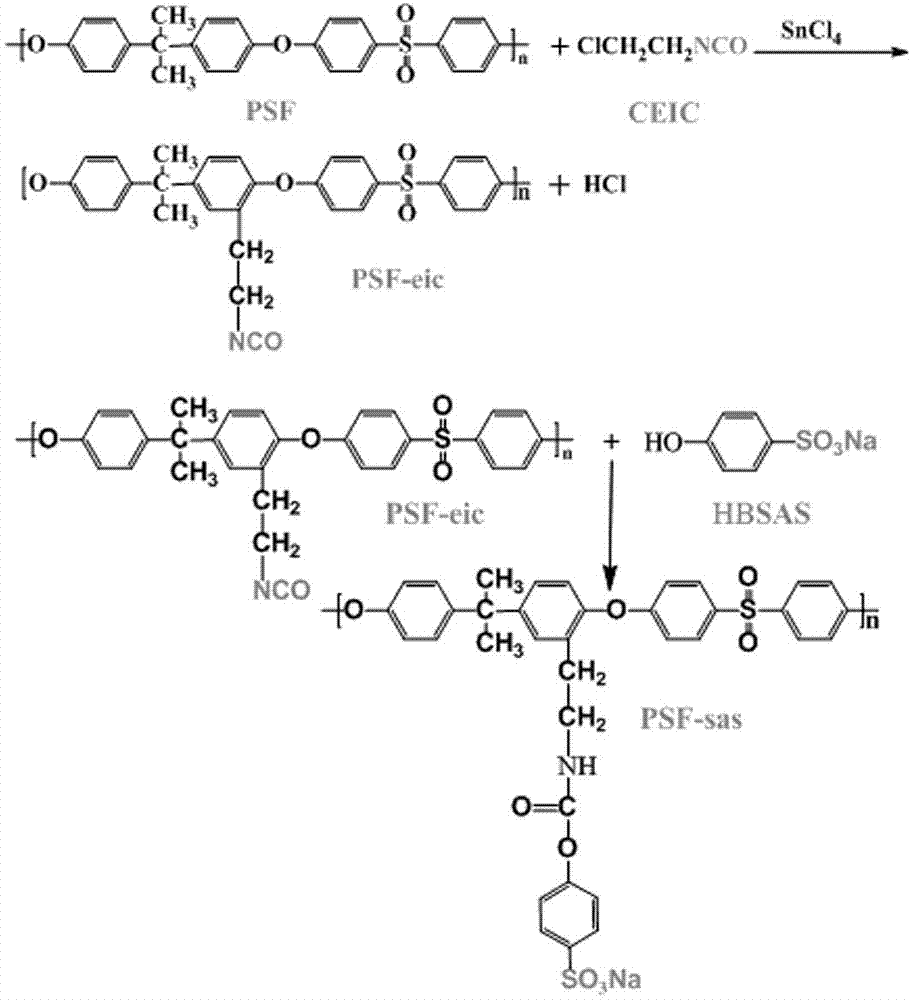

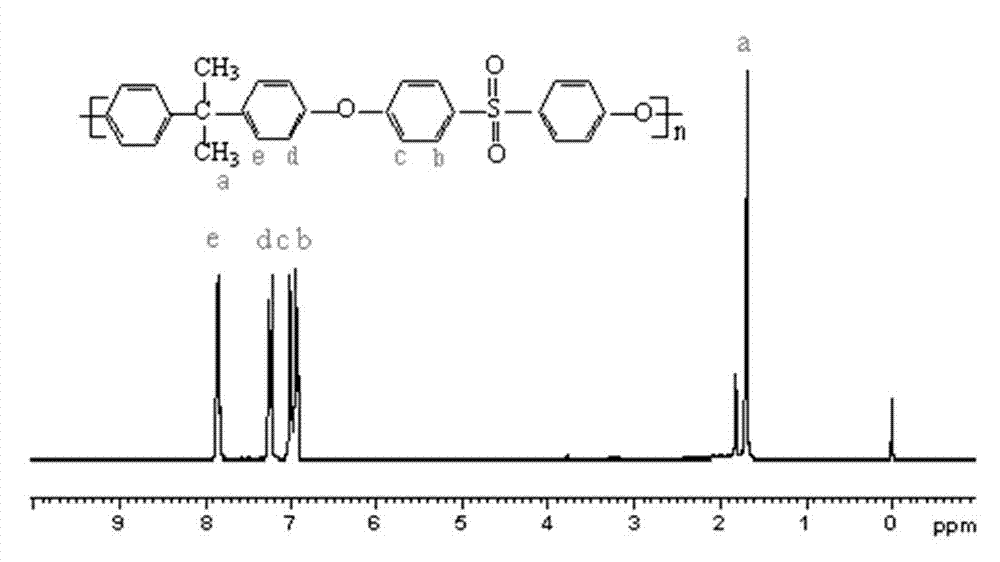

[0045] (1) Bonding of ethyl isocyanate on the main chain of polysulfone skeleton: In a four-neck flask equipped with a stirrer and a thermometer, add 0.65g of polysulfone and 48mL of N,N-dimethylacetamide to make PSF Dissolve completely; then, under nitrogen protection, add 1.3 mL of chloroethyl isocyanate and 1.3 mL of anhydrous SnCl 4 , The Friedel-Crafts alkylation reaction between chloroethyl isocyanate and PSF macromolecular chains was carried out at 60°C for 24h, and a clear and transparent intermediate product solution was obtained.

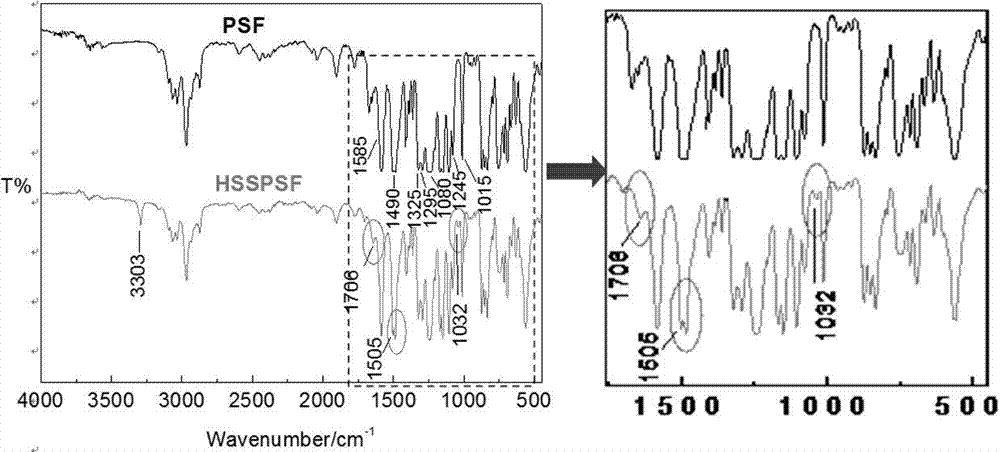

[0046] (2) Preparation of sulfonated modified polysulfone: raise the temperature of the intermediate product solution to 100°C, add 5.00g of sodium p-hydroxybenzenesulfonate and 0.04g of dibutyltin dilaurate (catalyst), to make the PSF-eic chain The reaction of the isocyanate group on the above and the hydroxyl group of sodium p-hydroxybenzenesulfonate to form carbamate was carried out for 10 hours. After the reactio...

Embodiment 2

[0051] (1) Bonding of ethyl isocyanate on the main chain of polysulfone skeleton: In a four-neck flask equipped with a stirrer and a thermometer, add 0.66g of polysulfone and 49mL of N,N-dimethylacetamide to make PSF Dissolve completely; then, under nitrogen protection, add 1.35 mL of chloroethyl isocyanate and 1.35 mL of anhydrous SnCl 4 , The Friedel-Crafts alkylation reaction between chloroethyl isocyanate and PSF macromolecular chains was carried out at 65°C for 22h, and a clear and transparent intermediate product solution was obtained.

[0052] (2) Preparation of sulfonated modified polysulfone: raise the temperature of the intermediate product solution to 100°C, add 5.20g of sodium p-hydroxybenzenesulfonate and 0.05g of dibutyltin dilaurate (catalyst), to make the PSF-eic chain The reaction of the isocyanate group on the above and the hydroxyl group of sodium p-hydroxybenzenesulfonate to form carbamate was carried out for 12 hours. After the reaction, 200 mL of ethanol ...

Embodiment 3

[0056] (1) Bonding of ethyl isocyanate on the main chain of polysulfone skeleton: In a four-neck flask equipped with a stirrer and a thermometer, add 0.68g of polysulfone and 50mL of N,N-dimethylacetamide to make PSF Dissolve completely; then under nitrogen protection, add 1.38mL of chloroethyl isocyanate and 1.35mL of anhydrous SnCl 4 , The Friedel-Crafts alkylation reaction between chloroethyl isocyanate and PSF macromolecular chains was carried out at 70°C for 24h, and a clear and transparent intermediate product solution was obtained.

[0057] (2) Preparation of sulfonated modified polysulfone: raise the temperature of the intermediate product solution to 100°C, add 5.30g of sodium p-hydroxybenzenesulfonate and 0.04g of dibutyltin dilaurate (catalyst), to make the PSF-eic chain The reaction of the isocyanate group on the above and the hydroxyl group of sodium p-hydroxybenzenesulfonate to form carbamate was carried out for 13 hours. After the reaction, 200 mL of ethanol was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com