Polyester-phenolic aldehyde-epoxy composite material and preparation method thereof

A composite material and polyester technology, applied in the field of layered materials and their preparation, can solve problems such as easy cracking and poor toughness, and achieve the effect of overcoming poor toughness and high low temperature brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

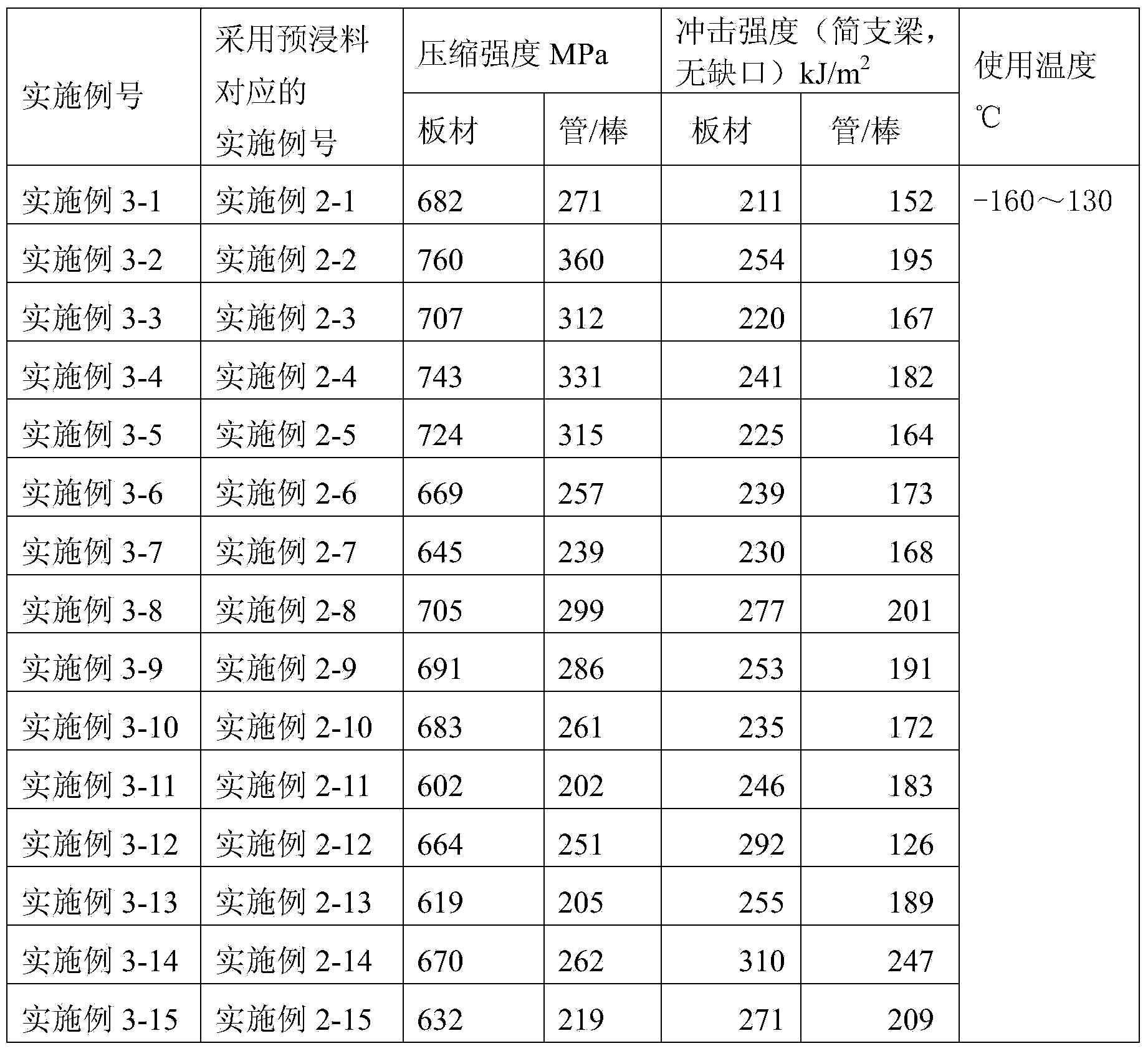

Examples

preparation example Construction

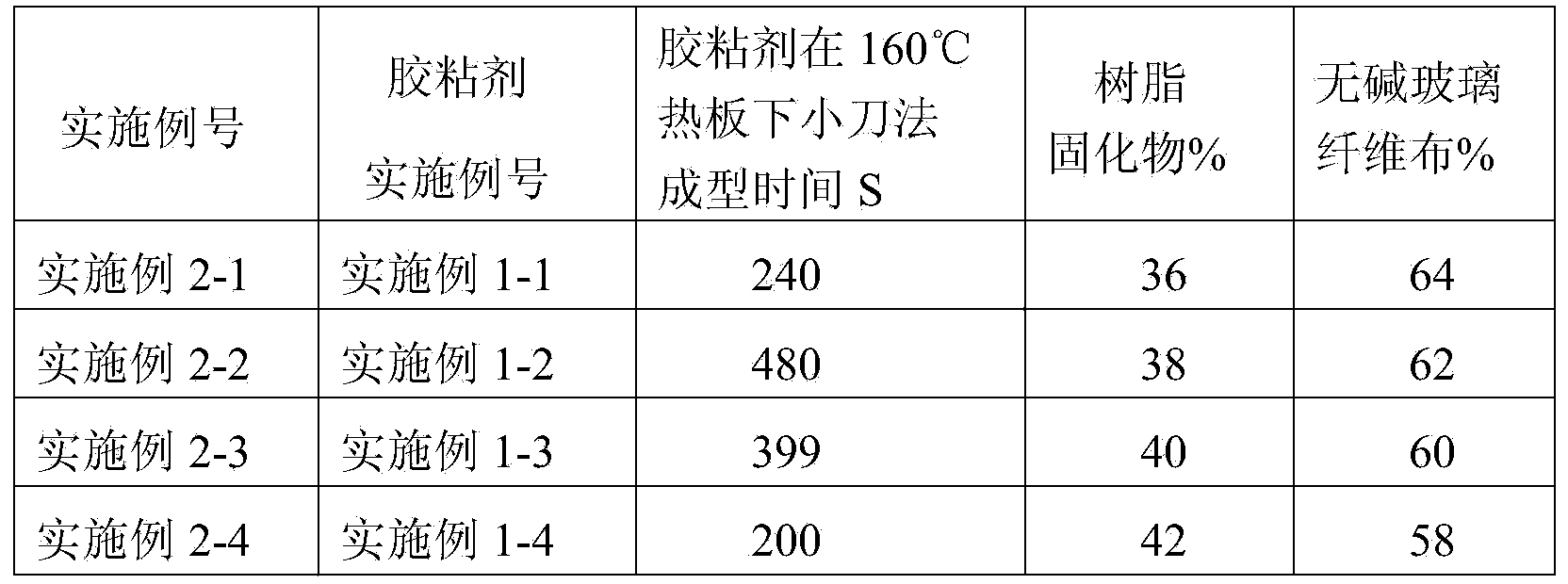

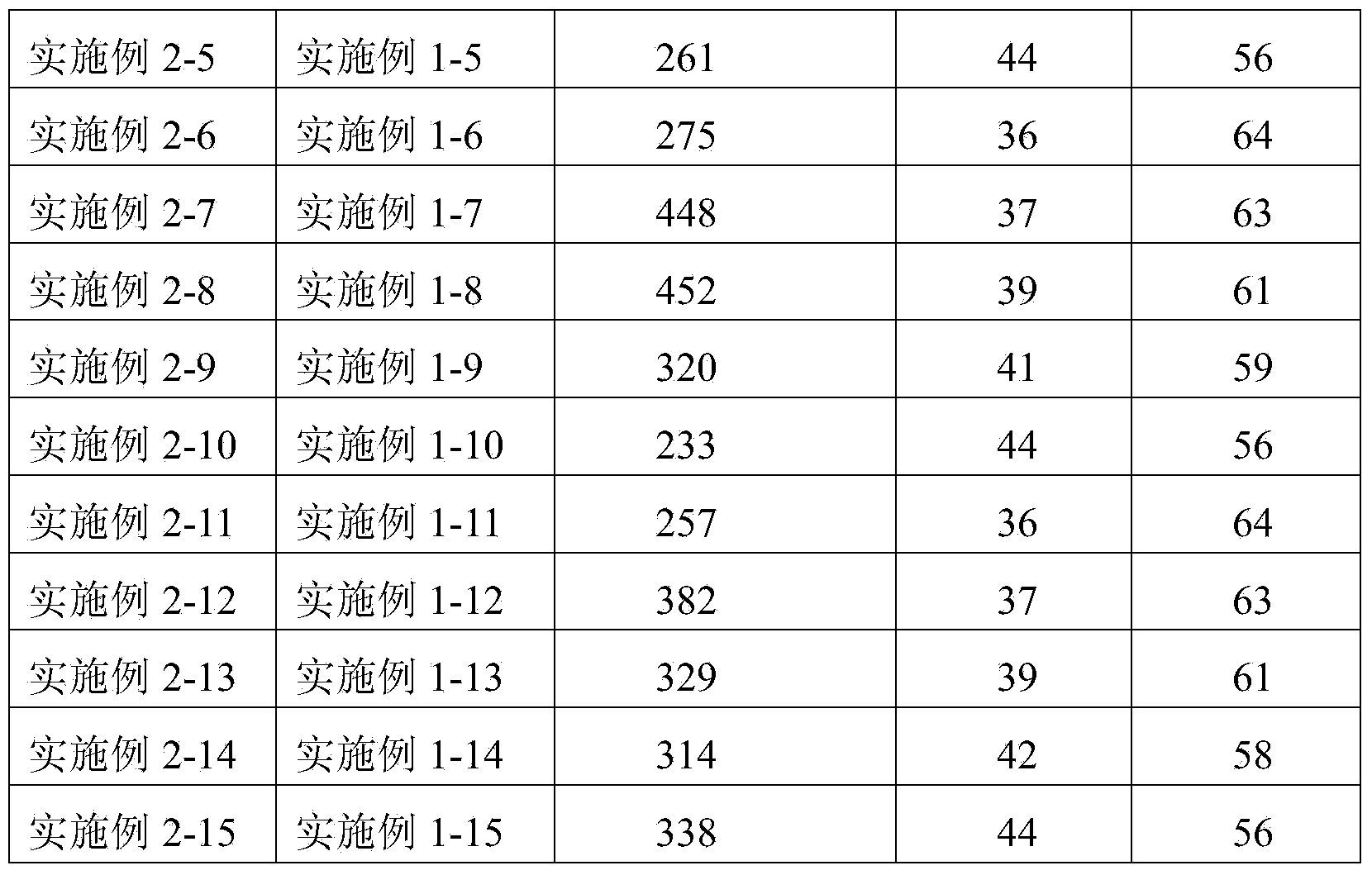

[0043] Preparation of the first part polyester-phenolic-epoxy adhesive

[0044] Basic raw materials:

[0045] Low-molecular-weight polyester resin is self-made polyethylene terephthalate, polytrimethylene terephthalate or polybutylene terephthalate with a weight-average molecular weight of 800 to 1200. method manufacturing. The cardanol-modified phenolic resin is self-made and manufactured by the method provided in the content of the present invention. The epoxy resin is E-44 produced by Yueyang Baling Petrochemical Company, and the nano-silica is the nano-silica produced by Shanghai Huijingya Nano New Material Co., Ltd.

Embodiment 1-1

[0047] Mix 20kg of polyethylene terephthalate with a weight average molecular weight of 800, 60kg of cardanol-modified phenolic resin and 140kg of mixed solvent (acetone: ethyl acetate: toluene: ethanol = 3:1:2:1) Add it into the reactor, stir at 40℃~60℃ for 1~2h, cool down to room temperature, add 45kg of epoxy resin, 0.5kg of nano-silicon dioxide, stir evenly, then add 2kg of hexamethylenetetramine, stir for 0.5 h, and make it fully dispersed and dissolved, then add 0.15kg accelerator (2-methylimidazole: 2-ethyl-4-methylimidazole = 1:2) to adjust the molding time of the mixture, under 160 ℃ hot plate The molding time of the small knife method is 240 seconds, and the preparation is completed.

Embodiment 1-2

[0049] Mix 20kg of polyethylene terephthalate with a weight average molecular weight of 800, 80kg of cardanol-modified phenolic resin and 210kg of mixed solvent (acetone: ethyl acetate: toluene: ethanol = 3:1:2:1) Add it into the reactor, stir at 40℃~60℃ for 1~2h, cool down to room temperature, add 55kg of epoxy resin, 3kg of nano-silicon dioxide, stir evenly, then add 2.5kg of hexamethylenetetramine, stir for 0.5 h, and make it fully dispersed and dissolved, then add 0.05kg accelerator (2-ethyl-4-methylimidazole: 2-undecylimidazole = 4:1) to adjust the molding time of the mixture, and heat it at 160°C The molding time of the small knife method under the plate is 480 seconds, and the preparation is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com