Application of borate compound serving as additive for high-voltage lithium-ion battery electrolyte

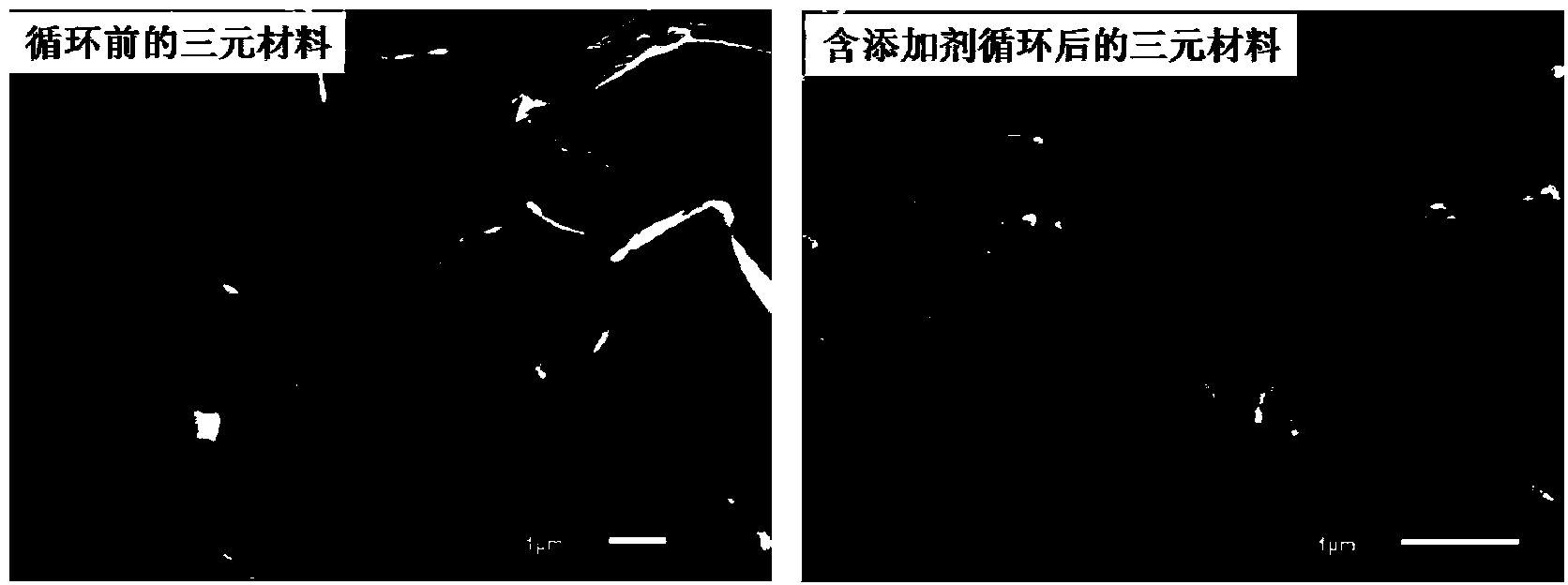

An electrolyte additive and lithium-ion battery technology, applied in the field of lithium-ion batteries, can solve the problems of battery charge-discharge cycle and other electrical performance decline, the structure of the positive electrode material is not stable enough, the shape of the positive electrode material changes, etc., to optimize the surface of the positive and negative electrodes Membrane, improve cycle stability, inhibit the effect of further exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

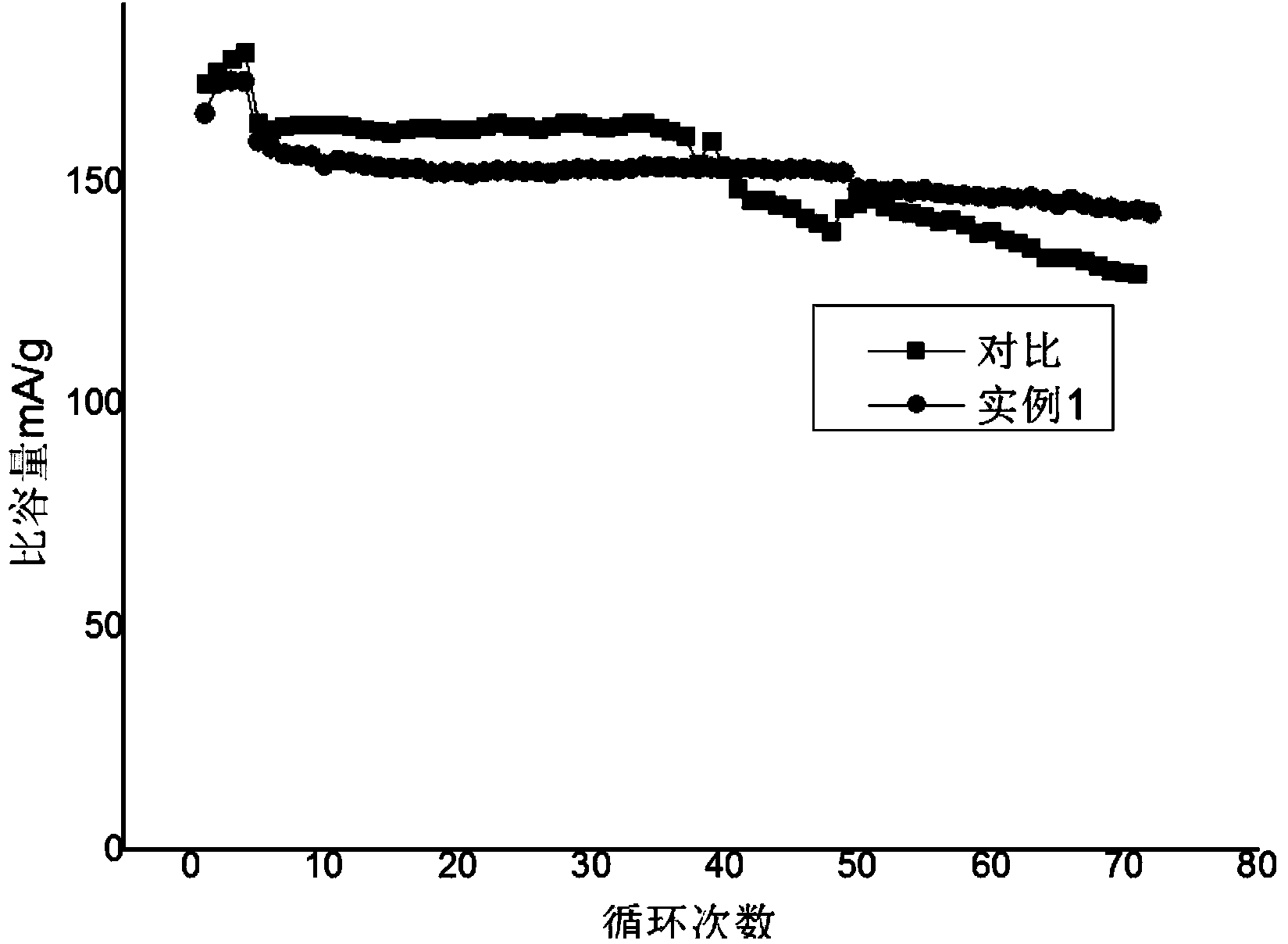

Embodiment 1

[0051] (1) The cyclic carbonate solvent ethylene carbonate (EC) and the linear carbonate solvent ethyl methyl carbonate (EMC) and diethyl carbonate (DEC) are mass ratio EC:EMC:DEC=1:3:2 mixed with molecular sieve Calcium hydride and lithium hydride are purified to remove impurities and water to obtain a mixed solvent;

[0052] (2) The conductive lithium salt LiPF 6 Dissolve in the mixed solvent that step (1) obtains, stir well, be made into common electrolyte; Wherein conductive lithium salt LiPF 6 The final concentration in ordinary electrolyte is 0.8mol / L;

[0053] (3) Triphenyl borate is added to the common electrolyte prepared in step (2), and the amount of triphenyl borate is 1% of the mass of the common electrolyte; a high-voltage lithium-ion battery electrolyte is obtained.

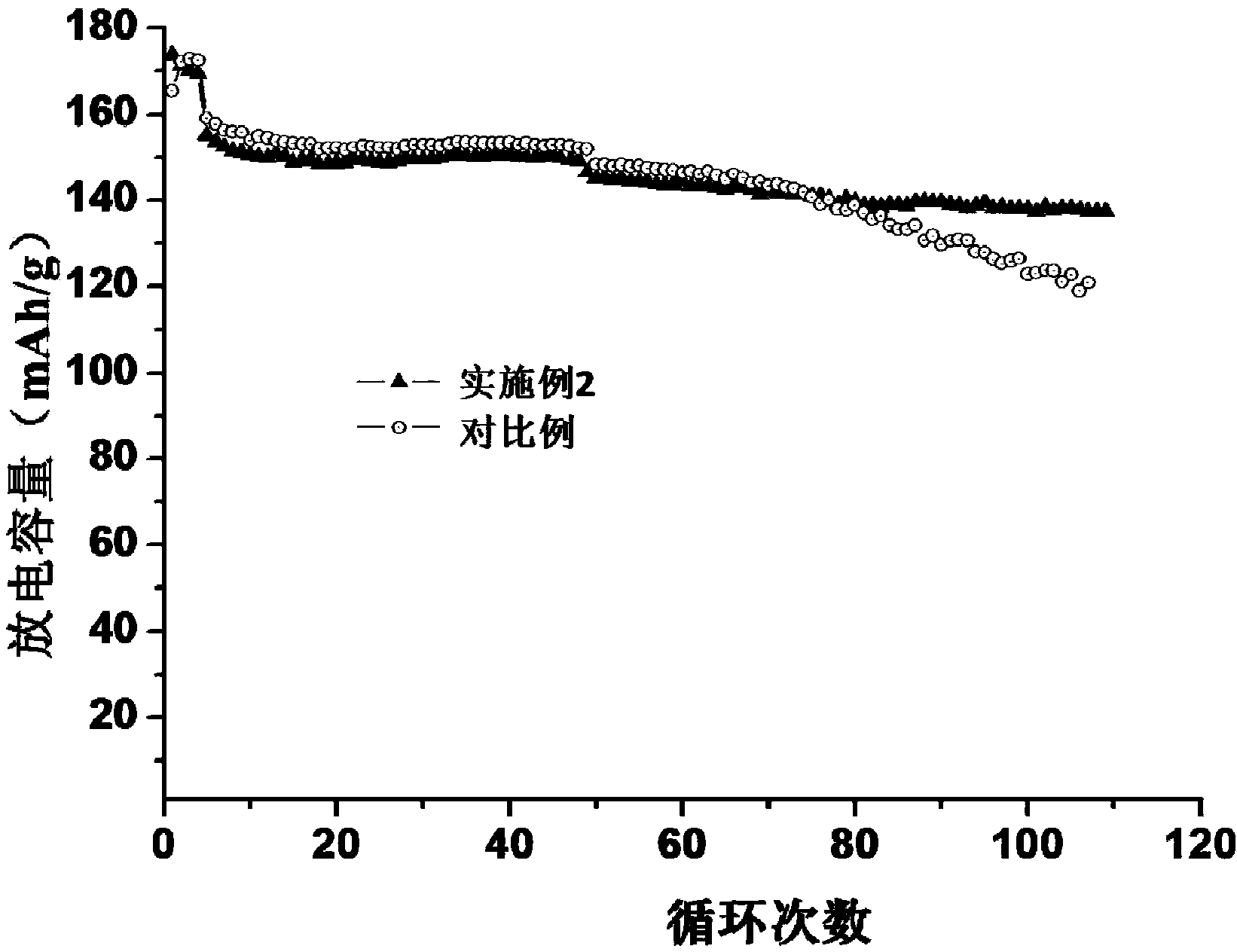

Embodiment 2

[0055] (1) Mix cyclic carbonate solvent ethylene carbonate (EC) and linear carbonate solvent ethyl methyl carbonate (EMC) and diethyl carbonate (DEC) according to the mass ratio EC:EMC:DEC=1:3:2 mixed with molecular sieve Calcium hydride and lithium hydride are purified to remove impurities and water to obtain a mixed solution;

[0056] (2) The conductive lithium salt LiPF 6 Dissolve in the mixed solvent that step (1) obtains, stir well, be made into common electrolyte; Wherein conductive lithium salt LiPF 6 The final concentration in ordinary electrolyte is 0.8mol / L;

[0057] (3) adding triethyl borate to the ordinary electrolyte prepared in step (2), the consumption of triethyl borate being 0.1% of the mass of the ordinary electrolyte; obtaining a high-voltage lithium-ion battery electrolyte.

Embodiment 3

[0059] (1) The cyclic carbonate solvent ethylene carbonate (EC) and the linear carbonate solvent ethyl methyl carbonate (EMC) and diethyl carbonate (DEC) are mass ratio EC:EMC:DEC=10:1:1 mixed with molecular sieve Calcium hydride and lithium hydride are purified to remove impurities and water to obtain a mixed solvent;

[0060] (2) The conductive lithium salt LiPF 6 Dissolve in the mixed solvent that step (1) obtains, stir well, be made into common electrolyte; Wherein conductive lithium salt LiPF 6 The final concentration in common electrolyte is 1.2mol / L;

[0061] (3) Add triethyl borate to the common electrolyte prepared in step (2), the consumption of triethyl borate is 5% of the quality of common electrolyte; obtain high-voltage lithium-ion battery electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com