Fermentation agent and preparation method of probiotics and straw fermented feed

A technology of fermented feed and production method, which is applied in the direction of animal feed, animal feed, application, etc., can solve the problems of insufficient utilization of straw nutrients, difficult to meet maintenance requirements, and inability to improve digestibility, and improve the utilization rate of feed. , The effect of reducing viscosity and stimulating appetite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

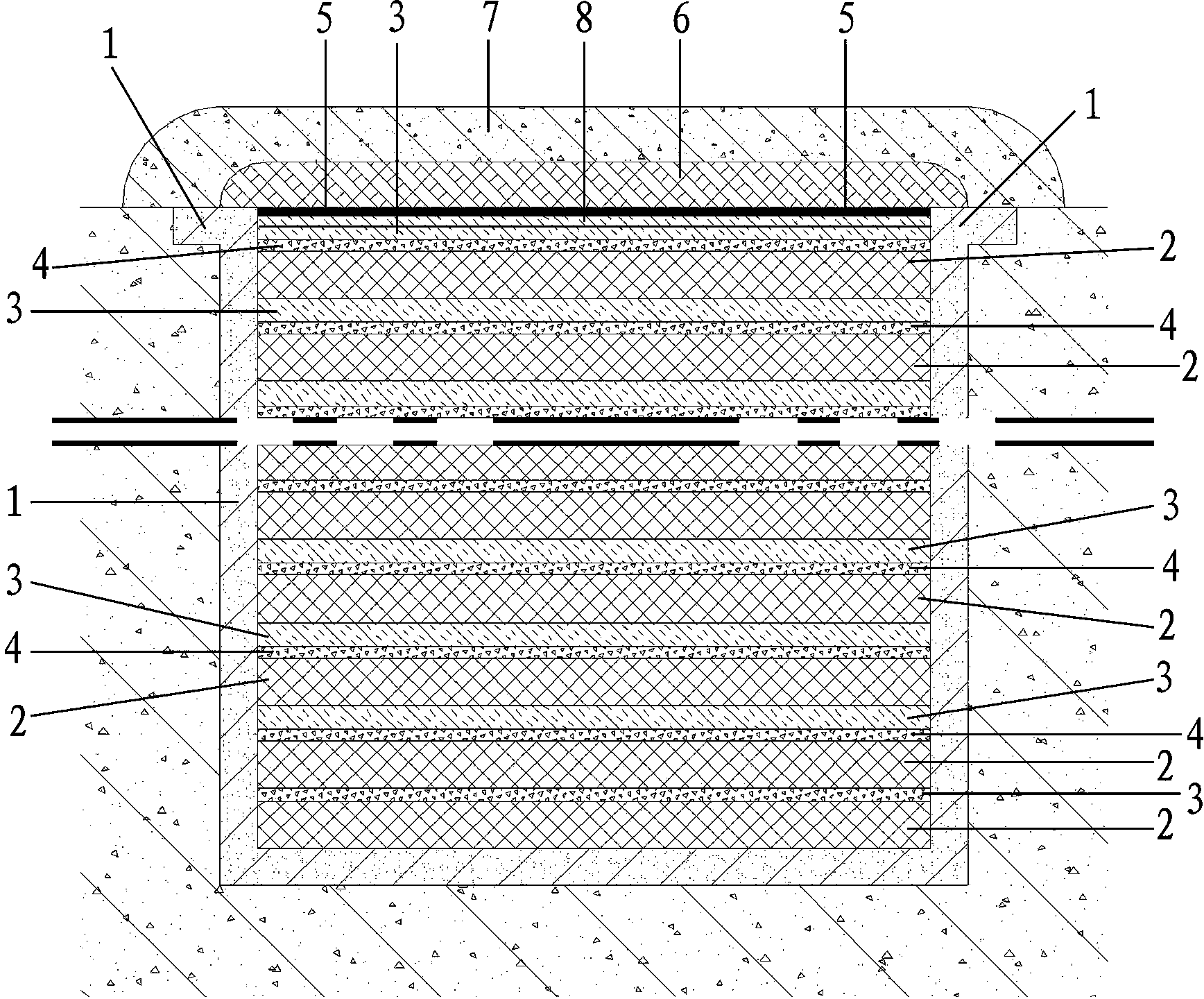

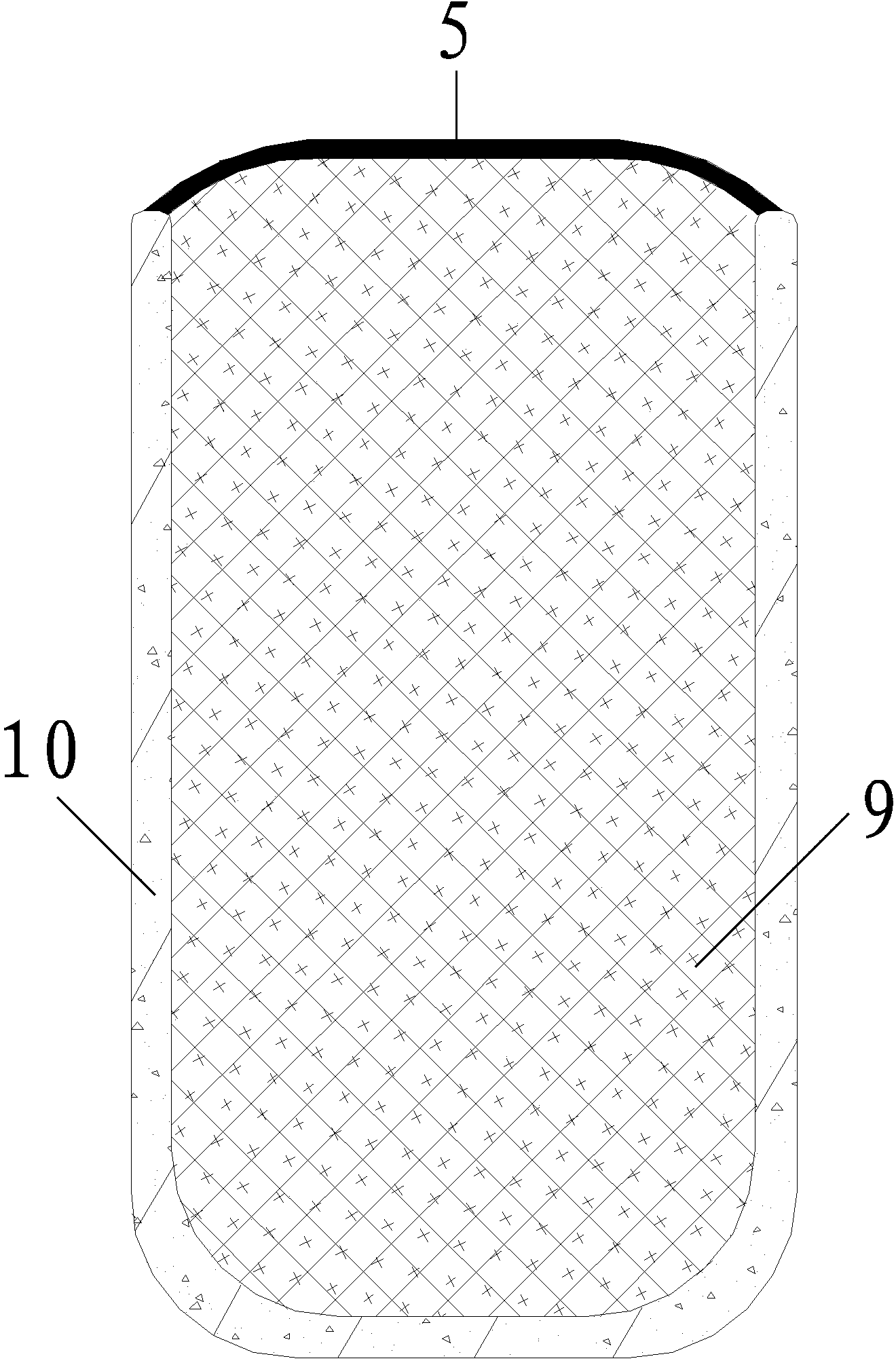

Method used

Image

Examples

Embodiment 1

[0105] Embodiment 1 (high dosage is calculated as 0.5g per part by weight)

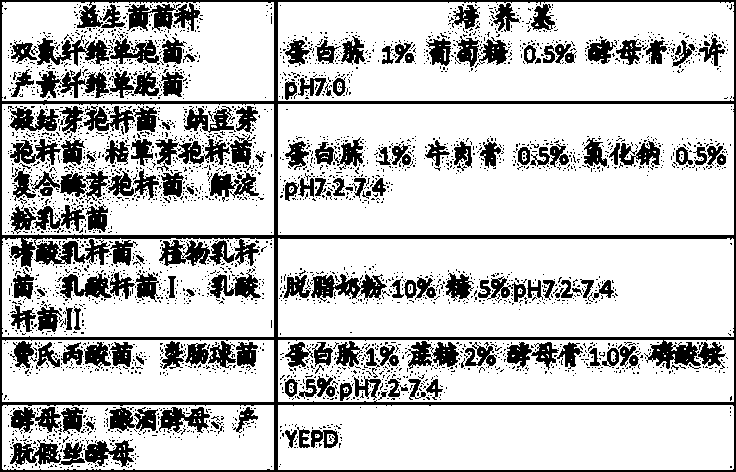

[0106] Ruminant fermented feed starter comprises the following components in proportion by weight:

[0107] Cellulomonas dinitrogenum 0.75g, Lactobacillus acidophilus 0.75g, Lactobacillus I 1.25g, Enterococcus faecalis 1g, Bacillus coagulans 0.75g, Bacillus subtilis 0.75g, Lactobacillus amyloliquefaciens 0.75g, propionic acid Bacillus 1.5g, yeast 0.75g. Embodiment 2 (low dose is calculated as 0.5g per part by weight)

Embodiment 2

[0107] Cellulomonas dinitrogenum 0.75g, Lactobacillus acidophilus 0.75g, Lactobacillus I 1.25g, Enterococcus faecalis 1g, Bacillus coagulans 0.75g, Bacillus subtilis 0.75g, Lactobacillus amyloliquefaciens 0.75g, propionic acid Bacillus 1.5g, yeast 0.75g. Embodiment 2 (low dose is calculated as 0.5g per part by weight)

[0108] Ruminant fermented feed starter comprises the following components in proportion by weight:

[0109] Cellulomonas dinitrogenum 0.25g, Lactobacillus acidophilus 0.25g, Lactobacillus Ⅰ 0.75g, Enterococcus faecalis 0.25g, Bacillus coagulans 0.25g, Bacillus subtilis 0.25g, Lactobacillus amyloliquefaciens 0.25g, C. fischeri Acid bacteria 0.75g, yeast 0.25g.

Embodiment 3

[0110] Embodiment 3 (moderate dose is calculated as 0.5g per part by weight)

[0111] The fermented feed starter for ruminants includes the following components by weight ratio: 0.5 g of Cellulomonas dinitrogen, 0.5 g of Lactobacillus acidophilus, 1 g of Lactobacillus I, 0.625 g of Enterococcus faecalis, 0.5 g of Bacillus coagulans, subtilis Bacillus 0.5g, Lactobacillus amyloliquefaciens 0.5g, Propionibacterium fresnerii 1.125g, yeast 0.5g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com