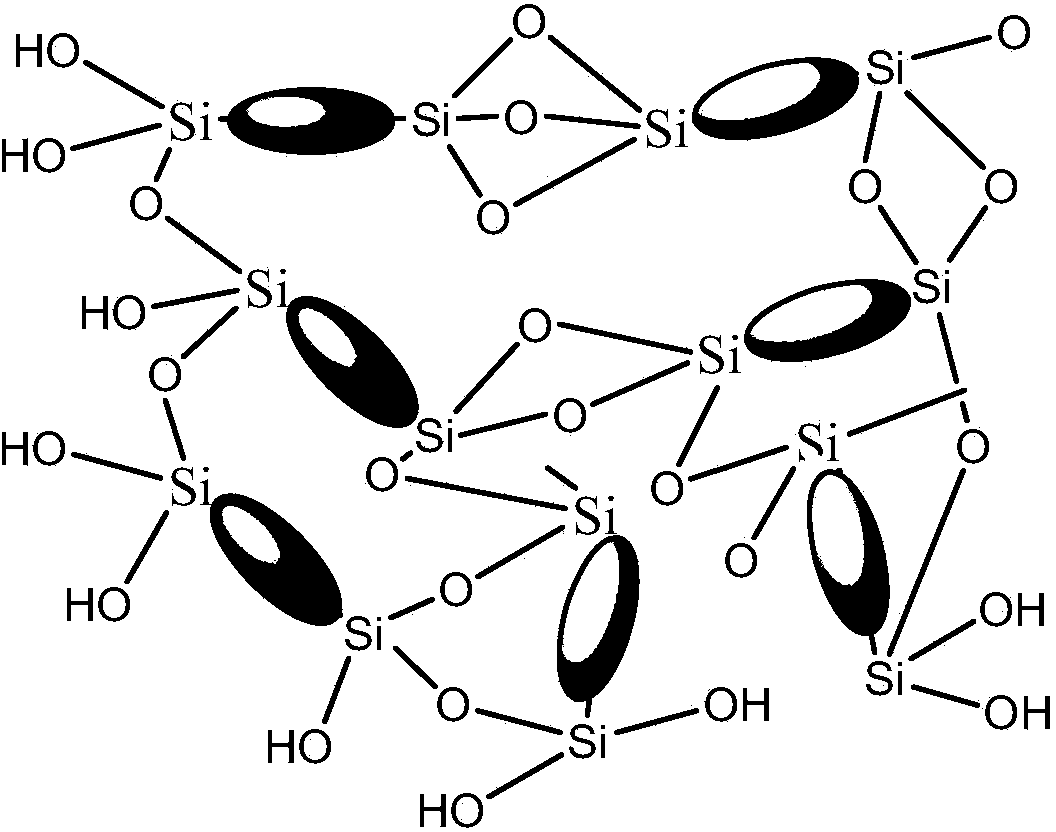

Reaction catalyst system for synthesizing bridged polysilsesquioxane microspheres and application thereof

A polysilsesquioxane, catalyst technology, applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, microsphere preparation, etc., can solve the problem of high size uniformity, low yield, Large size dispersion and other problems, to achieve the effects of high size uniformity, simple and easy process, and less side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1. Under nitrogen protection, under constant temperature conditions of 60°C, mix 60mL of ethanol with a volume concentration of 95% or more, 3mL of tetramethylammonium hydroxide and 100mL of ammonia water with a concentration of 5mol / L, and then stir evenly to obtain a mixed solution;

[0027] Step 2. Under the protection of nitrogen, under the condition of constant temperature stirring at 60 ° C, 50 mL of bridging bistrimethoxysilane (1,2-bis(trimethoxysilyl) ethane with ethyl as the bridging group) ) was added dropwise to the mixed solution described in step 1, and after the dropwise addition was completed, reflux and stirred for 12h, and then the reaction solution was filtered to obtain a white solid crude product; the 1,2-bis(trimethoxysilyl)ethane Molecular formula is

[0028] Step 3. Wash the crude white solid product described in step 2 with deionized water and acetone three times in sequence, and then vacuum-dry the crude white solid product after washing...

Embodiment 2

[0031] Step 1. Under nitrogen protection, under constant temperature conditions of 50°C, mix 80mL of ethanol with a volume concentration of 95% or more, 4mL of tetramethylammonium hydroxide and 80mL of ammonia water with a concentration of 10mol / L, and then stir evenly to obtain a mixed solution;

[0032] Step 2, under the protection of nitrogen, under the condition of constant temperature stirring at 50 ° C, 60 mL of bridged bistrichlorosilane (1,8-bis(trichlorosilyl) n-octane) with n-octyl as the bridging group ) was added dropwise to the mixed solution described in step 1, and after the dropwise addition was completed, reflux and stirred for 15 hours, and then the reaction solution was filtered to obtain a white solid crude product; the 1,8 - The molecular formula of bis(trichlorosilyl)-n-octane is

[0033] Step 3. Wash the crude white solid product described in step 2 with deionized water and acetone four times in sequence, and then vacuum-dry the crude white solid produ...

Embodiment 3

[0036] Step 1. Under nitrogen protection, under constant temperature conditions of 70°C, mix 90mL of acetone with a volume concentration of 95% or more, 5mL of tetraethylammonium hydroxide and 100mL of ammonia water with a concentration of 3mol / L, and then stir evenly to obtain a mixed solution;

[0037] Step 2. Under the protection of nitrogen, under the condition of constant temperature stirring at 70 ° C, 100 mL of bridged bistrimethoxysilane (1,4-bis(trimethoxysilyl) benzene) with phenyl as the bridging group Add it dropwise to the mixed solution described in step 1, reflux and stir for 5 hours after the dropwise addition is completed, then filter the reaction solution to obtain a white solid crude product; the molecular formula of the 1,4-bis(trimethoxysilyl)benzene is

[0038] Step 3. The white solid crude product described in step 2 is washed twice with deionized water and acetone in turn, and then the washed white solid crude product is vacuum-dried to obtain a white po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com