Hydrophobic and oleophobic silica-based translucent coating film and preparation method thereof

A silica-based, light-transmitting coating technology, applied in the field of self-cleaning optical materials and new materials, can solve the problems of harsh operating conditions, expensive equipment, complex process routes, etc., to simplify the production process, facilitate industrial production, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

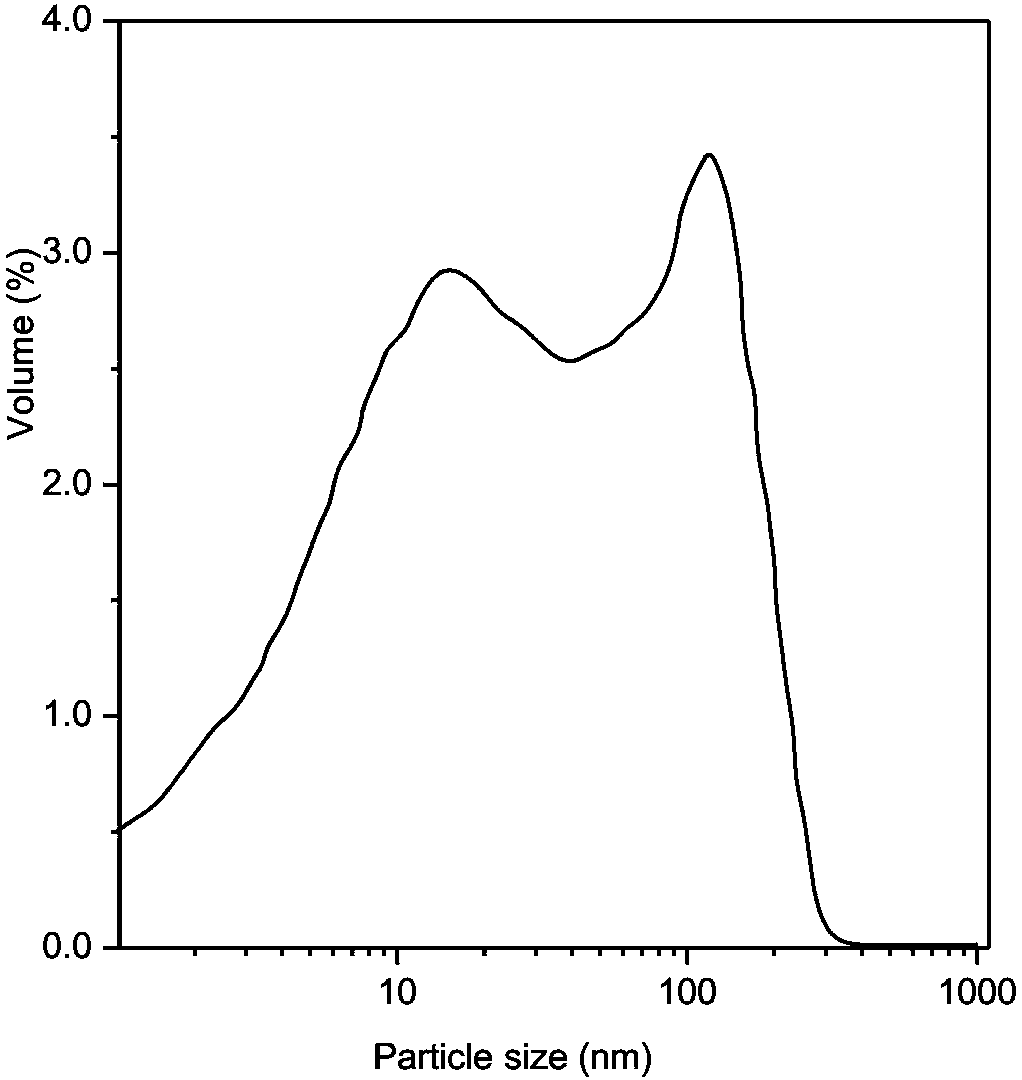

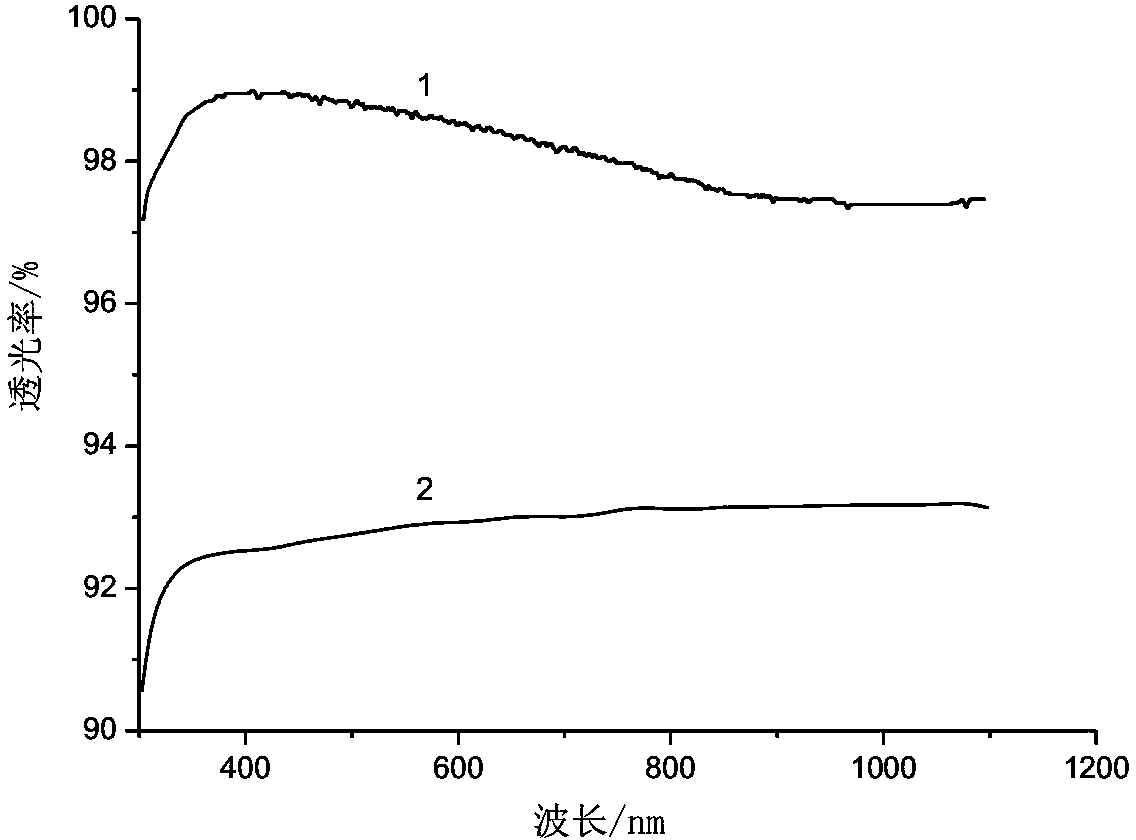

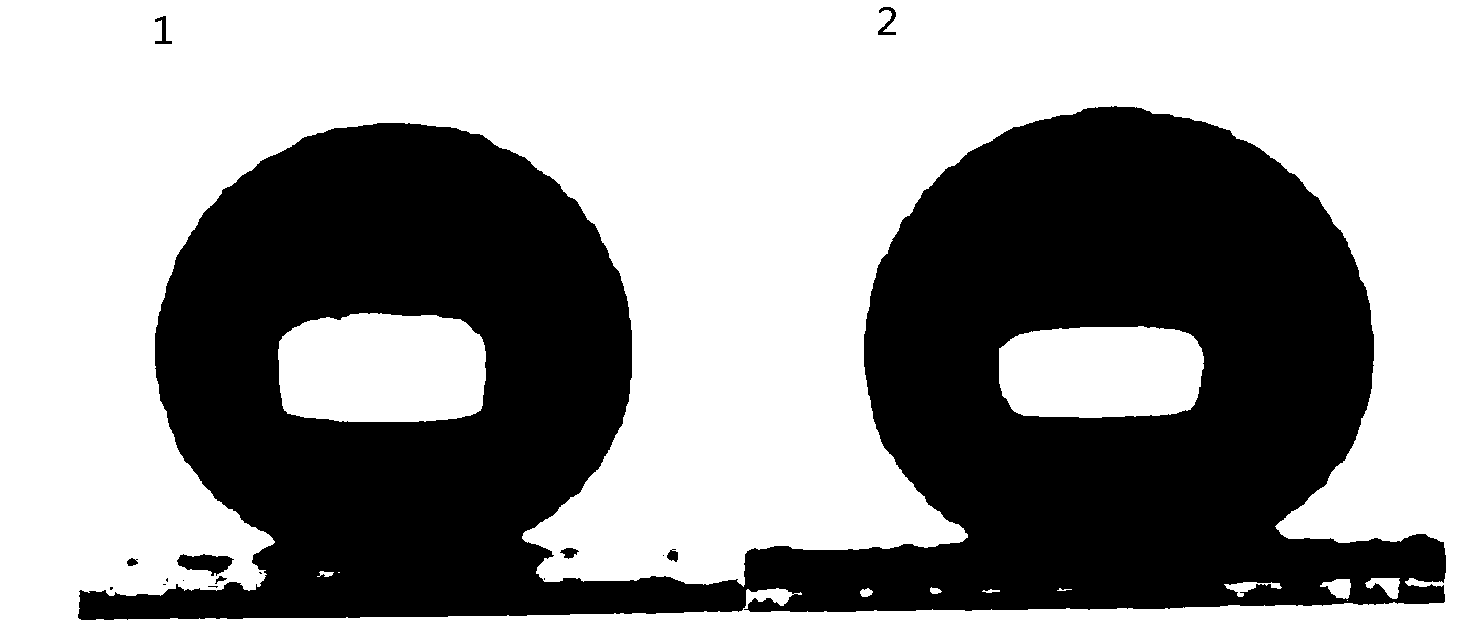

[0021] This example is the preparation of a hydrophobic and oleophobic silica-based light-transmitting coating film. The specific process is: use concentrated sulfuric acid (98wt%) and hydrogen peroxide (30wt%) aqueous solution to prepare a glass washing solution at a volume ratio of 3:1, soak the glass substrate in the glass washing solution for 5 minutes, and then wash it in deionized water and acetone respectively. Ultrasonic for 20 minutes, then treated with 5 mol / L sodium hydroxide aqueous solution at room temperature for 5 minutes, washed with deionized water, and dried by blasting at room temperature to obtain an activated glass substrate; take 40 mL of absolute ethanol, divide it into two parts, and add 2 mL of orthosilicon to one part Acid ethyl ester (Si(OCH 2 CH 3 ) 4 ), add 1mL glacial acetic acid (AR) dropwise while stirring, and stir for 1h to obtain solution A; add 8mL concentrated ammonia water (25wt%) to another part of absolute ethanol, stir well to obtain ...

Embodiment 2

[0023] This example is the preparation of a hydrophobic and oleophobic silica-based light-transmitting coating film. The specific process is: use concentrated sulfuric acid (98wt%) and hydrogen peroxide (30wt%) aqueous solution to prepare a glass washing solution at a volume ratio of 3:1, soak the glass substrate in the glass washing solution for 5 minutes, and then wash it in deionized water and acetone respectively. Ultrasonic for 20 minutes, then treated with 5 mol / L sodium hydroxide aqueous solution at room temperature for 5 minutes, washed with deionized water, and dried by blasting at room temperature to obtain an activated glass substrate; take 60 mL of absolute ethanol, divide it into two parts, and add 3 mL of orthosilicon to one part Acid ethyl ester (Si(OCH 2 CH 3 ) 4), add 1mL glacial acetic acid (AR) dropwise while stirring, and stir for 2 hours to obtain solution A; add 9mL concentrated ammonia water (25wt%) to another part of absolute ethanol, and stir evenly ...

Embodiment 3

[0025] This example is the preparation of a hydrophobic and oleophobic silica-based light-transmitting coating film. The specific process is: use concentrated sulfuric acid (98wt%) and hydrogen peroxide (30wt%) aqueous solution to prepare a glass washing solution at a volume ratio of 3:1, soak the glass substrate in the glass washing solution for 5 minutes, and then wash it in deionized water and acetone respectively. Ultrasonic for 20 minutes, then treated with 5 mol / L sodium hydroxide aqueous solution at room temperature for 5 minutes, washed with deionized water, and air-dried at room temperature to obtain an activated glass substrate; take 50 mL of absolute ethanol, divide it into two parts, and add 4 mL of orthosilicon to one part Acid ethyl ester (Si(OCH 2 CH 3 ) 4 ), add 1mL glacial acetic acid (AR) dropwise while stirring, and stir for 1.5h to obtain solution A; into solution B, and stirred for 1.5 hours to obtain a double-particle-diameter nano-silica sol; to the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com