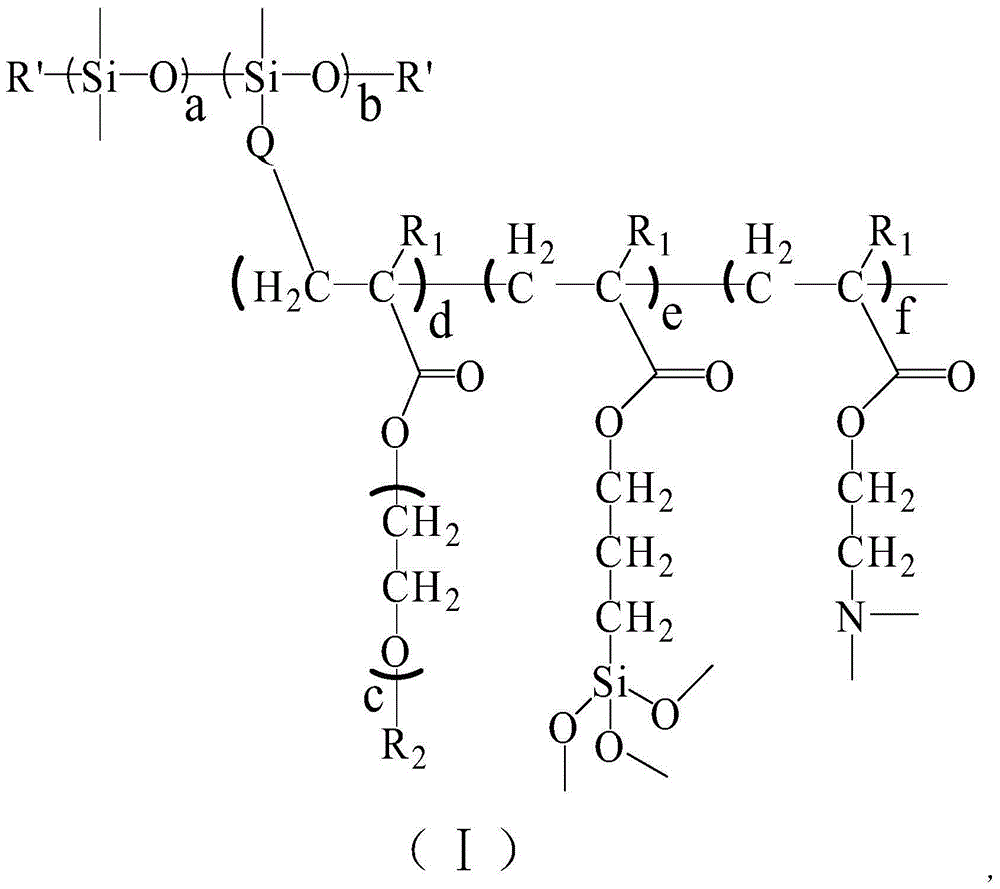

Organic silicon graft copolymer and its preparation method and application

A technology of graft copolymer and silicone, which is applied in the field of silicone graft copolymer and its preparation, can solve the problems of poor water solubility and poor durability of the coating, and achieve improved crosslinking degree, excellent hydrophilicity, and excellent composition Effect of Membrane Properties and Water Repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

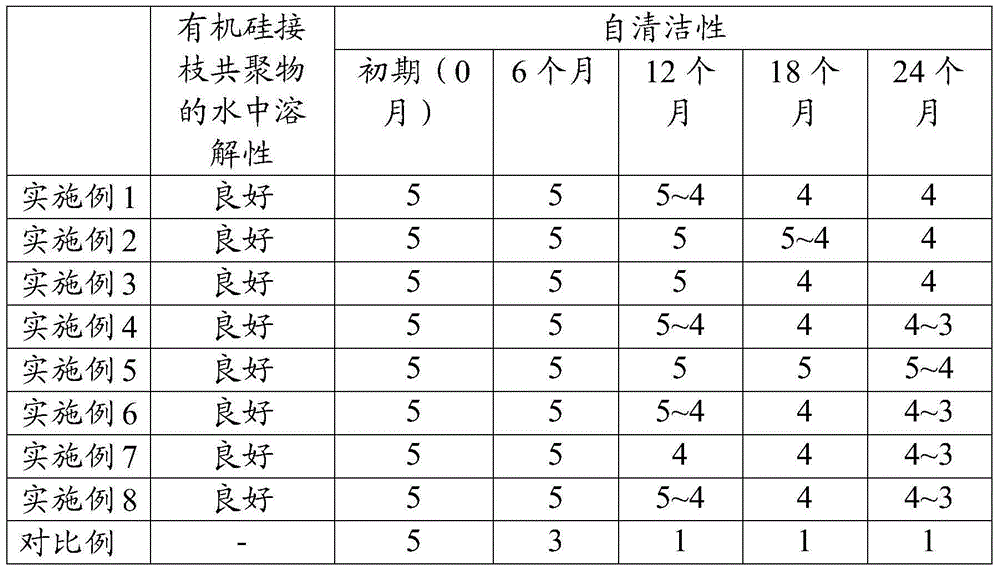

Examples

Embodiment 1

[0033] This embodiment provides a kind of organosilicon graft copolymer, and its specific preparation method is:

[0034] S1. Add 50g of monomer to be polymerized A1, 10g of monomer to be polymerized A2, 35g of monomer to be polymerized A3 and 5g of monomer to be polymerized A4 in a 500ml four-necked flask, add 100g of dipropylene glycol monomethyl ether to dissolve the above monomer to be polymerized Body, add 2g initiator azobisisobutyronitrile;

[0035] Nitrogen was introduced to reduce the oxygen content in the four-necked flask to below 500ppm, and the temperature was raised to 80°C. After 18 hours of reaction, the monomer conversion rate was monitored by gas chromatography. When the monomer conversion rate reached 98%, the heating reaction was terminated.

[0036]A1 is mercapto-containing polydimethylsiloxane (XIAMETER OFS-2396), A2 is N,N-dimethylaminoethyl methacrylate, A3 is polyethylene glycol (EO10mol) monomethacrylate, A4 It is γ-(methacryloyloxy)propyltrimethoxys...

Embodiment 2

[0042] This embodiment provides a kind of organosilicon graft copolymer, and its specific preparation method is:

[0043] S1, add 50g monomer to be polymerized A1, 10g monomer to be polymerized A2, 35g monomer to be polymerized A3 and 5g monomer to be polymerized A4 in a 500ml four-necked flask, add 67g of dipropylene glycol and triglycerol in a mass ratio of The mixture of 1:1 dissolves the above-mentioned monomers to be polymerized, and adds 3g of initiator azobisisobutyronitrile;

[0044] Nitrogen was introduced to reduce the oxygen content in the four-neck flask to below 500ppm, and the temperature was raised to 25°C. After 18 hours of reaction, the monomer conversion rate was monitored by gas chromatography. When the monomer conversion rate reached 99%, the heating reaction was terminated.

[0045] A1 is acrylate-containing polydimethylsiloxane (XIAMETER OFS-4246), A2 is N,N-dimethylaminoethyl methacrylate, A3 is polyethylene glycol (EO10mol) monomethacrylate, A4 is γ-(m...

Embodiment 3

[0050] This embodiment provides a kind of organosilicon graft copolymer, and its specific preparation method is:

[0051] S1. Add 30g of monomers to be polymerized A1, 20g of monomers to be polymerized A2, 45g of monomers to be polymerized A3 and 5g of monomers to be polymerized A4 in a 500ml four-necked flask, add 100g of dipropylene glycol monomethyl ether to dissolve the above monomers to be polymerized Body, add 0.2g initiator azobisisobutyronitrile;

[0052] Nitrogen was introduced to reduce the oxygen content in the four-necked flask to below 500ppm, and the temperature was raised to 110°C. After 18 hours of reaction, the monomer conversion rate was monitored by gas chromatography. When the monomer conversion rate reached 98%, the heating reaction was terminated.

[0053] A1 is mercapto-containing polydimethylsiloxane (XIAMETER OFS-2397), A2 is N,N-dimethylaminoethyl methacrylate, A3 is polyethylene glycol (EO15mol) monomethacrylate, A4 It is γ-(methacryloyloxy)propyltr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com