Sulphonic acid type water-based unsaturated polyester and application of sulphonic acid type water-based unsaturated polyester in coating

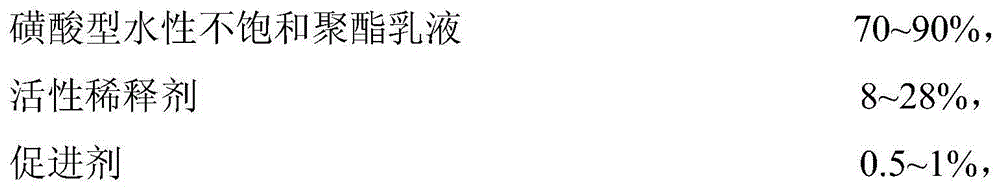

An unsaturated, sulfonic acid type technology, used in polyester coatings, coatings, etc., can solve the problems of low hardness, poor gloss, low solid content, etc., and achieve the effects of high hardness, reduced volatilization rate, and high fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Sulfonic acid type aqueous unsaturated polyester emulsion of the present invention is prepared by the following method:

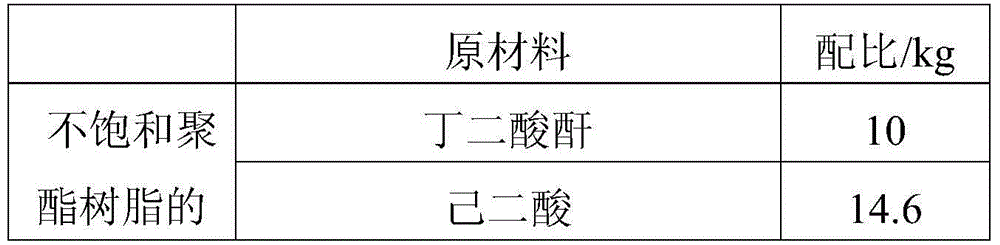

[0048] Step 1: Composition and ratio

[0049] According to the formula shown in table 1

[0050] Step 2: Synthesis of unsaturated polyester prepolymer

[0051] Dibasic alcohols, saturated dibasic acids, saturated acid anhydrides and unsaturated dibasic acids, that is, the raw materials listed in Table 1, succinic anhydride, adipic acid, phthalic anhydride, maleic acid, triethylene glycol, Put 1,4-butanediol into the reaction kettle, heat up to 120±2°C, add xylene, polymerization inhibitor hydroquinone and antioxidant triphenyl phosphite, start stirring after the reactants are completely dissolved, and keep warm for 1 hour; Continue to heat up to 160±2°C, keep warm for 2 hours while maintaining reflux; continue to heat up to 190±2°C, keep warm for 6 hours and use the water separator to remove water at the same time;

[0052] Step 3: Preparation of ...

Embodiment 2

[0061] Sulfonic acid type aqueous unsaturated polyester emulsion of the present invention is prepared by the following method:

[0062] Step 1: Composition and ratio

[0063] According to the formula shown in table 2

[0064] Step 2: Synthesis of unsaturated polyester prepolymer

[0065] According to the formula shown in Table 2, put diol, saturated acid anhydride and unsaturated acid anhydride into the reaction kettle, raise the temperature to 110±2°C, add xylene, polymerization inhibitor and antioxidant, start stirring after the reactants are completely dissolved, and keep warm for 1 Hours; continue to heat up to 170±2°C, keep warm for 2 hours and maintain reflux, then continue to heat up to 200±2°C, keep warm for 7 hours and use the water separator to remove water at the same time;

[0066] Step 3: Preparation of sulfonic acid type water-based unsaturated polyester

[0067] Add the water-based monomer shown in Table 2 and raise the temperature to 235±2°C at the same time...

Embodiment 3

[0074] Sulfonic acid type aqueous unsaturated polyester emulsion of the present invention is prepared by the following method:

[0075] Step 1: Composition and ratio

[0076] According to the formula shown in table 3

[0077] Step 2: Synthesis of unsaturated polyester prepolymer

[0078] According to the formula shown in Table 3, put diol, saturated acid anhydride and unsaturated dibasic acid into the reactor, raise the temperature to 115±2°C, add xylene, polymerization inhibitor and antioxidant, and start stirring after the reactants are completely dissolved. Keep warm for 2 hours; continue to heat up to 150±2°C, keep warm for 3 hours and keep reflux, then continue to heat up to 205±2°C, keep warm for 7 hours and use the water separator to remove water at the same time;

[0079] Step 3: Preparation of sulfonic acid type water-based unsaturated polyester

[0080] Add the water-based monomer shown in Table 3 and raise the temperature to 230±2°C at the same time, keep it warm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com