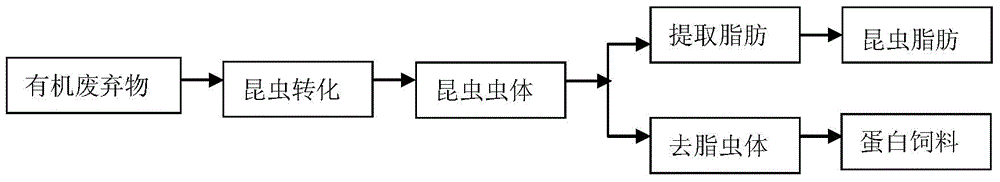

Material separation method for conversion from edible insect bodies to organic waste

A technology for the separation of organic waste and substances, which is applied in the preparation of organic fertilizers, the treatment of biological organic parts, and organic fertilizers. The effect of considerable benefits, easy promotion, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

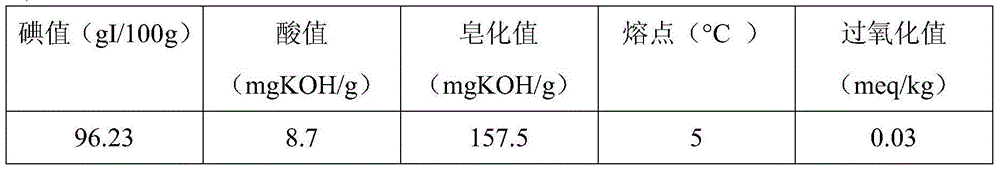

Examples

Embodiment 1

[0023] A method for separating edible insect soldier flies into organic waste and insect matter, the steps of which are:

[0024] Soldier Fly Larvae Cultivation: Soldier Fly Larvae Cultivation: The Soldier Fly Bright Spot is a Wuhan Strain, which was domesticated and bred from the wild population in Wuhan in this experiment. The method of collecting eggs and raising larvae of the Wuhan Strain of Soldier Fly Bright Spot According to the approved patent (A domestication and breeding method and application of a Wuhan strain of flat horned soldier fly, CN201110191867.6). Transfer the mixture of larvae and feed to a beaker, and use a small spoon to gently scoop off the rest of the feed on the surface. Soldier fly larvae have the habit of clustering and photophobia, and they will automatically drill down to clean out relatively clean larvae; the larvae counting method first mixes the separated larvae thoroughly, and randomly picks more than 200 larvae for weighing , counting the to...

Embodiment 2

[0040] Embodiment 2: Taking Tenebrio molitor as an example to transform crop stalk oil and protein feed:

[0041] The most important thing for raising Tenebrio molitor is to have species: adult larvae, pupae, and adults can all be used as species. Breeding to different insect stages, according to the breeding technology of Tenebrio molitor, carefully select pupae and adults, and sieve eggs, so that each insect stage can reproduce synchronously. After careful selection and breeding, all stages of insects can be used as seed insects for reproduction, but it is better to use adult larvae as seed insects. The growth rate of larvae and the length of the larval stage depend on temperature, humidity and feed. In general, the higher the temperature, the shorter the juvenile period, the specific temperature is 25-28°C, and the relative humidity is 60-70%.

[0042] Tenebrio molitor has strong adaptability, easy to master breeding technology, both industrial farming and decentralized b...

Embodiment 3

[0050] Embodiment 3: prepare crude fat and protein by transforming the insect body of livestock and poultry manure with housefly larvae:

[0051] The most important thing about housefly larvae is that there are seed worms: mature larvae, pupae, and adults can all be used as seed worms. Adult flies were fed with a mixture of milk powder:brown sugar:water (1:1:5), and the drinking water was changed every day. The fresh pig manure collected on the day and the compound feed were prepared (10:1) to form the egg collection information object and the oviposition bed, and the eggs collected every 24 hours were inoculated in the fresh pig manure collected on the day. Breed to different insect stages, according to the cultivation technology of housefly larvae, carefully select pupae and adults, remove diseased insects, sieve eggs, and make each insect stage reproduce synchronously. The water content of livestock and poultry feces is about 70-81%. After culturing at room temperature (24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com