Method for growing single-layer molybdenum disulfide by chemical vapor deposition

A single-layer molybdenum disulfide, chemical vapor deposition technology, applied in chemical instruments and methods, from chemically reactive gases, crystal growth, etc., can solve the problems of large area, low sample quality, poor repeatability, etc., to achieve high quality, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The method for preparing monolayer molybdenum disulfide by chemical vapor deposition comprises the following steps:

[0026] ① Pretreatment of the growth substrate for implanting seeds: Take a drop of 0.1mg / ml 3,4,9,10-perylenetetracarboxylic dianhydride or 3,4,9,10-perylenetetracarboxylic acid tetrapotassium salt Seed solution, drop on the surface of a pure growth substrate (silicon wafer or quartz wafer with a 300nm thick oxide layer); place the growth substrate on a spin coater, set the spin coater speed to 3000r / min, spin coat time For 3min, the growth substrate is placed in a vacuum drying oven after spin coating and stored for later use;

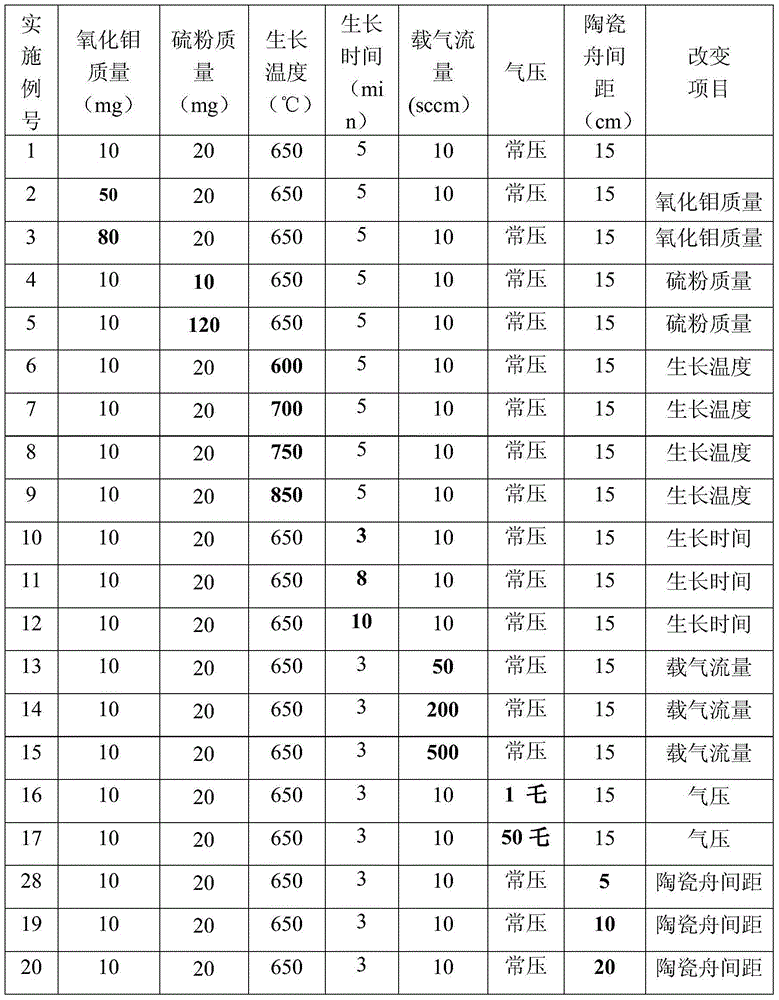

[0027] ② Pretreatment of precursors (sulfur powder and molybdenum oxide powder): Weigh 20 mg of sulfur powder and 10 mg of molybdenum oxide powder, and store them in a vacuum oven at 60°C for 12 hours;

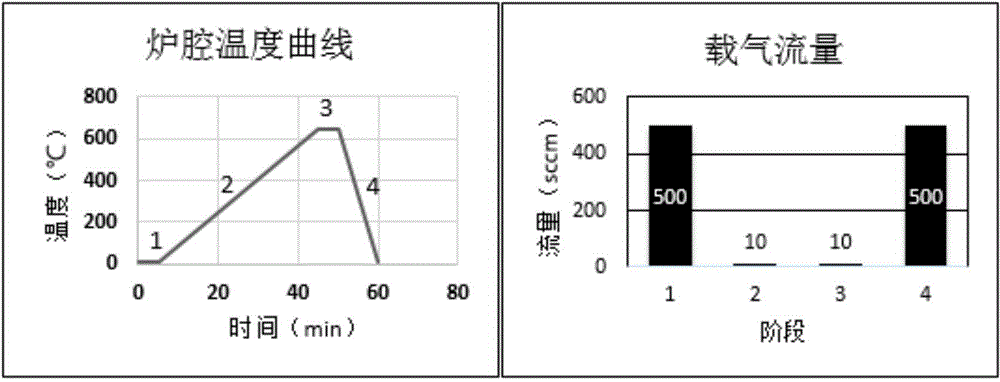

[0028] ③Put the precursor into the vacuum tube furnace to prepare for growth: evenly disperse the molybdenum oxide in the cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com