Low temperature resistant fuel gas heat pump air-conditioning system combiningwaste heat recovery mode and liquid dehumidification mode

A technology of solution dehumidification and waste heat recovery, which is applied in air conditioning systems, machines using waste heat, heating and refrigeration combinations, etc., can solve the problems of low grade of gas engine exhaust energy and difficulty in recovery, so as to prevent frosting, improve adaptability, The effect of increasing the COP value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

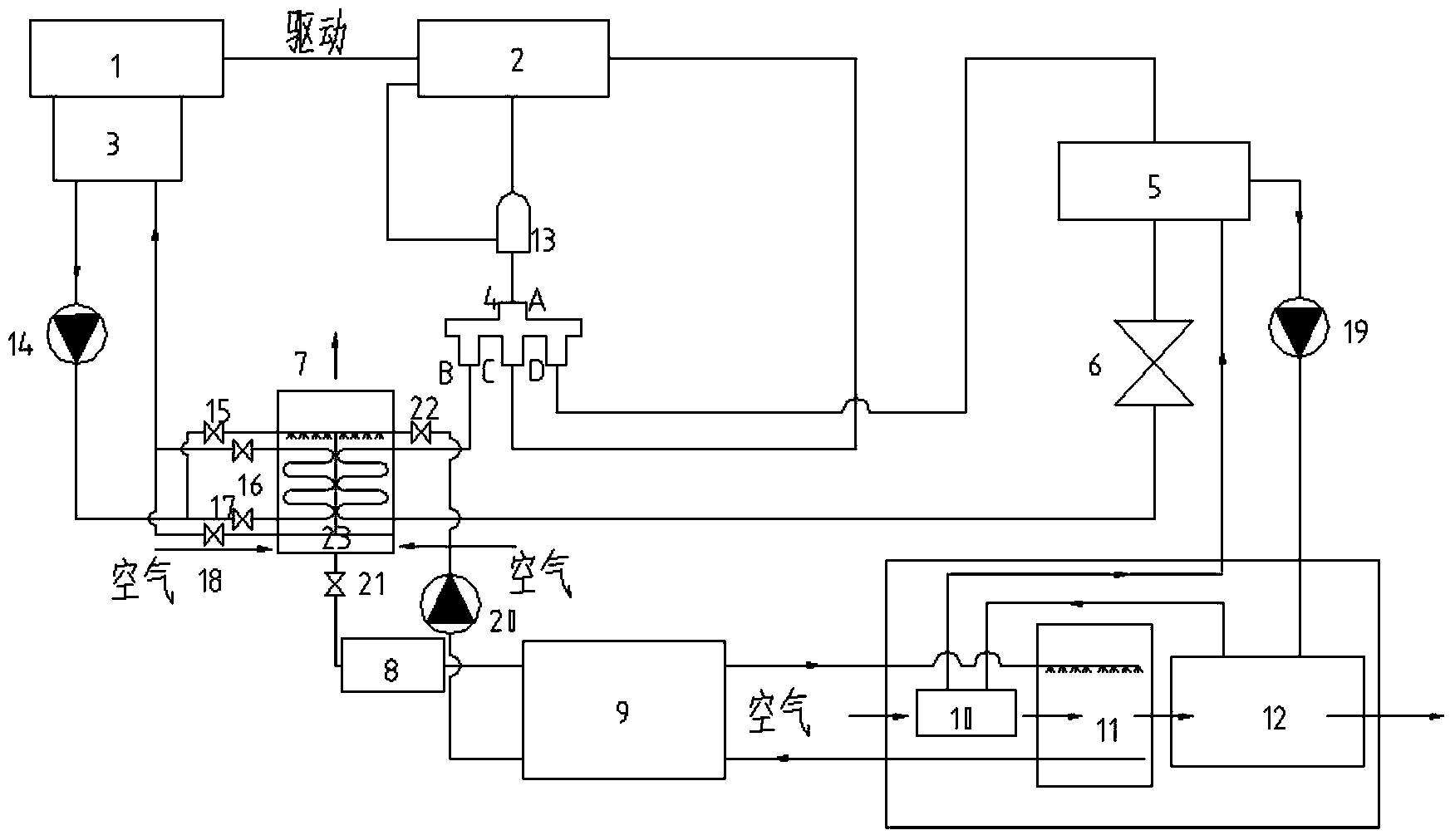

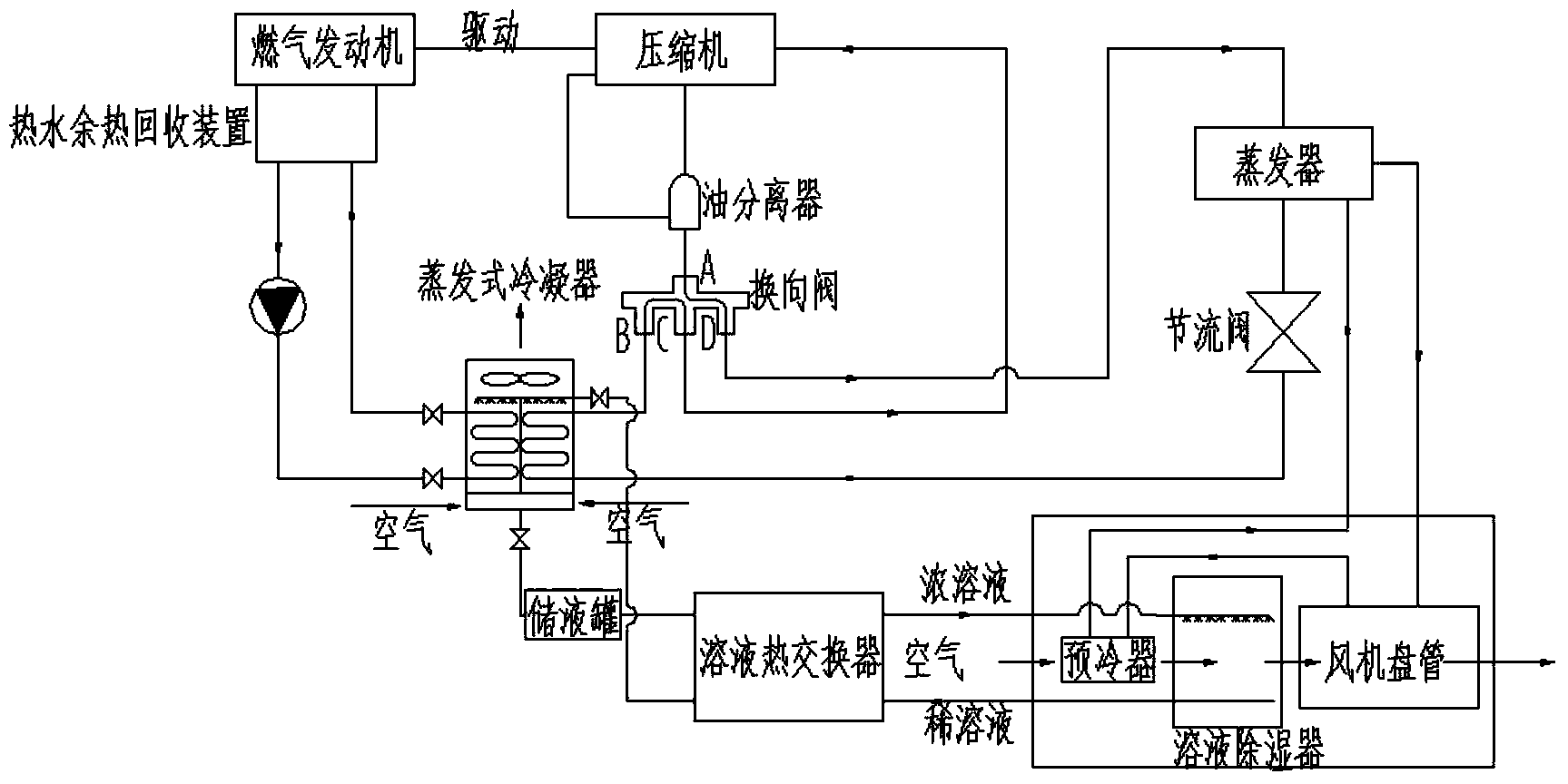

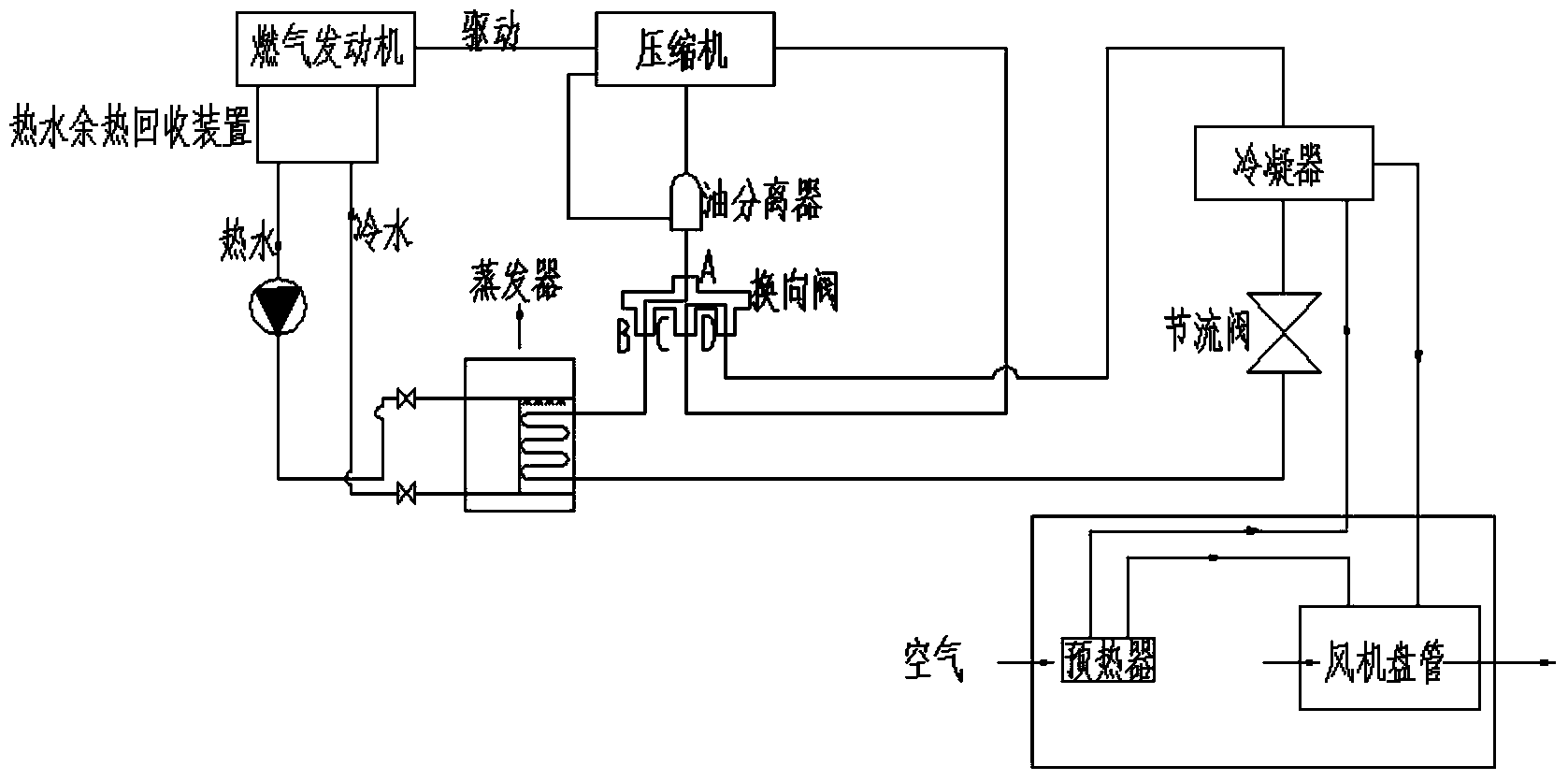

[0020] Such as figure 1 As shown, the system is mainly composed of gas engine 1, compressor 2, hot water waste heat recovery device 3, four-way reversing valve 4, heat exchanger 5, throttle valve 6, heat exchanger 7, liquid storage tank 8, solution Heat exchanger 9, preprocessor 10, dehumidifier 11, fan coil unit 12, oil separator 13, cooling water pump 14, first stop valve 15, second stop valve 16, third stop valve 17, fourth stop valve 18. Water pump 19 and solution pump 20 form.

[0021] Under the cooling condition in summer, the inlet port A of the four-way reversing valve 4 is connected to the third outlet port D, the first outlet port C is connected to the second outlet port B, valve 16, valve 17, valve 21, and valve 22 are opened, and valve 15, Valve 18 is closed. In summer conditions, the heat exchanger 5 is an evaporator, and the heat exchanger 7 is an evaporative condenser.

[0022] The whole system in summer can be divided into refrigerant cycle, chilled water cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com