Improved doping method for hole injection and transport layers

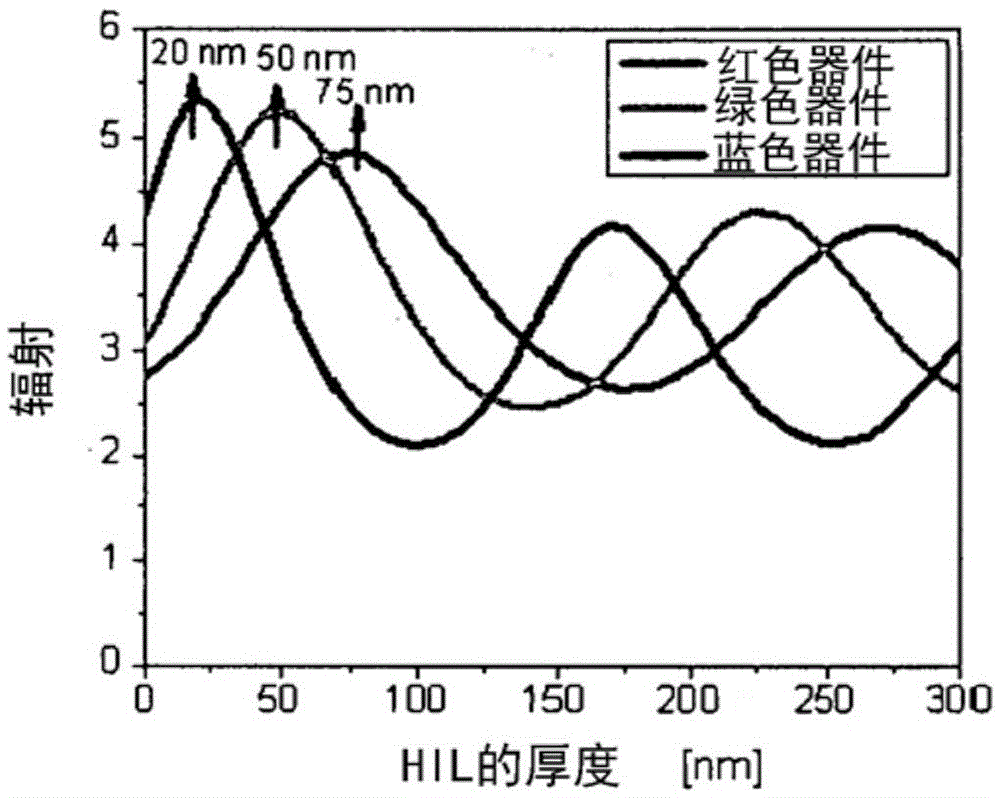

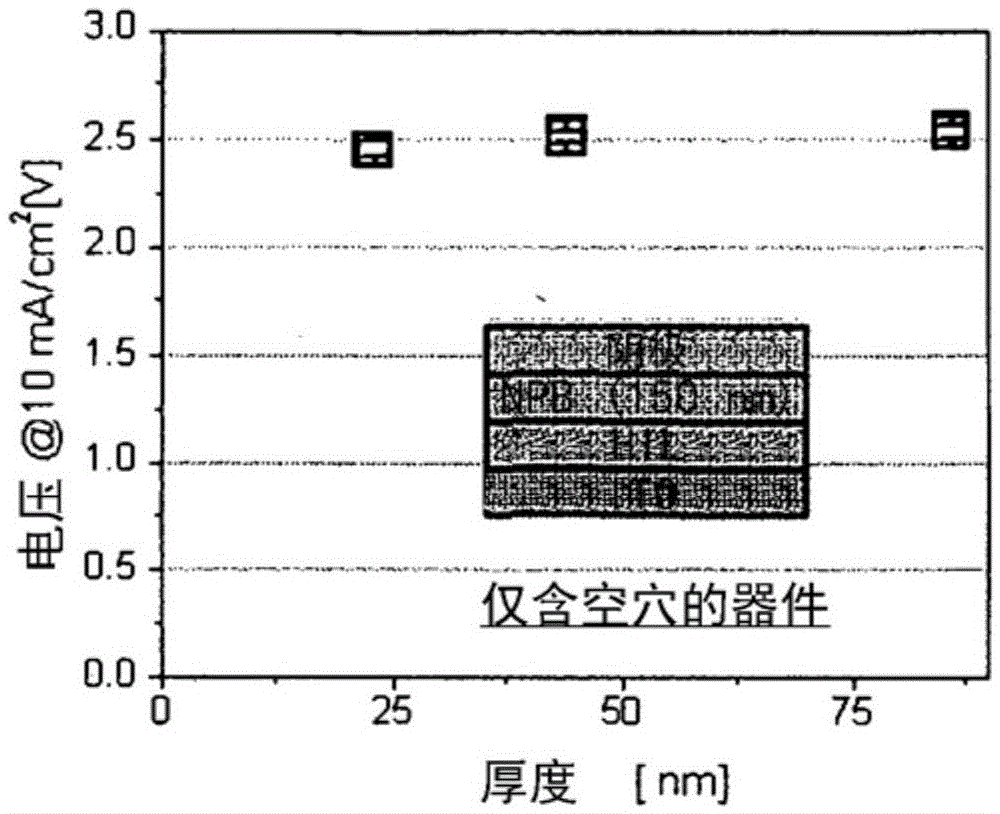

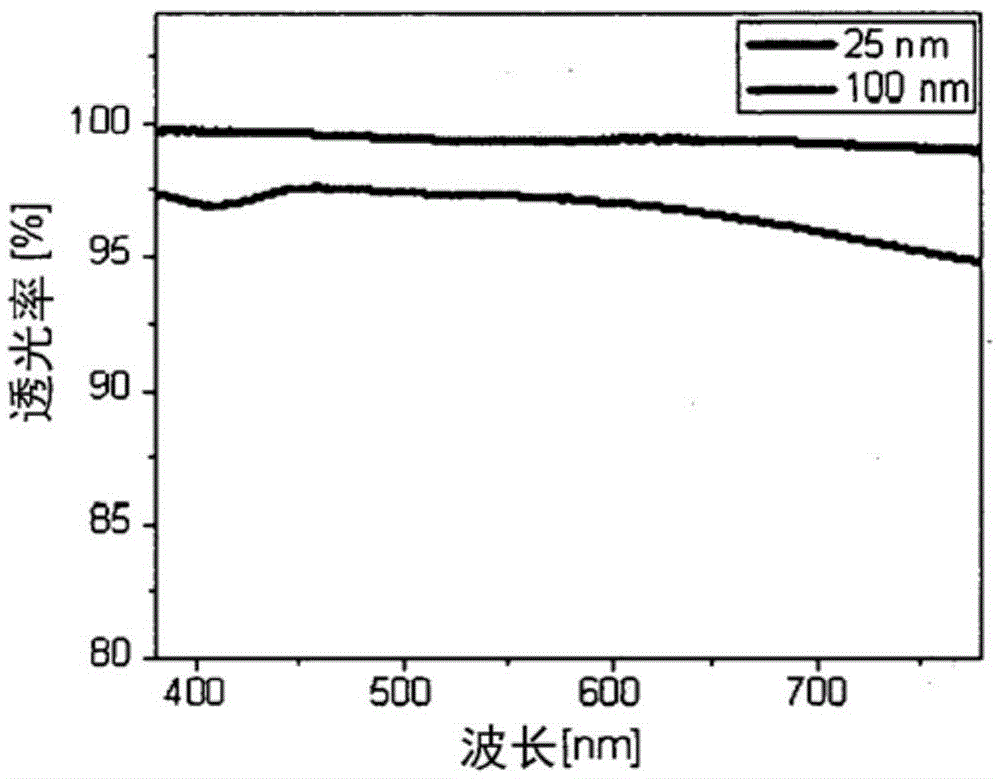

A technology of hole transport and ion doping, which is applied in the field of improved doping for hole injection and transport layers, which can solve problems such as difficult removal and undesired leakage current, and achieve improved current density and luminescence Effects of properties, formulation and construction flexibility, and overall lifespan increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

[0355]

[0356] Poly(3,4-bis(2-(2-poly(3-(3-(2-butoxyethoxy) base) propoxy) thiophene-2,5-diyl).

Embodiment 2

[0358] Synthesis of Butoxyethoxyethoxythiophene:

[0359]

[0360]A 1 L oven-dried 3 NRBF equipped with a condenser, gas inlet and thermometer was charged with 373 g of diethylene glycol butyl ether followed by the addition of 26.41 g of sodium metal. Stir under nitrogen until all sodium is dissolved. To this solution was added 125.5 g of 3-bromothiophene followed by 14.6236 g of Cu(I)I. The mixture was stirred at 100°C for 2.5 hours. Reaction completion was confirmed by GC-MS. 150 g of diethylene glycol butyl ether were vacuum distilled from the RM. The pot residue was diluted with 500 mL of hexane and filtered. The filtrate was washed with 400ml x2 water, followed by 250mL x4 saturated NH 4 Cl solution was washed, and then the organic layer was washed with 300 mL x 3 water. The organic layer was washed with anhydrous MgSO 4 Dried, filtered and concentrated on a rotary evaporator to give 168 g of material. This was vacuum distilled to yield 137.4 g of pure butoxyet...

Embodiment 3

[0370] Synthesis of 3-thienyloxy-3-(1-propanol)

[0371]

[0372] To oven-dried 1 L of 3NRBF equipped with condenser, nitrogen inlet, and thermometer adapter was added 496.7 g of 1,3-propanediol followed by 15.076 g of sodium metal. The reaction mixture was stirred under nitrogen until all sodium was dissolved. At 65° C., 71.79 g of 3-bromothiophene were added, followed by 8.386 g of copper(I) iodide. Stirring was continued at 120°C for 2.5 hours. GC-MS analysis of RM showed 98.8% complete. The reaction mixture was cooled to 35°C, then poured into 1 L of ice water containing 10 g of ammonium chloride. The mixture was neutralized with 1N HCl. Material was extracted from the mixture by washing it three times with 400 mL of MTBE. The combined organic layers were washed four times with 200 mL of saturated ammonium chloride solution, followed by three washes with 200 mL of DI water. The extract was subjected to anhydrous MgSO 4 Drying, filtration and evaporation of the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com