Silage orange meal feed and its preparation process

A preparation process, the technology of orange pulp, applied in the field of pomace fermented feed, silage orange pulp feed and its preparation technology, can solve the problems of orange pulp moisture content, high cost of artificial drying, loss of nutrients, etc., to improve rumen The effect of microbial protein production and feed digestibility, reducing the generation of toxins in the body, and avoiding the loss of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

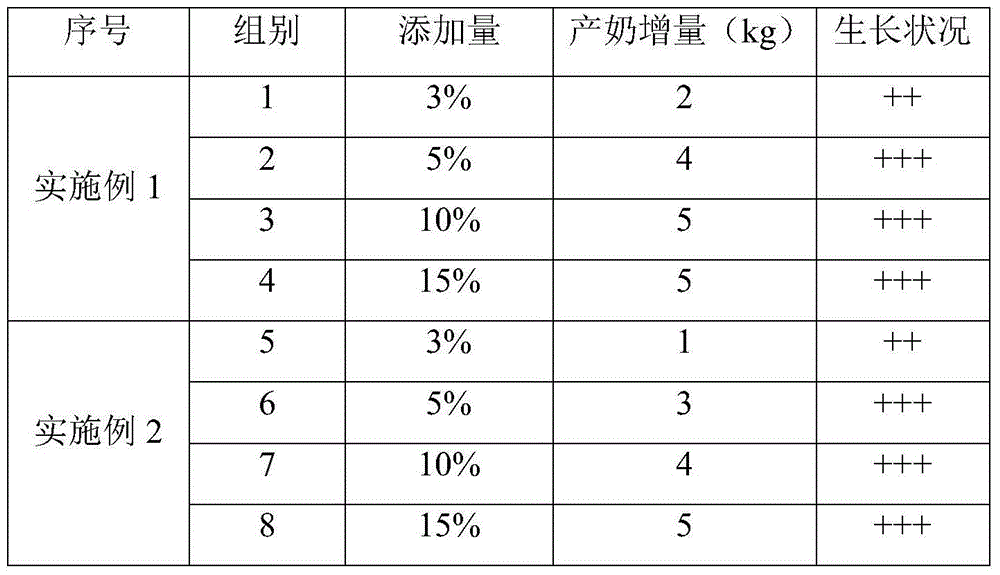

Embodiment 1

[0016] The preparation process of silage tangerine meal feed includes strain propagation and tangerine meal fermentation.

[0017] ① Strain propagation: Lactobacillus acidophilus→solid culture→liquid culture→inoculation expansion culture→cultivation completed, the specific steps are as follows: (a) solid culture: insert the preserved strains on the plate of solid modified MRS medium, Wrap it with plastic wrap, place it in a constant temperature incubator at 37°C and cultivate it for 2 to 3 days; the formula of the improved MRS medium is as follows: by mass fraction, peptone 1% (purchased from Beijing Shuangxuan Microbial Medium Products Factory , enterprise label 02-31A), yeast extract powder 0.5% (purchased from Beijing Shuangxuan Microbial Medium Products Factory, enterprise label 02-12B), beef extract 1% (purchased from Beijing Shuangxuan Microbial Culture Medium Products Factory, enterprise No. 02-05A), glucose 2%, anhydrous sodium acetate 0.3%, diammonium citrate 0.2%, Tw...

Embodiment 2

[0021] Embodiment 2: Different from Embodiment 1, the mass ratio of orange pulp and rice husk powder in step ② is 2.5:1.

Embodiment 3

[0022] Embodiment 3: Different from Embodiment 1, the mass ratio of orange pulp and rice husk powder in step ② is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com