Slurry bed reactor

A technology of reactor and slurry bed, applied in the field of bubbling three-phase slurry bed reactor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

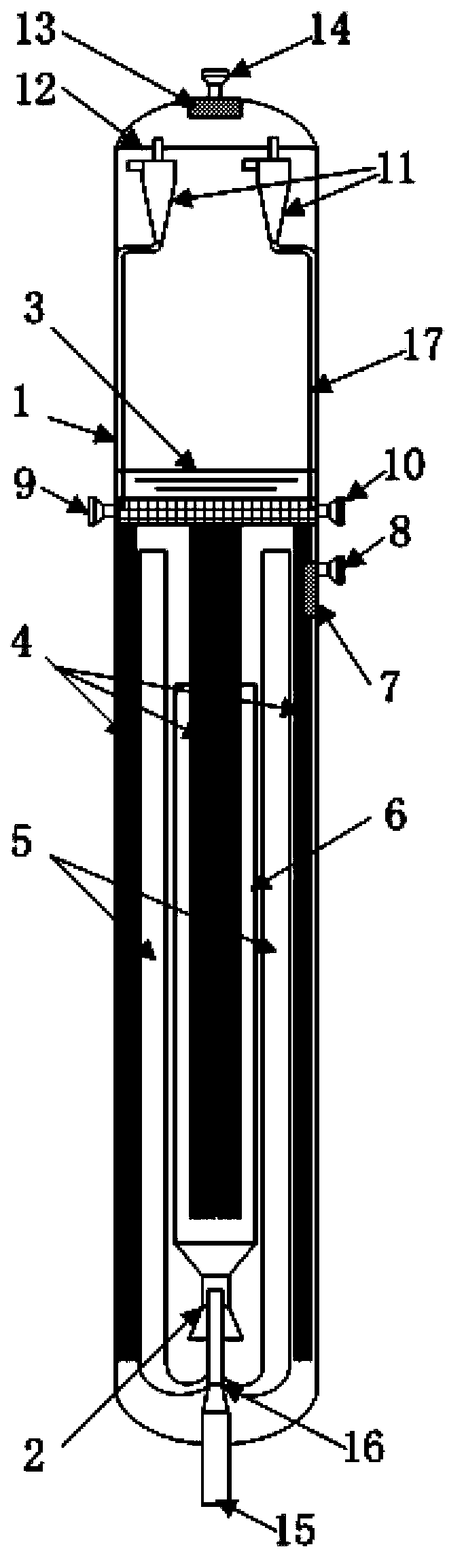

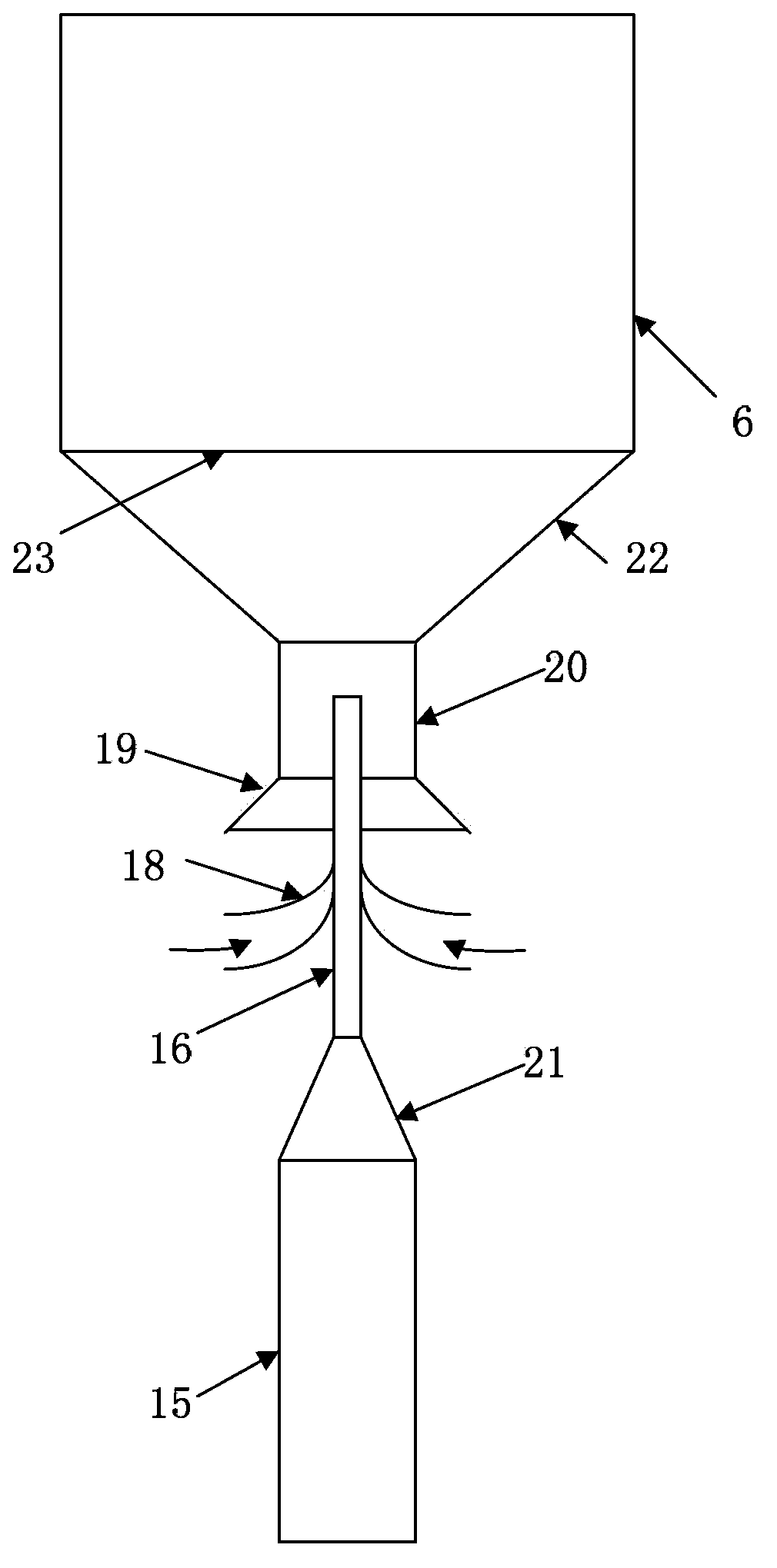

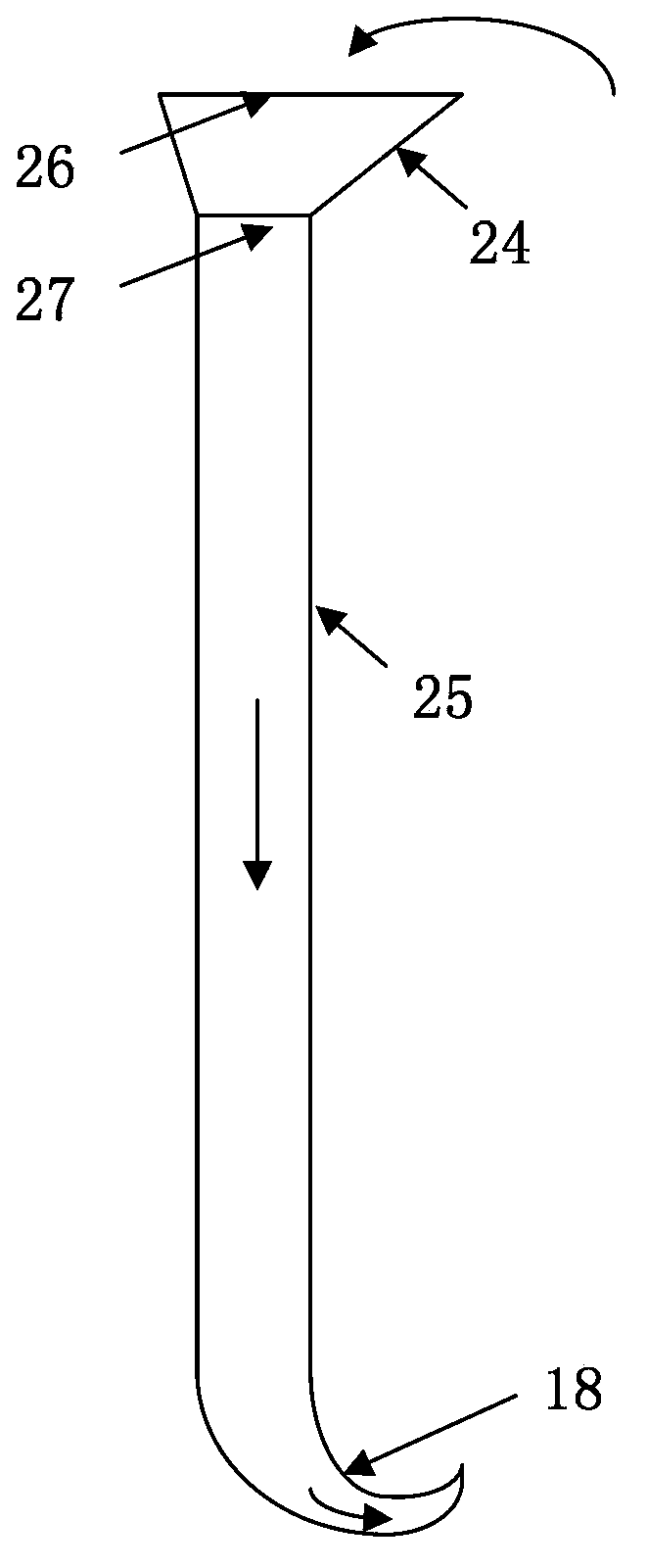

[0090] In this embodiment 1, the mixed gas of hydrogen and carbon monoxide is used as raw material to synthesize hydrocarbon oil in a slurry bed reactor, wherein the synthesized hydrocarbon oil is used as a product in liquid form, and the liquid product is exported from the liquid product outlet after filtering through filter 7 to remove solids 8 elicited. Specifically, this example uses figure 1 For the slurry bed reactor shown, the inner diameter of the slurry bed reactor shell is 1 meter, the longitudinal height of the reactor is 25 meters, and the liquid level in the reactor is 18 meters. The cylinder of the reaction zone is arranged along the central axis of the reactor, with an inner diameter of 0.92 meters and a height of 15 meters. Six settling tubes are evenly arranged around the central axis of the reactor, with an inner diameter of 0.028 meters. The upper feed liquid inlet diameter of the expansion port 24 at the upper end of the settling tube is 0.3 meters, and t...

Embodiment 2

[0095] In Example 2, dimethyl ether was synthesized in a slurry bed reactor using a mixed gas of hydrogen and carbon monoxide as a raw material. The reactor design is basically the same as the reactor in Example 1, the only difference is that since the product DME is in gaseous form, it is drawn from the top outlet together with the tail gas, so the reactor in Example 2 does not need filter 7 and liquid phase outlet 8 .

[0096] The pressure in the reactor was 4 MPa, and the temperature of the reaction system was maintained at 270°C by using water from which oxygen and salt had been removed as a condensing agent and passing it through a heat exchange tube bundle. The raw gas used is H 2 / CO volume ratio of 1:1 syngas. Catalyst is the bifunctional catalyst that industrial synthesis methanol catalyst C301 and aluminum oxide dehydration catalyst form, and these catalysts are suspended in solvent liquid paraffin liquid, form the slurry that solid weight content is 15%, and descr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com