Method for preparing photocatalyst for porous pucherite nanosheet modified by ferric oxide

A technology of bismuth vanadate and nanosheets is applied in the field of inorganic nanophotocatalytic materials, which can solve the problems of low catalytic activity and achieve the effects of high photocatalytic activity, high efficiency and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Porous BiVO in this embodiment 4 The synthesis process of nanosheets is as follows:

[0044] Weigh 1mmol of bismuth nitrate, dissolve it in 20mL of ethylene glycol, stir to dissolve it, and mark it as solution A; take another 4.25mmol of sodium hydroxide and 2mmol of terephthalic acid and dissolve it in 10mL of water, stir to dissolve it, and mark it as Solution B. Next, add solution B to solution A and let it stand at about 20 degrees Celsius for 4 hours. Add the above-mentioned solution and 0.0732g of sodium metavanadate into the polytetrafluoroethylene liner of the high-pressure reaction kettle, and after stirring the mixed solution for several times, put the reaction kettle into an electric heating constant-temperature blast drying oven after being sealed, and dry it at 180 ℃ for constant temperature reaction for 10 hours. After the reaction is completed and naturally cooled to room temperature, the product is taken out for centrifugation, and after drying, solid...

Embodiment 2

[0047] This embodiment contains Fe 2 o 3 The molar ratio is 2.5% Fe 2 o 3 / BiVO 4 The preparation method of porous nanosheet is as follows:

[0048] Add 0.4mmol of porous bismuth vanadate nanosheets synthesized above, 1mmol of sodium hydroxide, 40mL of water and 0.02mmol of ferric nitrate into the autoclave. In the oven, react at a constant temperature of 160°C for 12h. After the reaction was completed and naturally cooled to room temperature, the product was taken out for centrifugation, and washed several times with absolute ethanol and high-purity water respectively. The product is finally placed in a vacuum drying oven and dried at 60°C for 4 hours to obtain Fe with a molar ratio of iron oxide of 2.5%. 2 o 3 / BiVO 4 porous nanosheets.

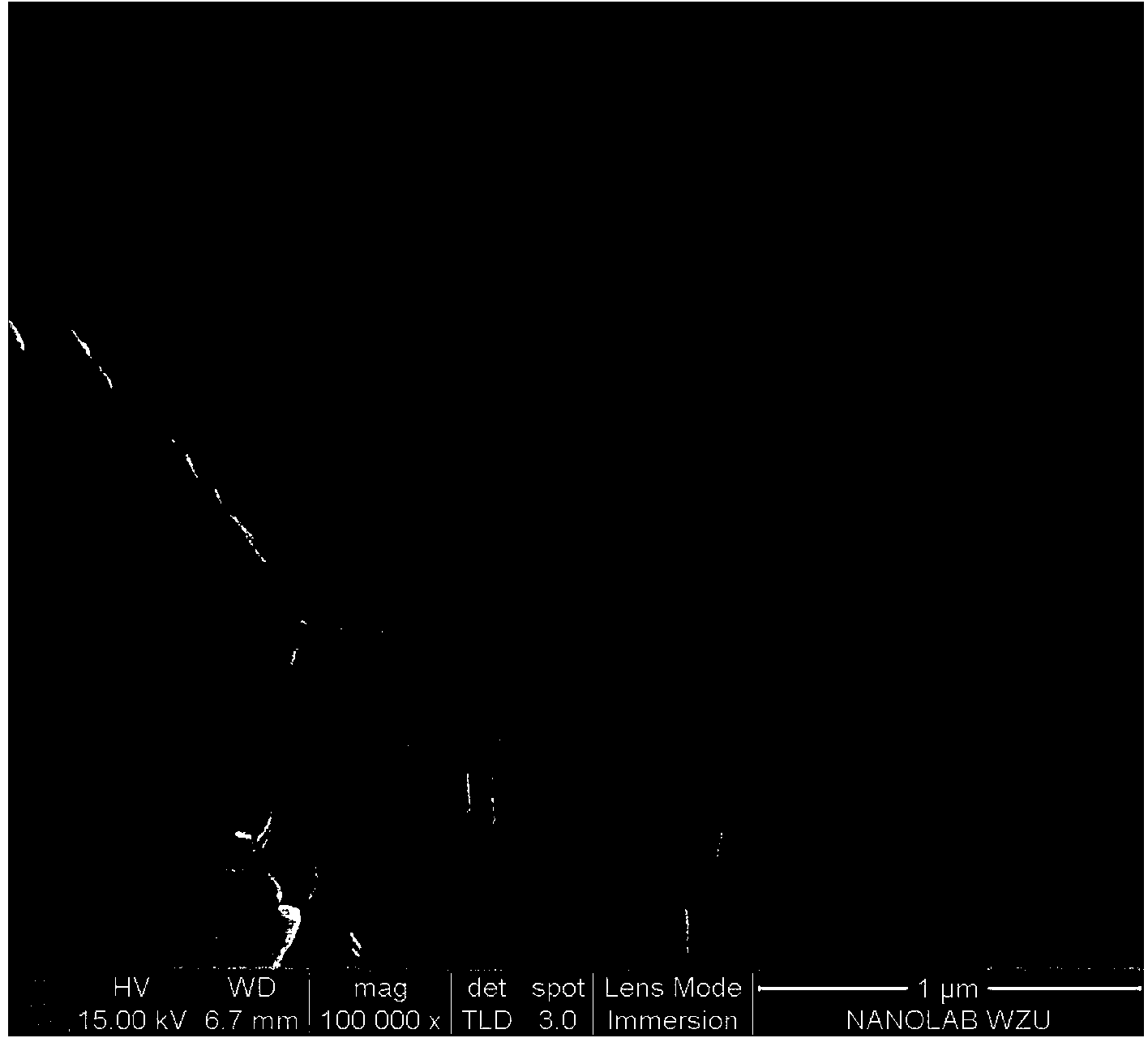

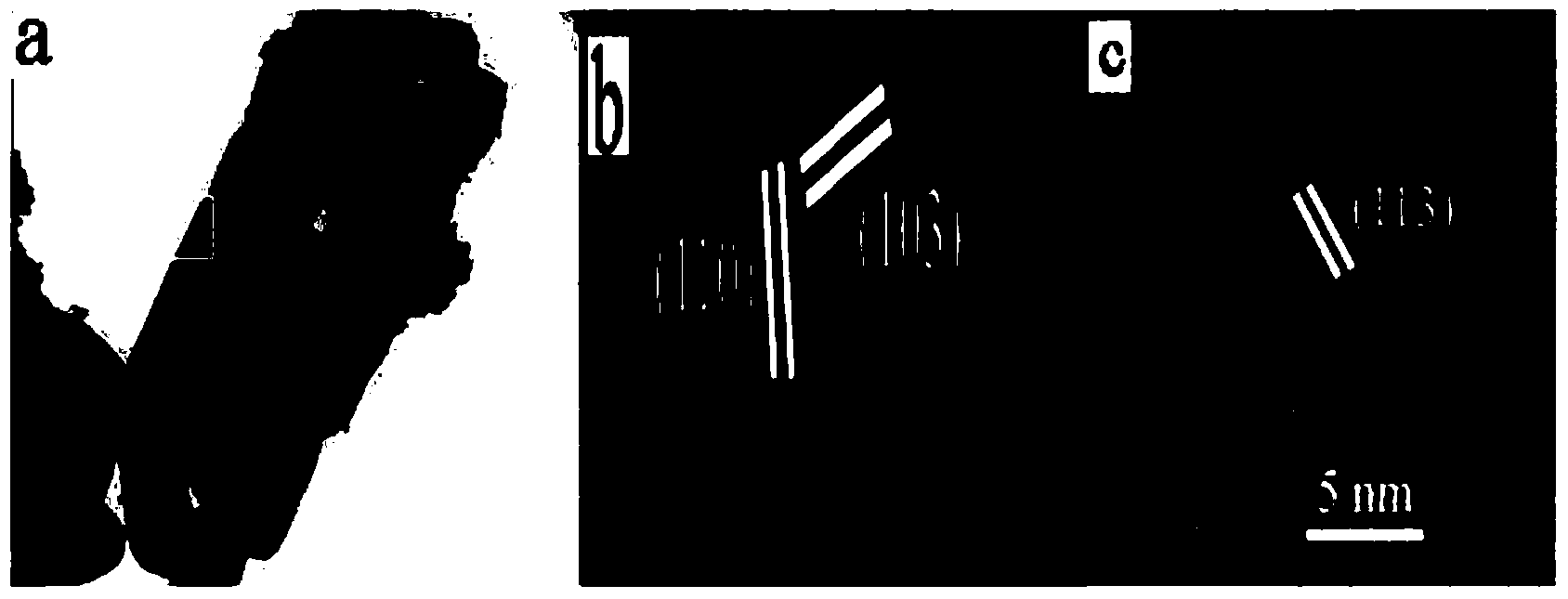

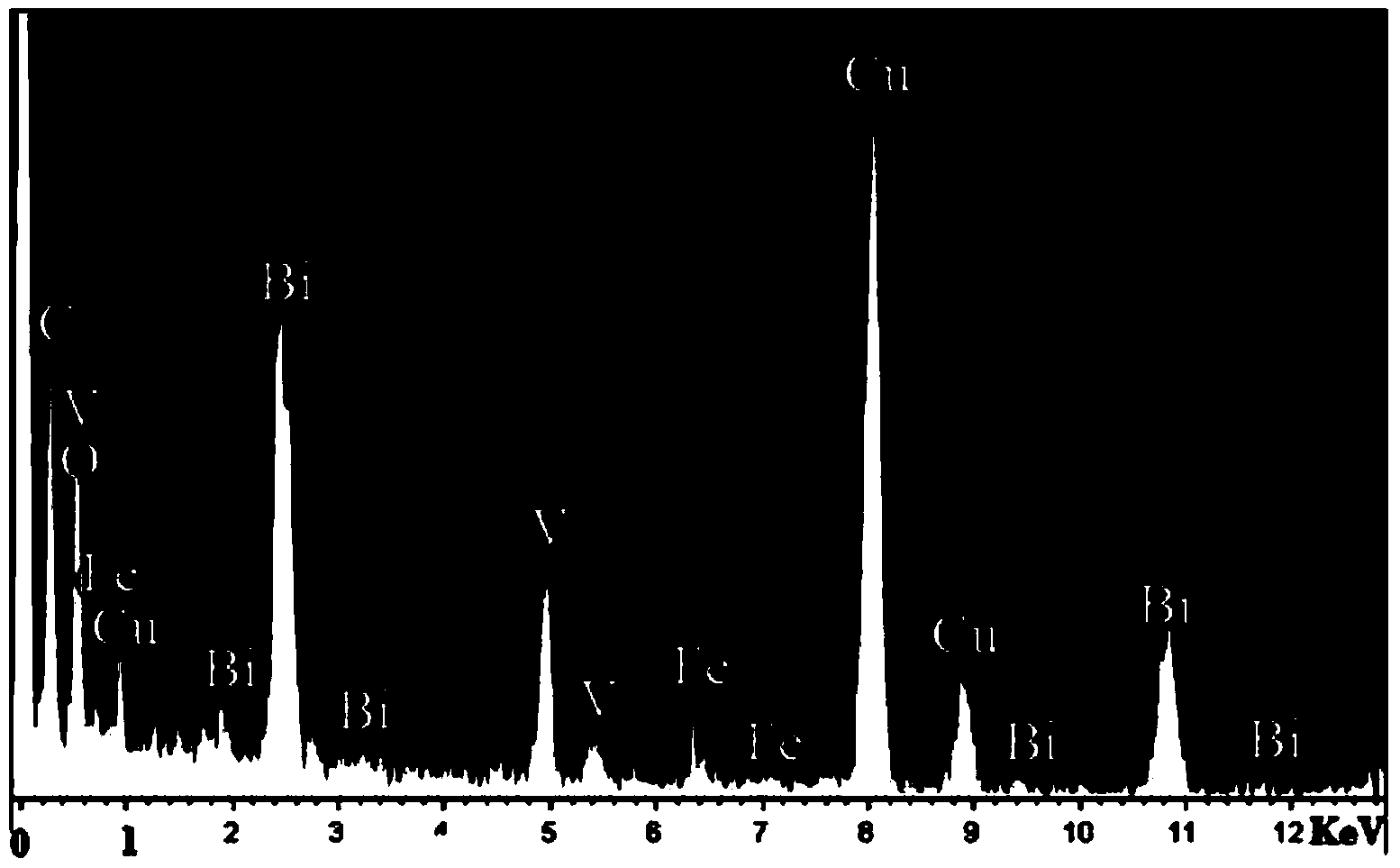

[0049] Depend on figure 2 a, transmission electron microscope observation shows that Fe 2 o 3 / BiVO 4 Still maintain a porous nanosheet structure. figure 2 High-resolution analysis of the rectangular area in a shows that the...

Embodiment 3

[0051] Contains different molar proportions of Fe 2 o 3 Fe 2 o 3 / BiVO 4 The preparation method of porous nanosheet composite photocatalyst is as follows:

[0052] The difference between this embodiment and the second embodiment is that different proportions of ferric nitrate (0.008-0.04 mmol) are respectively added to the reaction system, and other operating procedures remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com