Method for comprehensively processing tremolite into flavor powder and polymerization plates

A technology for comprehensive processing and polymerizing plates, which is applied in the field of artificial synthetic stone and non-metallic materials for building decoration materials, can solve environmental pollution, does not involve the art of forming microcrystalline sheet forming technology of tailings recycling and utilization of blocks, and is not suitable for scale. Industrial production and other problems, to achieve the effect of reducing the enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

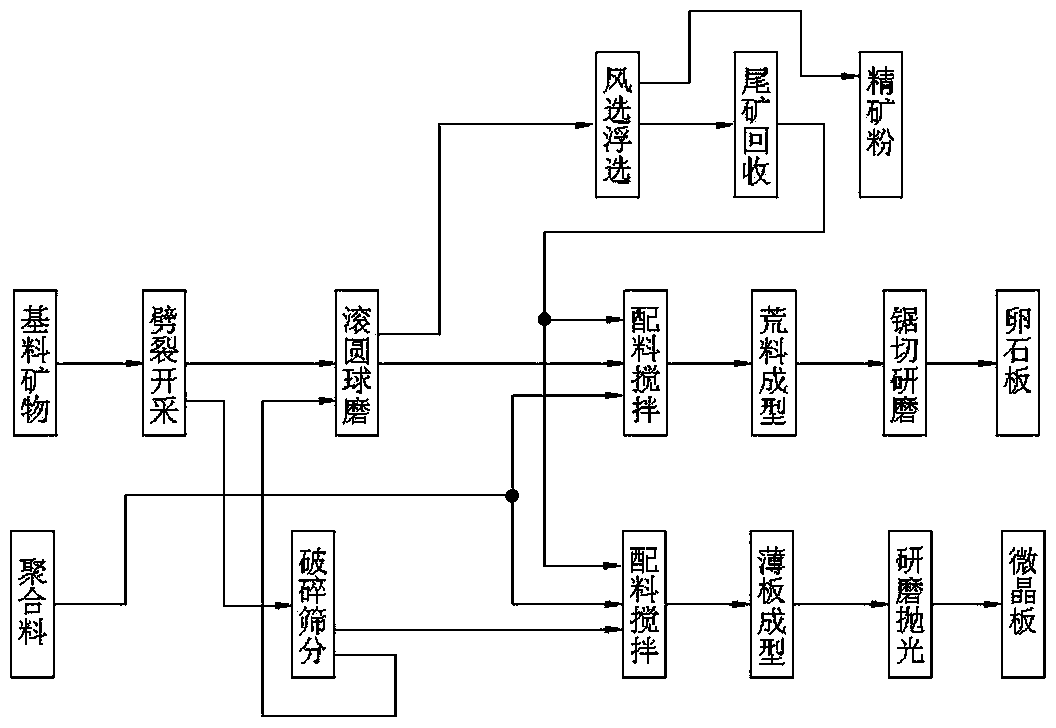

Image

Examples

Embodiment 1

[0029] Using tremolite and actinolite from a tremolite mine in Shanxi Province as base minerals, comprehensive processing of 600-1250 mesh tremolite fine powder and pebble (aggregate) board is carried out. The content of needle-columnar tremolite in this mine is about 65%, the content of granular calcite is about 35%, the size of fibrous crystals is 0.001X0.1mm, the size of needle-like crystals is 0.05x0.5mm, and calcite is filled in the tremolite distributed in a shape. Between crystals, generally 0.1-0.5mm. SiO of the mine 2 42.78 and Ca0 is 23.92, low in silicon and high in calcium, so that when it simply processes fine powder, it will cause more than half of the tailings and affect the environment, and it will also cause the problem of high production costs. It is the only way for its sustainable development to adopt the comprehensive processing method of fine powder and aggregate plate in parallel.

[0030] The specific process of pebble (polymer) board is:

[0031] Sp...

Embodiment 2

[0039] Diopside, skarn and stromatolite minerals from the diopside mine are used for comprehensive processing of three products: fine powder, pebble board and microcrystalline board. The purer diopside is white and light green, and the calcium ferropyroxene and neonite are dark green respectively, and the foreign iron oxide precipitation is dotted with red. The intermediate members of CaMg-CaFe include subdiopside and iron subdiopside, and those containing Cr are called chromium diopside. During its ball milling process, its hardness of 5.5-6.5 and 3.27-3.38g / cm 3 The characteristics of the specific gravity make it accompanied by the mixing and grinding of the particles, and the observation that the particles approach each other along the extension direction by adsorption will naturally appear, especially for equiaxed quartz particles in vibration molding, it is easier to fill Voids composed of diopside needle-like and columnar minerals. The beige, brown and texture of strom...

Embodiment 3

[0048] Tremolite marble, stromatolites and actinolite are used as the base material to carry out comprehensive processing of 200-800 mesh tremolite powder, stromatolites powder, pebble aggregate board and inorganic microcrystalline board. The stromatolite fine powder has strong environmental purification performance and can be used for building decoration materials and coatings. The specific process of pebble aggregate board is as follows:

[0049] The processes of splitting mining, ball milling, crushing and screening, and tailings recovery are the same as in Example 1;

[0050] Wherein, air selection flotation process adopts dry process and is the same as embodiment 2;

[0051] The batching mixing and block molding process is to mix the three base material pebbles according to the mass ratio of 1:1:1, and use the zigzag linkage type crushed stone polymerization molding device to mix the pebbles separately; the organic high polymer is made of unsaturated resin, The curing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com