Hydrophobically-modified polyethyleneimine foaming agent capable of releasing carbon dioxide, and application thereof

A polyethyleneimine and carbon dioxide technology, applied in the preparation of polyurethane foam materials, hydrophobically modified polyethyleneimine foaming agents and their preparation fields, can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-16

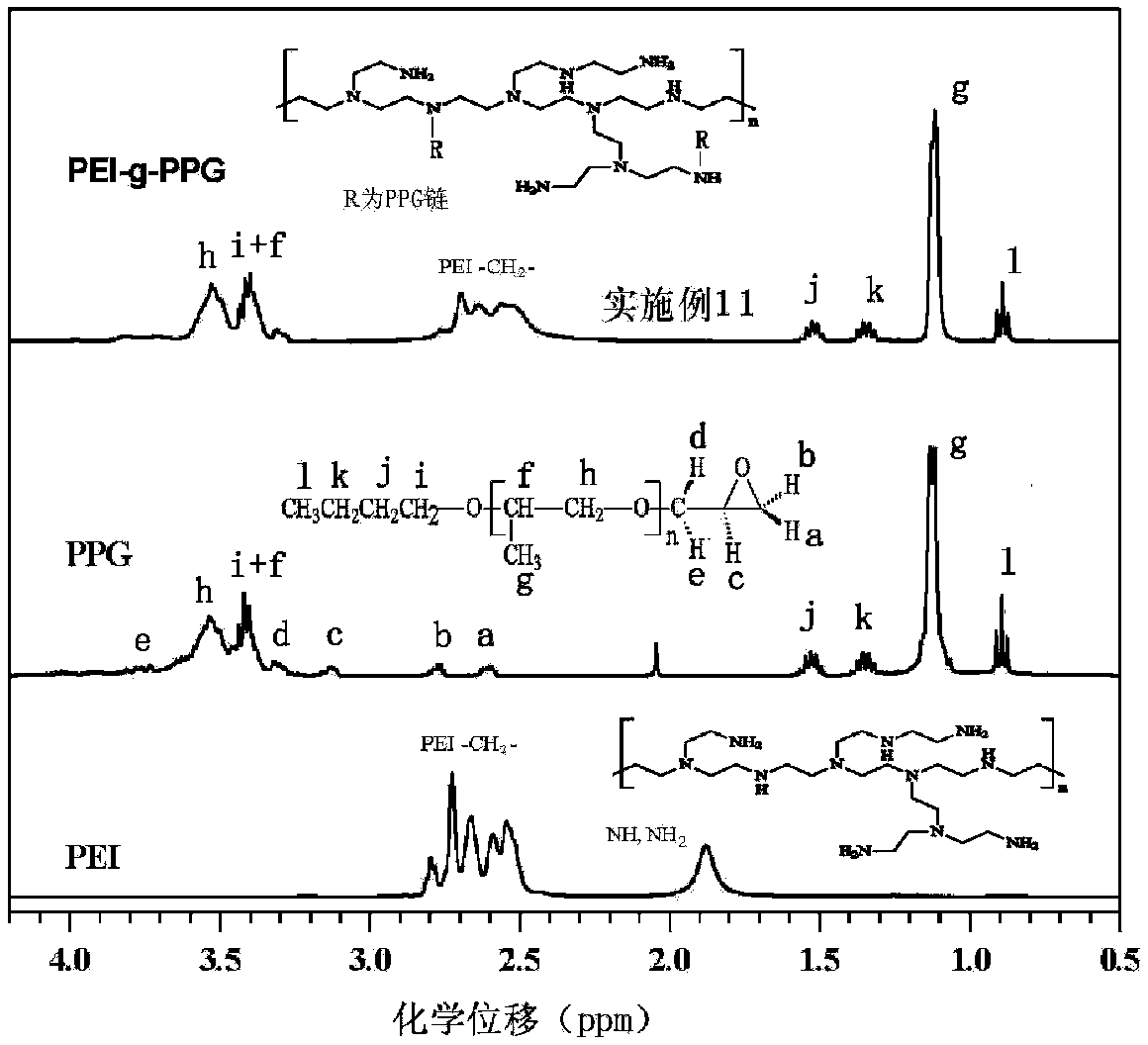

[0072] This group is polyethylene with glycidyl ether compounds, that is, glycidyl ether compounds hydrophobically modified by the reaction of glycidyl ether groups (ie, epoxy groups) on it with amine groups in polyethyleneimine. Examples of imines.

[0073] Table 1

[0074]

[0075] The above-mentioned glycidyl ether compound hydrophobically modified polyethyleneimine is prepared by the following method: polyethyleneimine (PEI) is added in the reactor, and ethanol is added in the reactor, and the polyethyleneimine is mixed under stirring conditions. Dissolve the amine completely, then add glycidyl ether hydrophobic compound to the dissolved polyethyleneimine, stir and react at 25-80°C for 0.5-3 days, then remove ethanol by rotary evaporation; first add 20 ~40 parts by volume of petroleum ether to dissolve unreacted glycidyl ether hydrophobic compounds in the product, and then add 1 / 3 of distilled water based on petroleum ether to separate out glycidyl ether compounds. Am...

Embodiment 17-27

[0078] This group is an example of hydrophobically modified polyethyleneimine produced by the reaction of alkylcarboxylic acid hydrophobic compound and amine group in polyethyleneimine.

[0079] The polyethyleneimine hydrophobically modified by the alkyl carboxylic acid compound is prepared by the following method: adding polyethylene imine (PEI), alkyl carboxylic acid compound and catalyst into the reactor, and adding Chloroform until the above substances are completely dissolved, then stir and react under reflux for 10 to 15 hours; extract the reactant with saturated saline for at least three times, take the chloroform layer and remove the chloroform by rotary evaporation and then dry to constant weight. The recipes of the raw materials used are shown in Table 2. It can be seen from Table 2 that 5.2-34.5 mol% of N atoms in PEI chains are grafted with hydrophobic chains.

[0080] Table 2

[0081]

Embodiment 28-37

[0083] This group is an example of polyethyleneimine hydrophobically modified by the halogenated alkane compound reacted with the amine group in polyethyleneimine.

[0084] table 3

[0085]

[0086] The above-mentioned halogenated alkane compound hydrophobically modified polyethyleneimine is prepared by the following method: polyethyleneimine and halogenated alkane compound are added in chloroform, the two are completely dissolved, room temperature (to iodoalkane) or reflux temperature (for the rest of the halogenated alkanes) under stirring for a certain period of time (see Table 3); dissolve 4 parts by mass of NaOH in 1 / 2 volume of water based on chloroform, add the NaOH solution to the reaction mixture and wash for 30 minutes, remove the water layer Add water equal to the volume of chloroform and wash twice, each 30 minutes, remove the water layer; finally remove the chloroform by rotary evaporation and dry to constant weight. It can be seen from Table 3 that 5-40.4 mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com