A kind of preparation method of imitation mussel glue that can be bonded on wet surface and solidified under water

A technology of surface bonding and underwater curing, applied in the directions of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of low bonding strength of bionic mussel glue, and achieve a simple and efficient synthesis method. Compatibility and initial viscosity, the effect of breaking through technical bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

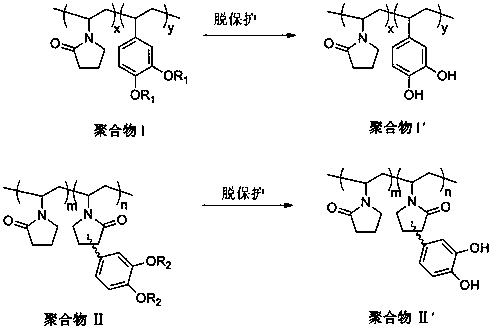

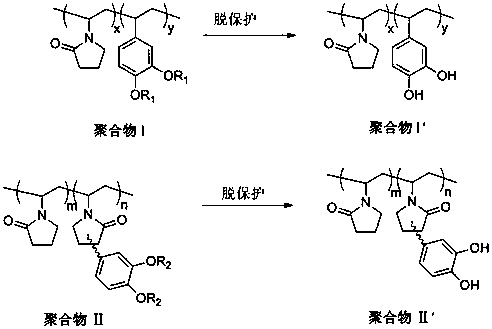

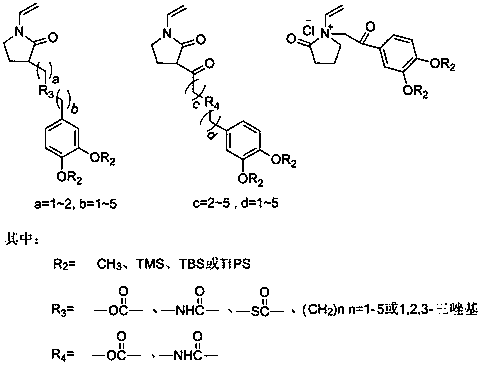

Method used

Image

Examples

Embodiment 1

[0020]

[0021] Add N-vinylpyrrolidone (NVP) (2.22g0.02mol), catechol derivative MSt (0.10g0.6mmol) and THF (5mL) into a 50ml reaction flask, add AIBN (0.04mmol6.6mg), and argon Air for 30min and react at 60℃ for 24h. Lower to room temperature, precipitate in n-hexane (100 mL), dissolve and precipitate the precipitate three times repeatedly, and dry to obtain copolymer I m (2.1g) (M n =51KDaM w / M n =1.7).

[0022] Add the prepared copolymer I to a 50ml reaction flask m , Tetrahydrofuran (6mL), boron tribromide (0.7g2.8mmol), reacted for 10 hours under the protection of argon. The concentrated reaction solution was dropped into n-hexane (50 mL) under stirring, the precipitate was repeatedly dissolved and precipitated three times, and dried to obtain polymer I' m (1.7g). Polymer I′ m Dissolve in 2mL of absolute ethanol, add 0.03g of ferric chloride, and stir evenly to obtain biomimetic mussel glue.

Embodiment 2

[0024]

[0025] Add N-vinylpyrrolidone (NVP) (2.22g0.02mol), catechol derivative BSt (3.64g0.1mol) and THF (10mL) into a 50ml reaction flask, add AIBN (0.4mmol66mg), and argon for 30min , React at 60℃ for 48h. Cool to room temperature, precipitate in n-hexane (100 mL), dissolve and precipitate the precipitate three times repeatedly, and dry to obtain copolymer I B (4.1g) (M n =4.9KDaM w / M n =2.1).

[0026] Add the prepared copolymer I to a 50ml reaction flask B , Tetrahydrofuran (15mL), concentrated hydrochloric acid (2mL), react under argon protection for 10 hours. The concentrated reaction solution was dropped into n-hexane (50 mL) under stirring, the precipitate was repeatedly dissolved and precipitated three times, and dried to obtain polymer I' B (3.1g). Polymer I′ B Dissolve in 35mL of absolute ethanol, add 0.57g of ferric chloride, and stir evenly to obtain biomimetic mussel glue (when the substrate is aluminum, the wet surface is bonded under water and the bonding stren...

Embodiment 3

[0028]

[0029] Add N-vinylpyrrolidone (NVP) (2.22g0.02mol), catechol derivative ENVP (0.32g0.6mmol) and THF (10mL) into a 50ml reaction flask, add AIBN (0.5mmol82mg), and argon for 30min , React at 60℃ for 48h. Reduce to room temperature, precipitate in n-hexane (100 mL), dissolve and precipitate the precipitate three times repeatedly, and dry to obtain copolymer II E (2.0g) (M n =5.1KDaM w / M n =1.8).

[0030] Add the prepared copolymer Ⅱ into a 50ml reaction flask E , Tetrahydrofuran (15mL), concentrated hydrochloric acid (2mL), reacted for 10 hours under argon protection. The concentrated reaction solution was dropped into n-hexane (50 mL) under stirring, the precipitate was repeatedly dissolved and precipitated three times, and dried to obtain polymer II' E (1.4g). Polymer Ⅱ' E Dissolve in 10 mL of absolute ethanol, add ferric chloride at 1 / 3 (mole fraction) of the catechol group content in the polymer, stir evenly to obtain the bionic mussel glue (when the substrate is alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com