Method for finishing fabric through plant essential oil thermosensitive liposomes

A heat-sensitive liposome and plant essential oil technology, applied in the fields of medical materials, textiles and clothing, can solve problems such as poor safety and chemical stability, increased manufacturing costs of antibacterial agents, unfavorable development of antibacterial finishing, etc., achieving obvious cooling effect, Improve antibacterial efficiency and broad-spectrum antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

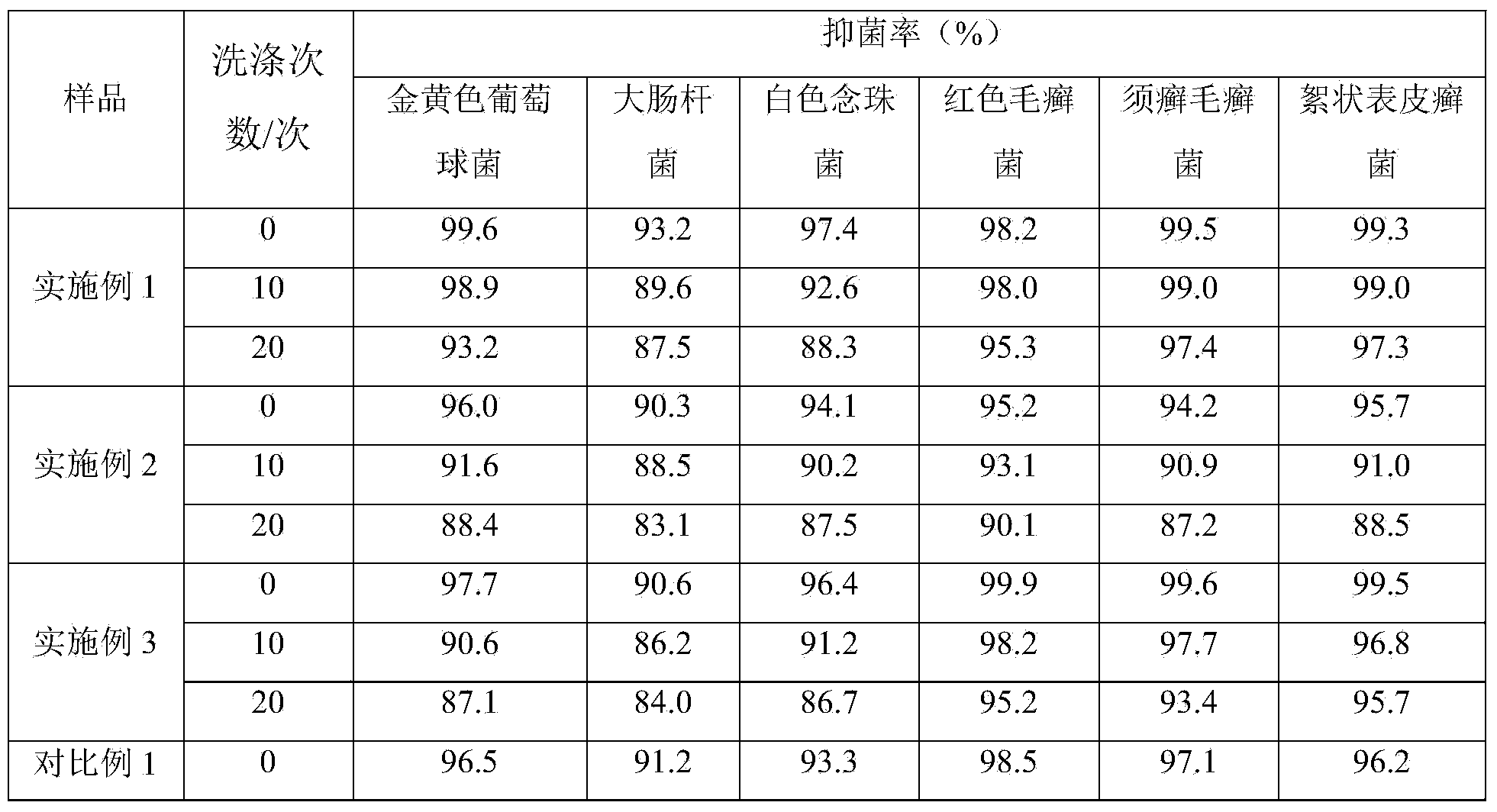

Embodiment 1

[0038] A method for finishing fabrics with plant essential oil thermosensitive liposomes, comprising the steps of:

[0039] (1) Mix tea tree essential oil, menthol and mugwort essential oil at a mass ratio of 1:1:1 at 0°C with a stirring speed of 30 rpm to obtain a natural aromatic antibacterial agent.

[0040] (2) Prepare phosphate buffer solution: sodium chloride 8g / L, potassium chloride 0.2g / L, disodium hydrogen phosphate 1.44g / L, dipotassium hydrogen phosphate 0.24g / L, adjust pH to 6.5 with hydrochloric acid, add The final concentration was 6% v / v Tween 80. Dissolve the natural fragrance antibacterial agent in the above-mentioned phosphate buffer solution, so that the concentration of the natural fragrance antibacterial agent is 15g / L.

[0041] (3) Soybean lecithin, 1-myristoyl-2-stearoyl lecithin, dipalmitoylphosphatidylglycerol sodium salt, dimyristoylphosphatidylethanolamine, dipalmitoylphosphatidylserine sodium salt and dimeat The sodium myristoyl phosphatidic acid i...

Embodiment 2

[0046] A method for finishing fabrics with plant essential oil thermosensitive liposomes, comprising the steps of:

[0047] (1) Mix tea tree essential oil, menthol and mugwort essential oil at a mass ratio of 3.5:1:3 at 4°C with a stirring speed of 120 rpm to obtain a natural aromatic antibacterial agent;

[0048] (2) Prepare phosphate buffer solution: sodium chloride 8g / L, potassium chloride 0.2g / L, disodium hydrogen phosphate 1.44g / L, dipotassium hydrogen phosphate 0.24g / L, adjust pH to 6.5 with hydrochloric acid, add The final concentration was 6% v / v Tween 80. Dissolve the natural fragrance antibacterial agent in the above-mentioned phosphate buffer solution, so that the concentration of the natural fragrance antibacterial agent is 30g / L.

[0049] (3) Egg yolk lecithin, dipalmitoyl lecithin, distearoylphosphatidylglycerol sodium salt, dipalmitoylphosphatidylethanolamine, distearoylphosphatidylserine sodium salt and dipalmitoylphosphatidic acid sodium salt as substances T...

Embodiment 3

[0054] A method for finishing fabrics with plant essential oil thermosensitive liposomes, comprising the steps of:

[0055] (1) Mix and stir tea tree essential oil, menthol and mugwort essential oil at a mass ratio of 2:1:2 at 2°C at a stirring speed of 60 rpm to obtain a natural aromatic antibacterial agent.

[0056] (2) Prepare phosphate buffer solution: sodium chloride 8g / L, potassium chloride 0.2g / L, disodium hydrogen phosphate 1.44g / L, dipotassium hydrogen phosphate 0.24g / L, adjust pH to 6.5 with hydrochloric acid, add The final concentration was 6% v / v Tween 80. Dissolve the natural fragrance antibacterial agent in the above-mentioned phosphate buffer solution, so that the concentration of the natural fragrance antibacterial agent is 20g / L.

[0057] (3) Egg yolk lecithin, distearoyl lecithin, distearoylphosphatidylglycerol sodium salt, dipalmitoylphosphatidylethanolamine, distearoylphosphatidylserine sodium salt and dimyristoylphosphatidic acid sodium salt The ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com