A kind of preparation method of nickel-based catalyst

A nickel-based catalyst, nickel-aluminum alloy technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve carbon deposition, low-temperature catalytic activity, poor selectivity It can solve the problem of low reactivity and achieve the effect of high reactivity, uniform mixing of components and good H2 selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of a nickel-based catalyst, the composition of which is designed as:

[0025] System 1: Ni 3 Al, 1mol; tin nitrate, 0.05mol;

[0026] System 2: Ni 3 al 2 , 1mol; platinum nitrate, 0.05mol;

[0027] System 3: NiAl, 1mol; Palladium acetate, 0.05mol;

[0028] System 4: Ni 3 al 5 , 1mol; rhodium nitrate, 0.05mol;

[0029] The specific steps are: 1), preparing single-phase nickel-aluminum alloy sheet by smelting method; and preparing nickel-aluminum alloy sheet by cold rolling and stretching; the thickness of the alloy sheet is 5um; 2), the nickel-aluminum alloy sheet of step (1) Put into 40wt% NaOH solution and treat for 10h; the reaction temperature is 120°C, the reaction product is centrifuged and washed 3 times with distilled water; 3), the product obtained in step (2) is immersed in the doping salt solution, and vacuum-dried at 100°C for 5h; 4) , sintering the product obtained in step (3) in high-temperature air, the sintering temperature is...

Embodiment 2

[0032] A kind of preparation method of nickel-based catalyst, catalyst composition is designed as:

[0033] System 5: Ni 3 Al, 1mol; tin nitrate, 0.1mol;

[0034] System 6: Ni 3 Al, 1mol; tin nitrate, 0.15mol;

[0035] System 7: Ni 3 Al, 1mol; tin nitrate, 0.2mol;

[0036] Its concrete steps are: 1), adopt smelting method to prepare single-phase nickel-aluminum alloy; 3 Al alloy sheet; the thickness of the alloy sheet is 5um; 2), put the nickel-aluminum alloy sheet in step (1) into 30wt% KOH solution for 8h; the reaction temperature is 150°C, the reaction product is centrifuged and washed 3 times with distilled water; 3), Immerse the product obtained in step (2) into the doped tin nitrate solution, and dry it in vacuum at 100°C for 5 hours; 4), sinter the product obtained in step (3) in high-temperature air, the sintering temperature is 1100°C, and the sintering time is 5h; 5 ), reducing the product obtained in step (4) at high temperature in a hydrogen atmosphere, the r...

Embodiment 3

[0039] With embodiment 1 operation, catalyst composition is designed as:

[0040]System 5: NiAl, 1mol; rhodium nitrate, 0.1mol;

[0041] System 6: NiAl, 1mol; Palladium nitrate, 0.15mol;

[0042] System 7: NiAl, 1mol; tin nitrate, 0.2mol;

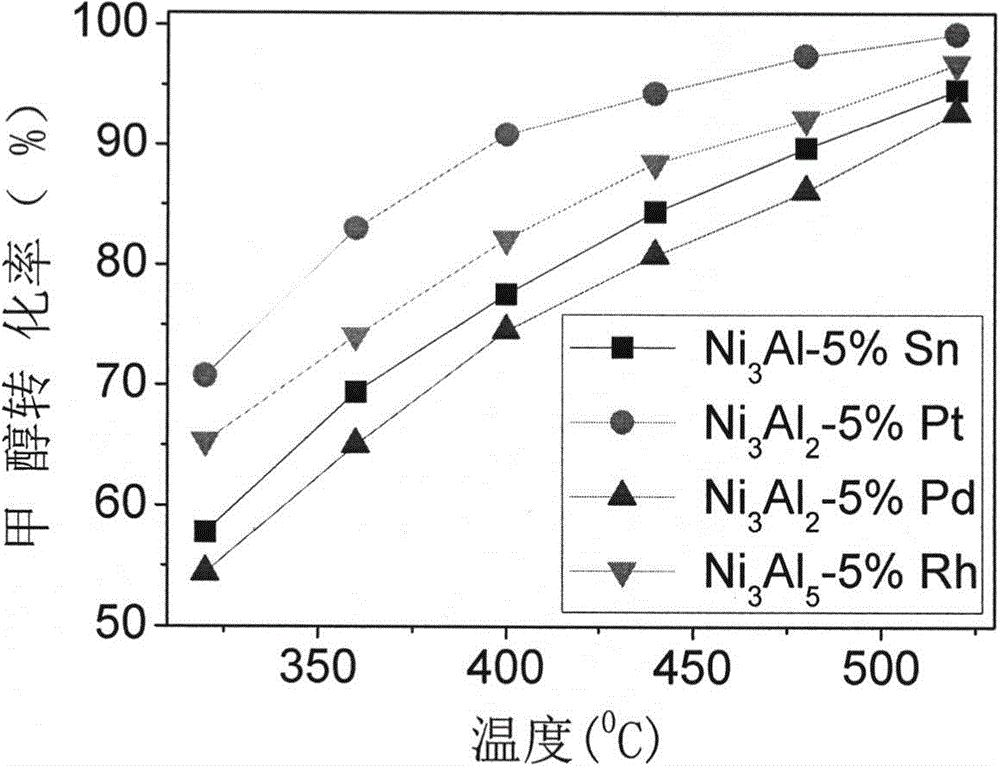

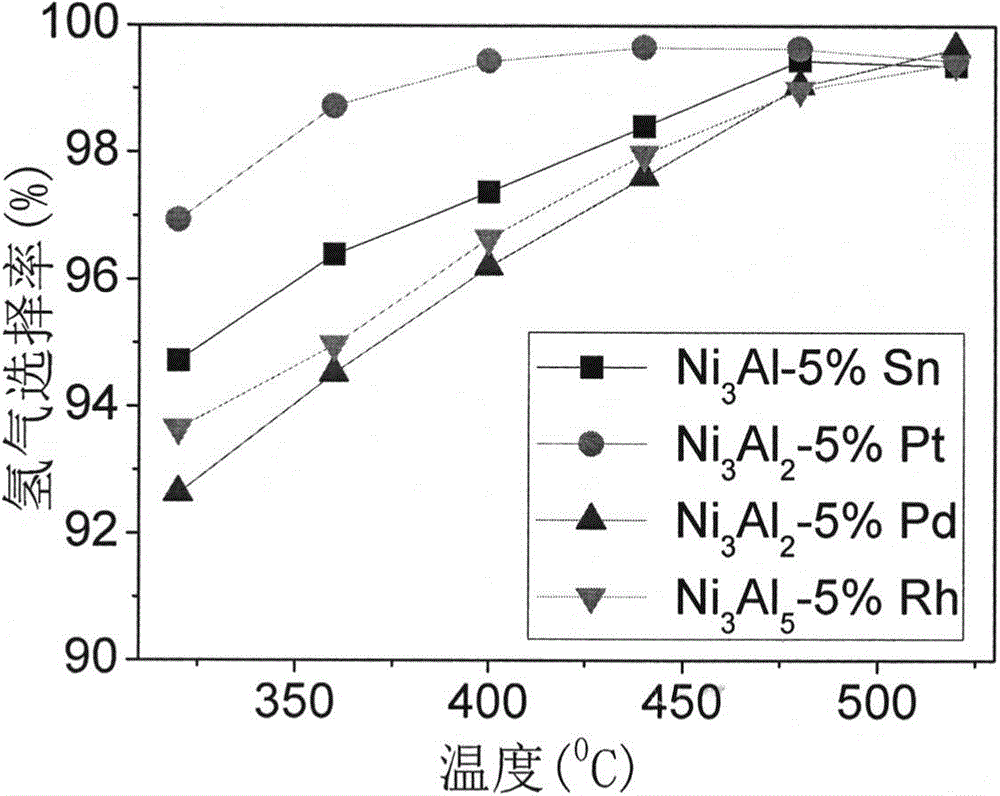

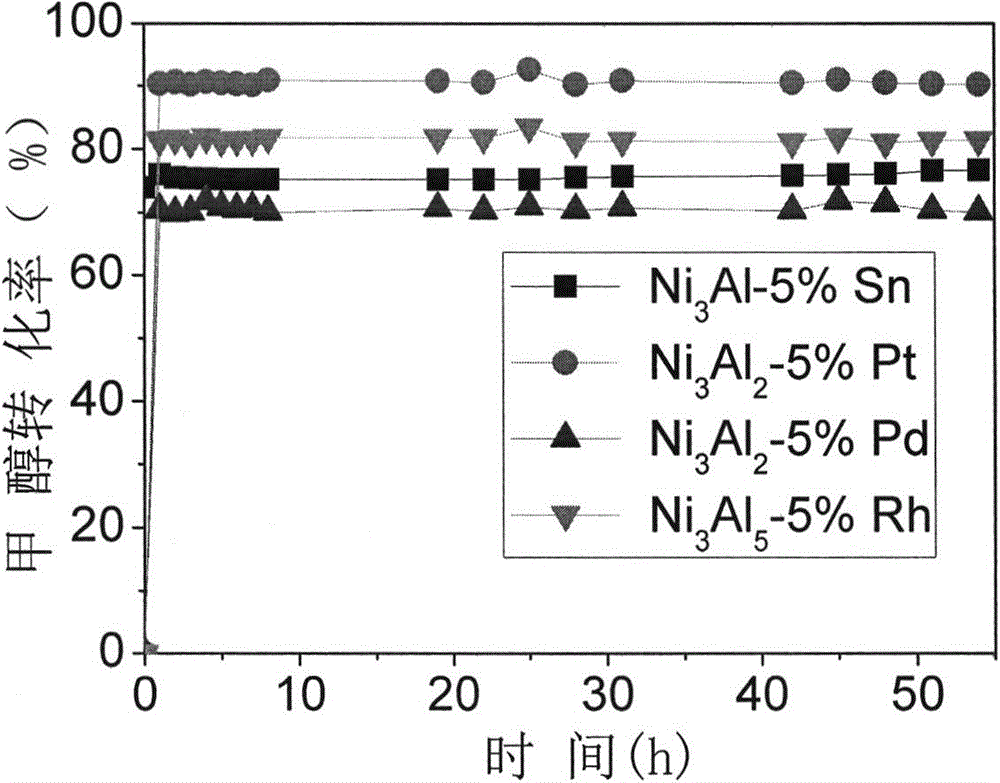

[0043] Catalyst activity test; weigh 0.2g catalyst and put it into the reactor, methanol flow rate is 25ul / min; reaction temperature is 320~520℃; see Figure 4 with 5 ; The catalyst has good catalytic activity and hydrogen selectivity. The conversion rate of methanol is greater than 50%; the selectivity of hydrogen is greater than 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com