Method for activating adiponitrile hydrogenation catalyst

A technology of hydrogenation catalyst and activation method, which is applied in the field of activation of adiponitrile hydrogenation catalyst, can solve the problems of oxidation and dissolution reaction loss, catalyst surface loss, catalyst activity reduction, etc., and achieve the effect of reducing loss and large active specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

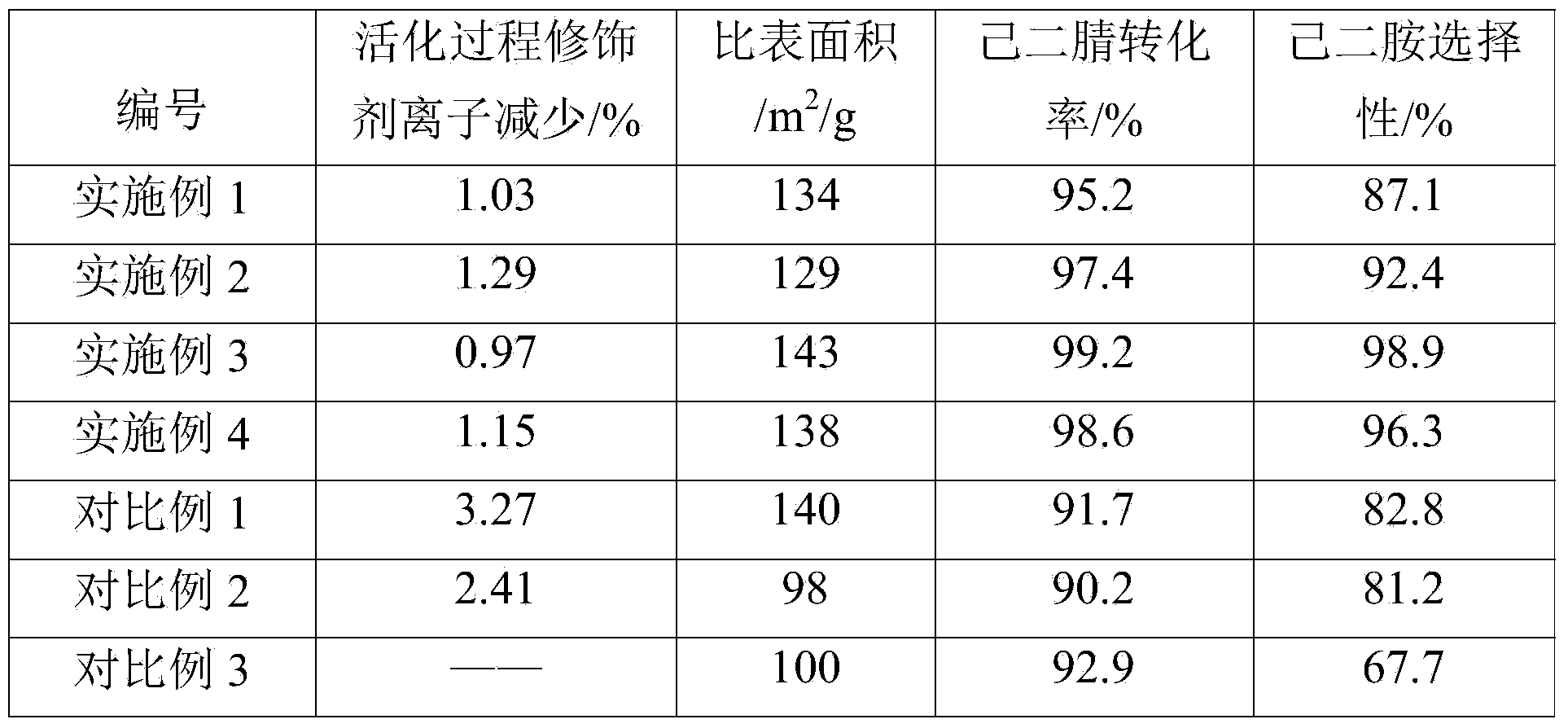

Examples

Embodiment 1

[0025] 1. Preparation of modified Raney nickel catalyst:

[0026] The nickel-aluminum alloy that contains nickel is 50wt% is ground into 60-80 purpose powder, under ice-water bath condition, gets 100g and joins in the NaOH of 0.2mol / l, ammonium chloride, ammoniacal liquor mixed solution while stirring, its The molar ratio is 5:1:0.1; react at 20°C for 0.5h to partially dissolve the aluminum, remove the upper layer of lye and wash it with deionized water to neutrality, and then wash it several times with absolute ethanol; under the condition of 600w30000MHz microwave, Add the above powder into a mixed solution composed of ferric nitrate solution and chromium nitrate, wherein the molar ratio of iron to nickel is 0.01:1, and the molar ratio of chromium to nickel is 0.01:1; microwave heating to 80°C for hydrothermal aging for 1h , filtered and separated to obtain solid particles, after drying and roasting, hydrogen reduction was introduced at 0.1MPa500°C for 4h to obtain a modifie...

Embodiment 2

[0030] 1. Preparation of modified Raney nickel catalyst:

[0031] Grind the nickel-aluminum alloy containing 50wt% nickel into 60-80 mesh powder, take 100g and add it to 0.5mol / l NaOH, ammonium sulfate and ammonia mixed solution while stirring under ice-water bath condition, the mole The ratio is 10:1:1; react at 30°C for 1 hour to partially dissolve the aluminum, remove the upper layer of lye and wash it with deionized water until neutral, and then wash it several times with absolute ethanol; under microwave conditions, the above powder Add to the mixed solution composed of ferric nitrate solution and tin nitrate, wherein the molar ratio of iron to nickel is 0.02:1, and the molar ratio of tin to nickel is 0.02:1; microwave heating to 80°C for hydrothermal aging for 1h, filter and separate The obtained solid particles were dried and calcined, and then reduced by introducing hydrogen at 0.1 MPa at 500°C for 4 hours to obtain a modified Raney nickel catalyst.

[0032] 2. Cataly...

Embodiment 3

[0035] 1. Preparation of modified Raney nickel catalyst:

[0036] Grind the nickel-aluminum alloy containing 50wt% nickel into 60-80 mesh powder, take 100g and add it into 1mol / l NaOH, ammonium nitrate, ammonia water mixed solution while stirring under ice-water bath condition, the molar ratio The ratio is 7:1:0.3; react at 40°C for 1.5h to partially dissolve the aluminum, remove the upper layer of lye and wash with deionized water until neutral, and then wash with absolute ethanol several times; under the condition of 600w30000MHz microwave, the above Add the powder into a mixed solution composed of ferric nitrate solution and bismuth nitrate, wherein the molar ratio of iron to nickel is 0.05:1, and the molar ratio of bismuth to nickel is 0.05:1; microwave heating to 80°C for hydrothermal aging for 1h, filter The solid particles were separated, dried and calcined, and reduced by introducing hydrogen at 0.1 MPa at 500°C for 4 hours to obtain a modified Raney nickel catalyst. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com