Urethane acrylate oligomer, and preparation method and ultraviolet-curing antifogging coating thereof

A polyurethane acrylate and acrylate technology, applied in the polymer field, can solve the problems of poor anti-fog durability of UV-cured coatings, and achieve excellent anti-fog durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

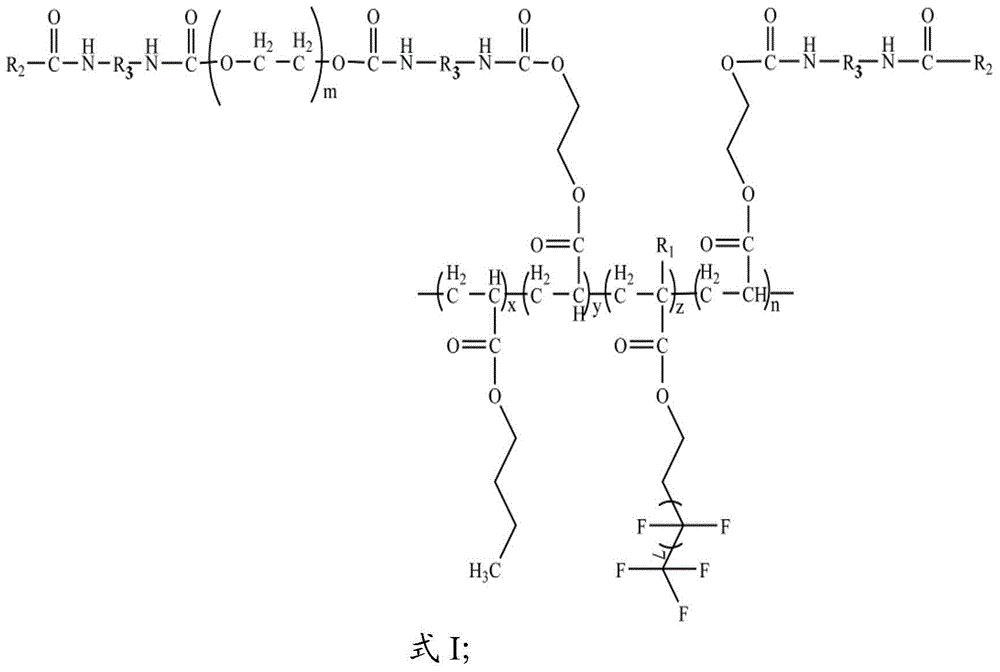

[0053] The present invention provides a kind of preparation method of polyurethane acrylate oligomer described in above-mentioned technical scheme, comprises the following steps:

[0054] a) under nitrogen or inert gas conditions, reacting hydroxyethyl acrylate, alkyl acrylate, fluorine-containing acrylate, alcohol ether compound, initiator and chain transfer agent to obtain the first intermediate;

[0055] b) reacting polyethylene glycol and diisocyanate with the first intermediate obtained in step a) to obtain a second intermediate;

[0056] c) in the presence of a catalyst and a polymerization inhibitor, reacting the acrylate containing a hydroxyl group with the second intermediate obtained in the step b) to obtain a polyurethane acrylate oligomer having the structure shown in formula I.

[0057]The present invention reacts hydroxyethyl acrylate, alkyl acrylate, fluorine-containing acrylate, alcohol ether compound, initiator and chain transfer agent under the condition of n...

Embodiment 1

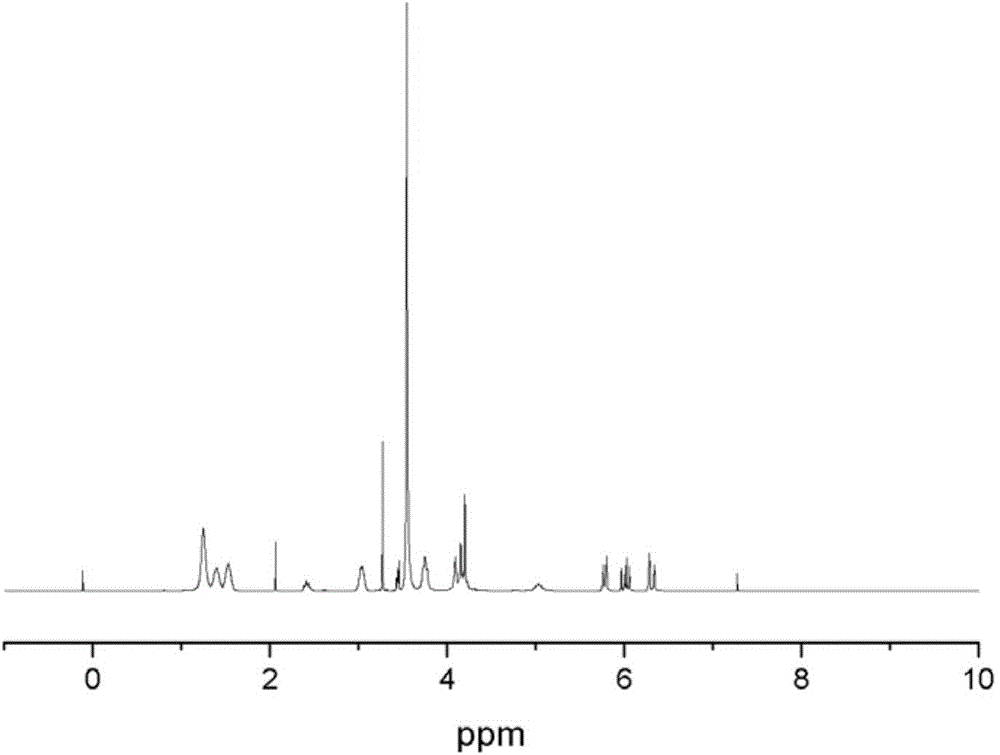

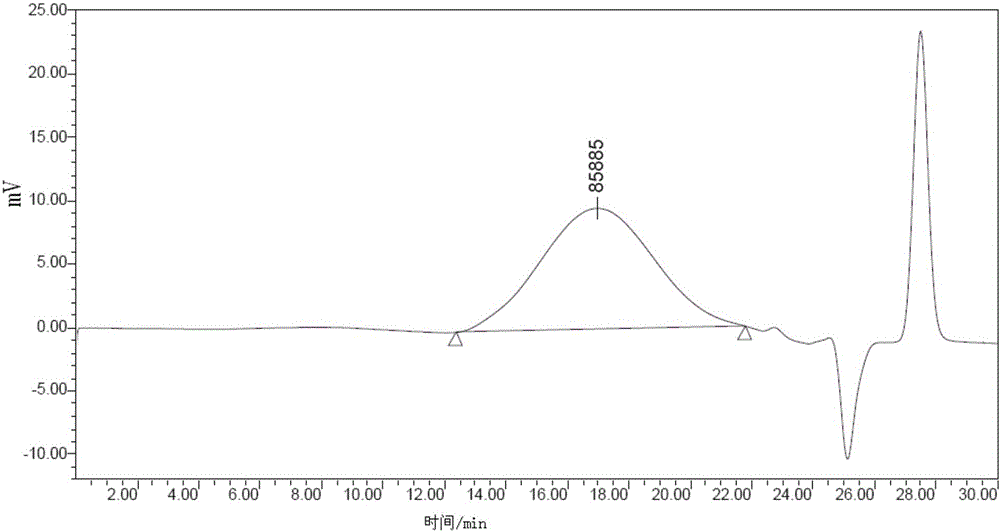

[0118] In the present invention, under the protection of nitrogen, 58g of hydroxyethyl acrylate, 10g of butyl acrylate, 78g of 1H, 1H, 2H, 2H-perfluorodecyl acrylate and 160g of diethylene glycol butyl ether are added to a three-necked flask, and the temperature is raised to 100°C. , add 5.5g of azobisisobutyronitrile in 3 batches, continue to react for 2h, add 0.4g of dodecyl mercaptan, and react at 120°C for 1h to obtain the first intermediate;

[0119] Under nitrogen protection, add 42 g of polyethylene glycol with a molecular weight of 400 Daltons to the first intermediate, cool down to 75 ° C, stir for 20 min, and drop 76 g of 2,4-toluene-di Isocyanate, after adding, continue to stir for 2h to obtain the second intermediate;

[0120] Under nitrogen protection, raise the temperature of the second intermediate to 85°C, add 0.26g of dibutyltin dilaurate and 2.63g of hydroquinone, then lower the temperature to 70°C, and add 45g of Hydroxyethyl acrylate, continue to react for...

Embodiment 2

[0126] The present invention adds 110g hydroxyethyl acrylate, 18g butyl acrylate, 140g perfluoroalkyl ethyl methacrylate (Mn=534) and 220g diethylene glycol butyl ether in a three-necked flask under nitrogen protection, and heats up to At 110°C, 8.7 g of azobisisobutyronitrile was added in 3 batches, and the reaction was continued for 6 hours. Add 1.6g of dodecyl mercaptan and react at 130°C for 3h to obtain the first intermediate;

[0127]Under nitrogen protection, add 178g of polyethylene glycol with a molecular weight of 800 Daltons to the first intermediate, cool down to 80°C, stir for 20min, add 210g of isophorone diisocyanate dropwise at a speed of 14mL / min, and complete the addition Then continue stirring for 4h to obtain the second intermediate;

[0128] Under the protection of nitrogen, the temperature of the second intermediate was raised to 90°C, 0.48g of stannous octoate and 3.85g of p-hydroxyanisole were added, and then the temperature was lowered to 75°C, and 83...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com