Halogen-free flame-retardant thermosetting resin composition of integrated circuit, prepreg and laminate

A resin composition and integrated circuit technology, applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., can solve the problems of low dielectric constant, reduced heat and humidity resistance of plates, and high dielectric strength of water absorption. Constant and other issues, to achieve the effect of reducing the dielectric constant, reducing the thermal expansion coefficient, and low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0058] Preparation 1 of phosphorus-containing active ester compound:

[0059] Weigh 0.6mol of 10-(2,5-dihydroxyphenyl)-10-hydrogen-9-oxa-10-phosphaphenanthrene-10-oxide and 0.6mol of p-hydroxybenzaldehyde, add 65% mass Concentration of H 2 SO 4 , condensed and refluxed at 100°C for 3 to 5 hours, and then the mixture was washed with alcohol 4 to 6 times to obtain the pre-product; the above-mentioned pre-product was dissolved in toluene solution, and 0.2mol of benzoic acid was added. temperature conditions, add 0.05mol catalyst (AlCl 3 ), condensed and refluxed for 4 hours, and then after several times of washing, dried for 4 hours under vacuum at 105°C to obtain the desired phosphorus-containing active ester compound with an esterification rate of 70-80% and a phosphorus content of 6.4%. Phosphorus-containing active ester compound, the specific structure is as follows:

[0060]

[0061] X= , Y=H, Z= , R is phenyl, R1=CH 3 , n is 3~5.

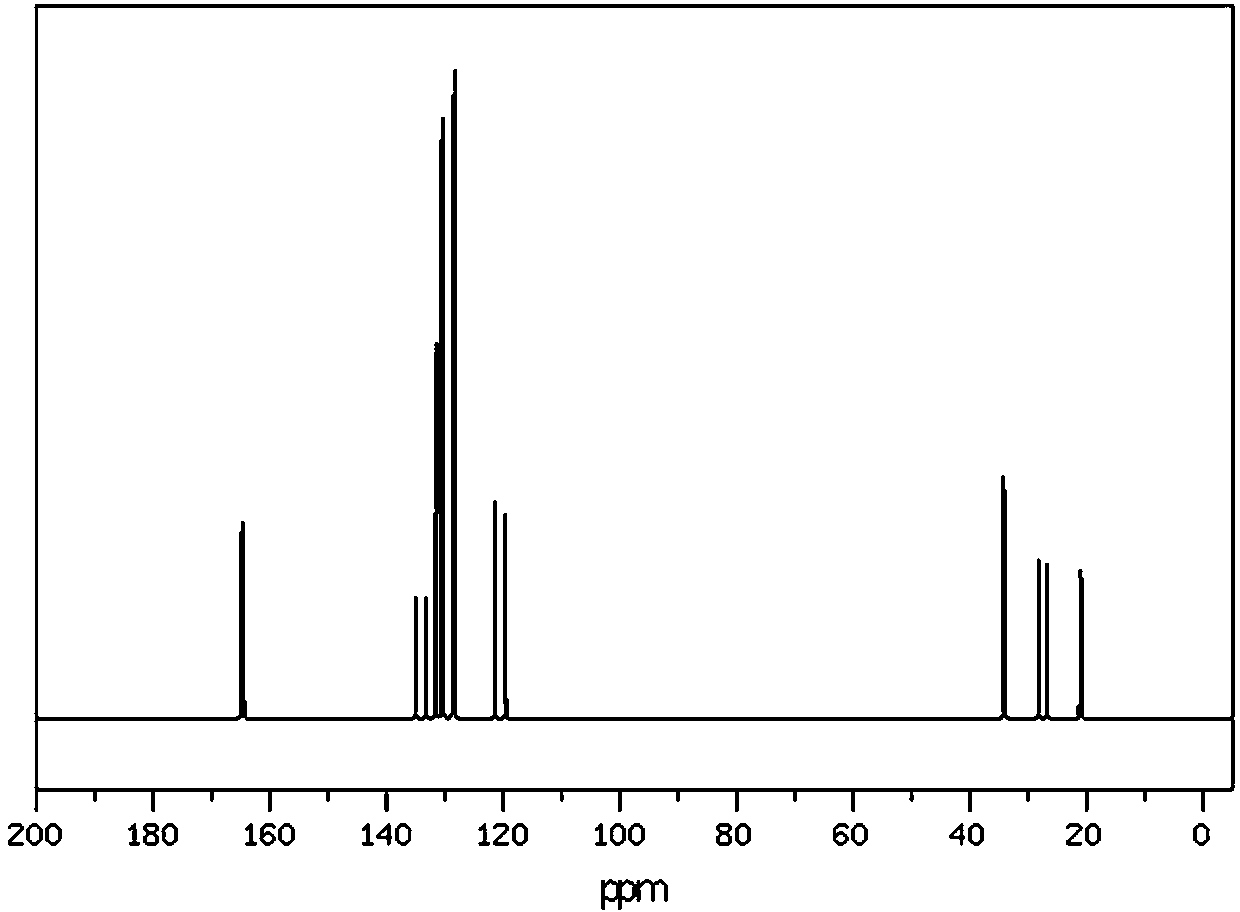

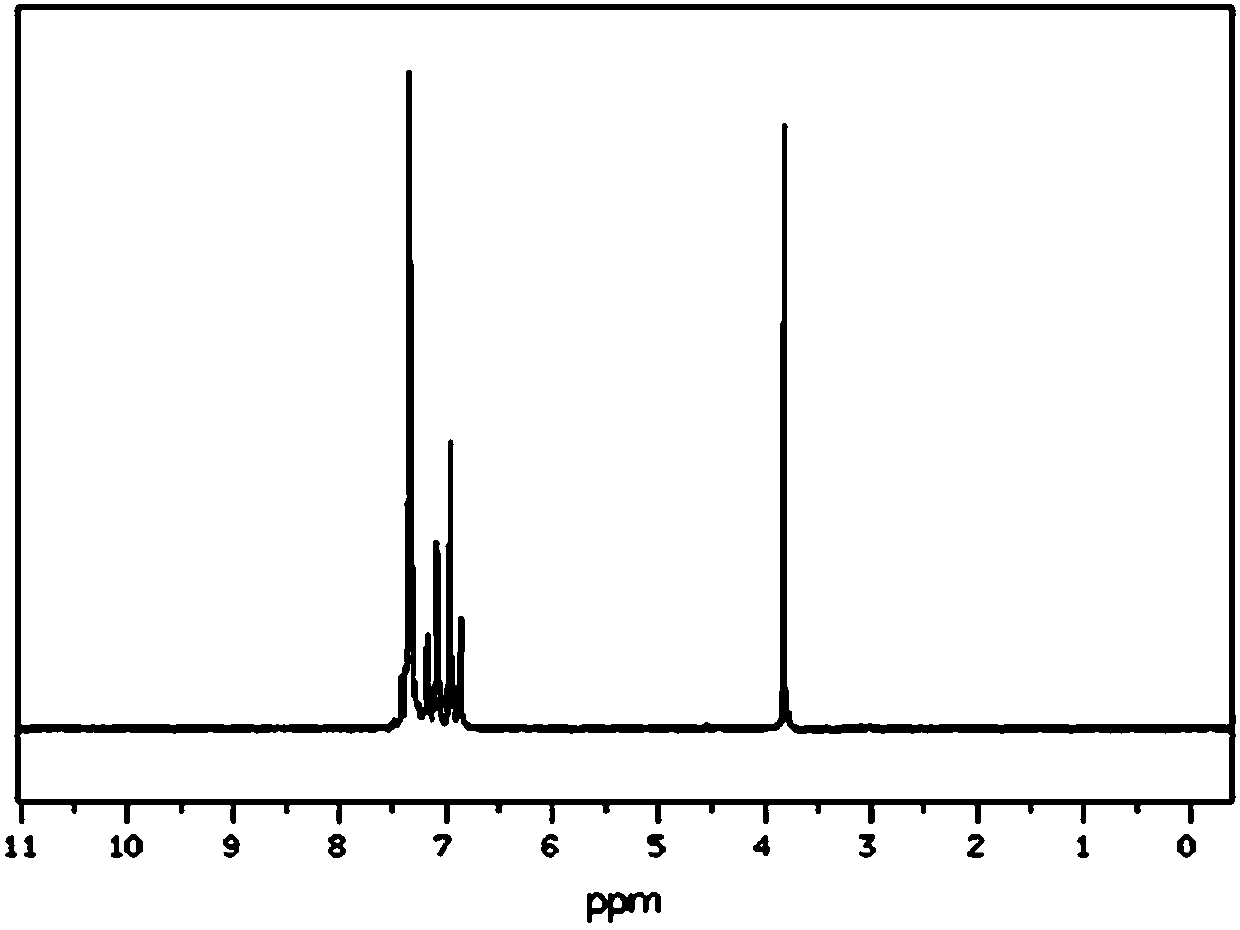

[0062] The NMR spectrum of th...

Synthetic example 2

[0067] Synthesis Example 2: Synthesis of Allyl Modified Bismaleimide Prepolymer

[0068] React 100 parts of 4,4'-diphenylmethane bismaleimide resin with 50 parts of diallyl bisphenol A compound at 135°C for 80 minutes, then cool to room temperature to obtain the desired olefin Propyl modified bismaleimide resin prepolymer A1, its molecular weight is 2000~4000g / mol;

[0069] React 100 parts of 4,4'-diphenyl ether bismaleimide resin with 100 parts of diallyl bisphenol A allyl compound at 155°C for 50 minutes, then cool to room temperature to obtain the obtained The desired allyl-modified bismaleimide resin prepolymer A2 has a molecular weight of 4001-6000 g / mol.

Embodiment

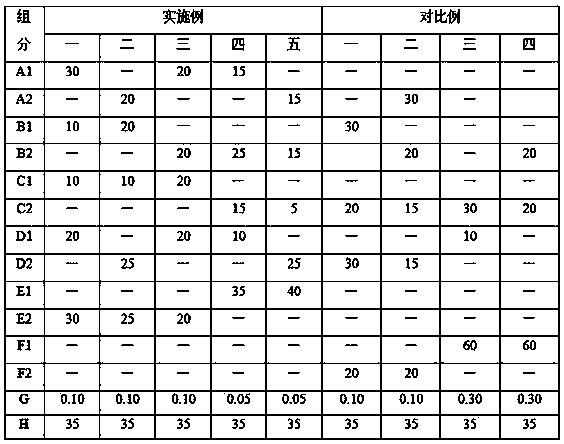

[0071] Allyl modified bismaleimide prepolymer, benzoxazine resin, acid anhydride compound, epoxy resin, phosphorus-containing active ester compound, curing accelerator, inorganic filler and solvent according to the weight ratio shown in table 1 Add it into the rubber mixing kettle, control the solid content of the glue solution to 65%, stir evenly, and ripen it for 8hr to make the resin composition glue solution; then impregnate the glass cloth in the above resin composition glue solution; then soak the impregnated The glass cloth is baked at 155~175°C for 4~7 minutes to form a prepreg; after cutting the prepreg to a certain size, stack 8 prepregs to form a stack, and place an electrolytic copper foil on the top and bottom of the stack. Send them into a vacuum press for pressing, the program is 150°C / 60min+200°C / 120min, to obtain a laminate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com