Microcapsule phase change energy storage material with photoluminescence characteristic and preparation method thereof

A phase-change energy storage material and photoluminescence technology, which is applied in the direction of luminescent materials, microcapsule preparations, microsphere preparation, etc., to achieve high thermal conductivity, easy control of the reaction process, and good light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] At 45°C and 450rpm stirring speed, add 20g n-eicosane and 2g emulsifier PEO–PPO–PEO into 400mL formamide solution and stir for 2-3 hours to obtain a stable O / W emulsion; add 20g zirconium Precursor zirconium n-propoxide, react for 1 to 2 hours to disperse zirconium n-propoxide evenly; add 200mL deionized water and formamide mixed solution (volume ratio 1:1) as initiator, add 5g crystallization accelerator NaF, and heat up to 70°C, react for 10-16 hours; stop stirring, keep warm for 8 hours; cool, wash 2-3 times with petroleum ether, filter and separate the emulsion, wash 2-3 times with deionized water and absolute ethanol, and dry to obtain crystalline light Luminescent zirconia microcapsule phase change energy storage material.

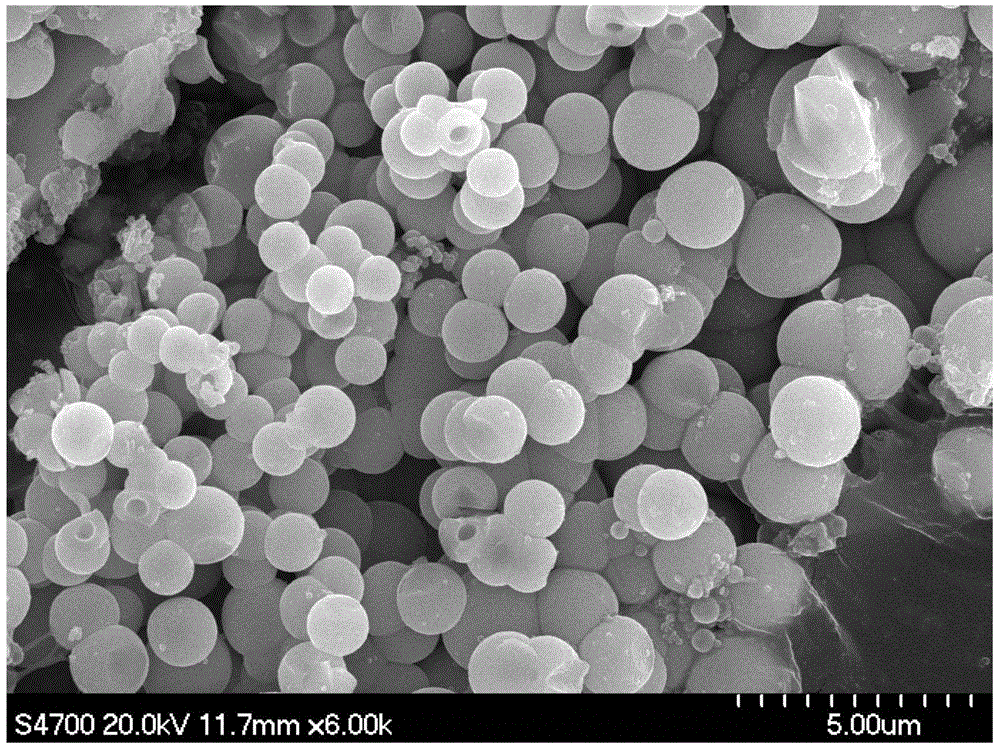

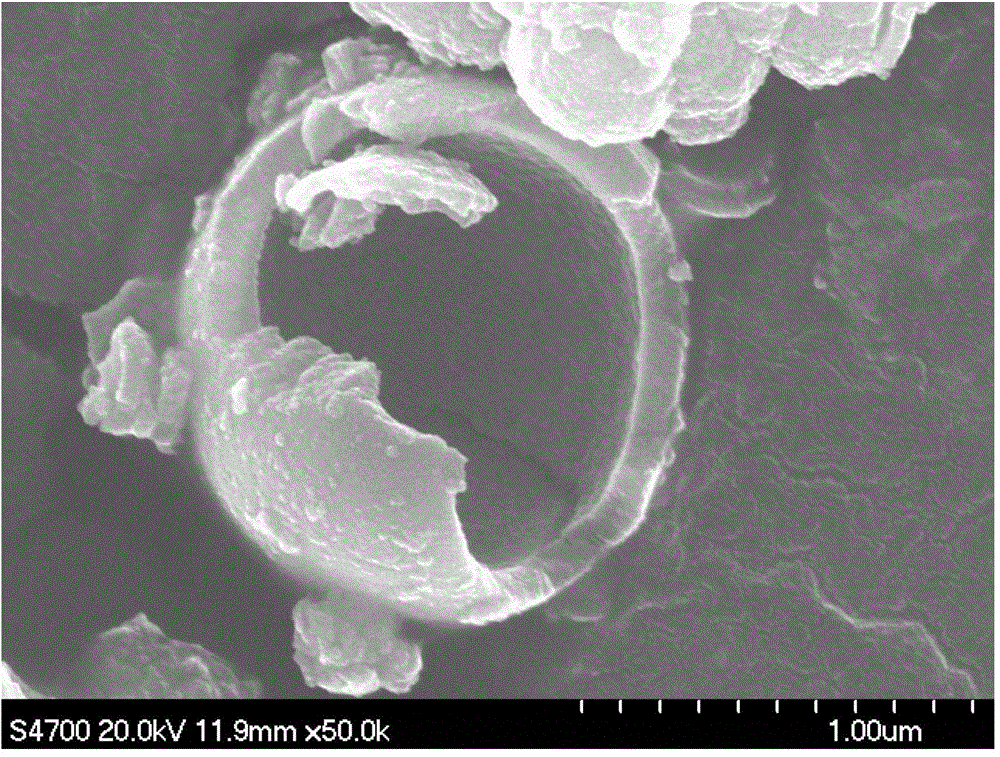

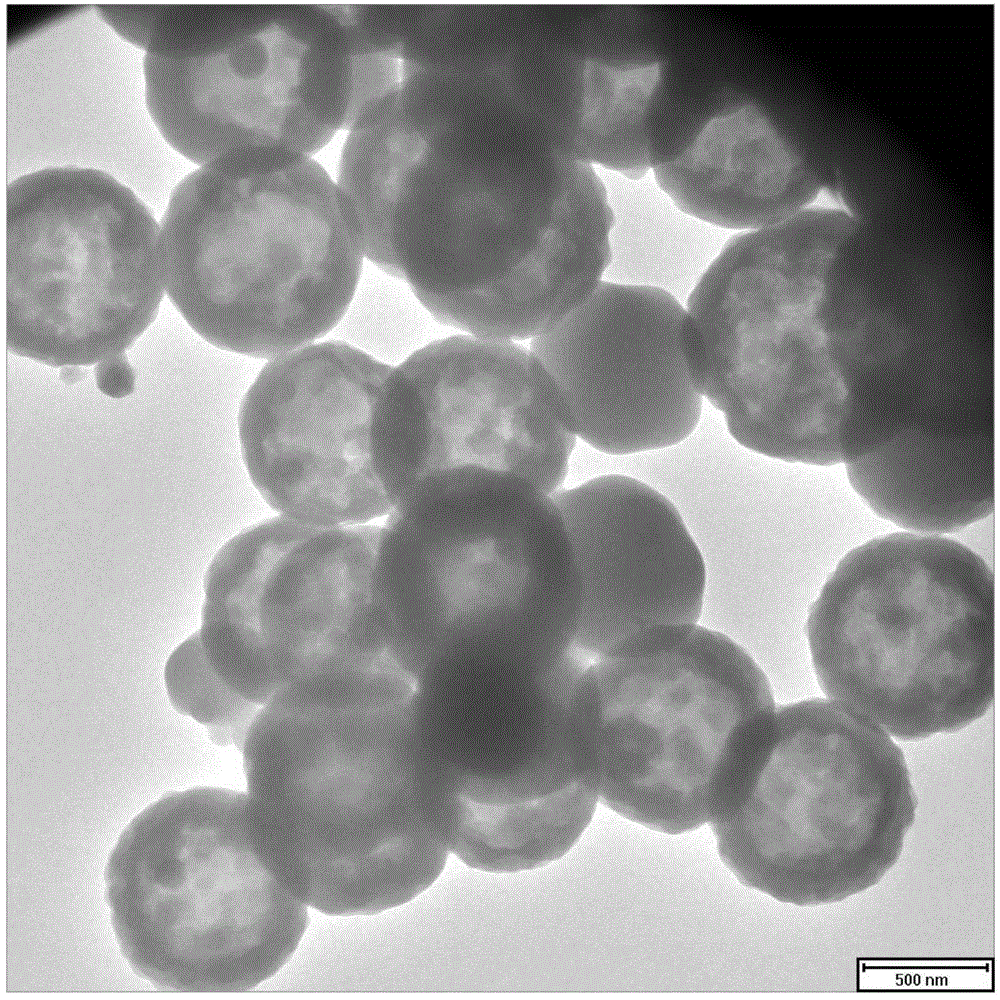

[0034] The obtained tetragonal crystal form (such as Figure 4 ) zirconia-coated microcapsule phase-change energy storage material, its surface is smooth (such as figure 1 ), with a regular "core-shell" structure (such as figure 2 , imag...

Embodiment 2

[0036] Add 30g n-nonadecane and 2g emulsifier Span60 into 400mL formamide solution at 45°C and 500rpm stirring speed, and after stirring for 2-3 hours, a stable O / W emulsion is obtained; add 20g zirconium precursor n-butyl Zirconium alkoxide, react for 1-2 hours, so that zirconium n-butoxide is uniformly dispersed; add 200mL deionized water and formamide mixed solution (volume ratio 1:1) as an initiator, add 3mL crystallization accelerator H 3 PO 4 , and heated to 70°C, reacted for 10-16 hours; stopped stirring, kept warm for 8 hours; cooled, first washed 2-3 times with petroleum ether, filtered to separate the emulsion, washed 2-3 times with deionized water and absolute ethanol, and dried to obtain Crystalline photoluminescence zirconia microcapsule phase change energy storage material.

[0037] The obtained tetragonal zirconia-coated microcapsule phase-change energy storage material has a smooth surface and a regular "core-shell" structure. The particle size of the microcap...

Embodiment 3

[0039] At 45°C and 450rpm stirring speed, 20g of n-octadecane and 2g of emulsifier Span80 were added to 400mL of ethanol / acetylacetone mixed solution (volume ratio 1:1), and after stirring for 2 to 3 hours, a stable O / W emulsion; add 30g of zirconium precursor zirconium tert-butoxide, 2g of yttrium nitrate hexahydrate, react for 1-2h, so that zirconium tert-butoxide and yttrium nitrate hexahydrate are dispersed evenly; add 300mL deionized water and formamide mixed solution (volume Ratio 1:1) as initiator, add 4.4g crystallization accelerator NH 4 F, and heat up to 70°C, react for 10-16 hours; stop stirring, keep warm for 8 hours; cool, wash with petroleum ether for 2-3 times, filter and separate the emulsion, wash with deionized water and absolute ethanol for 2-3 times, and dry A crystalline photoluminescent zirconia microcapsule phase-change energy storage material doped with yttrium element is obtained.

[0040] The obtained yttrium-doped tetragonal zirconia-coated microca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com