Low-cost preparing method for high-temperature superconductive coated conductor strip

A high-temperature superconducting and coated conductor technology, applied in the usage of superconducting elements, superconducting/high-conducting conductors, cable/conductor manufacturing, etc., can solve the problems of low conversion rate, high cost, and expensive organic sources, etc., to achieve The effect of high growth speed, relatively low cost and high production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

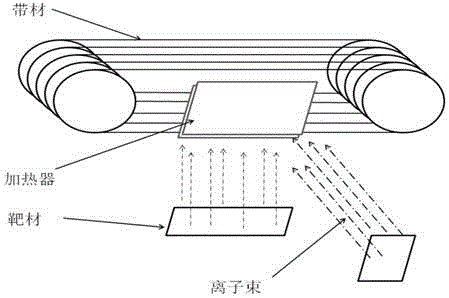

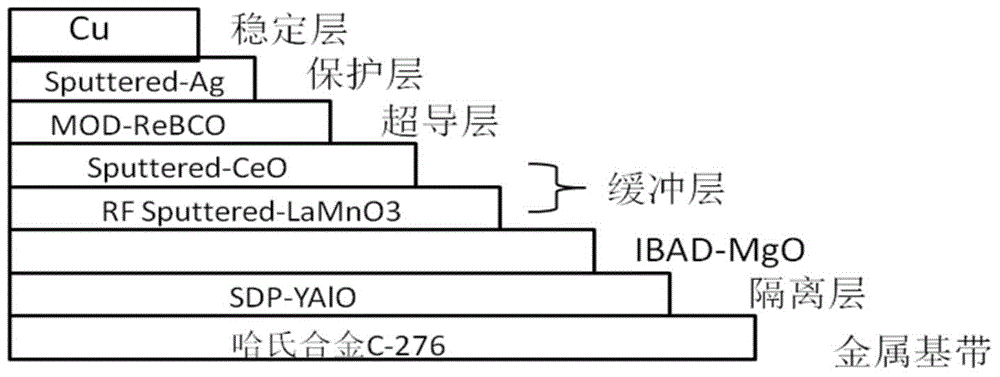

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: The preparation of a high-temperature superconducting coated conductor strip on Hastelloy C-276 includes the following steps:

[0033] (1) Preparation of precursor solution 1: Dissolve aluminum nitrate and ethanol solvent in a predetermined ratio, and use ultrasonic vibration to speed up the dissolution. After it is completely dissolved, add a certain proportion of yttrium acetate, stir and heat to 60 degrees to speed up the dissolution, and then add ethanol , so that in the precursor solution 1, the concentration ratio of aluminum ions to yttrium ions is 1:1, and the concentration of aluminum ions is 0.1 mol / l.

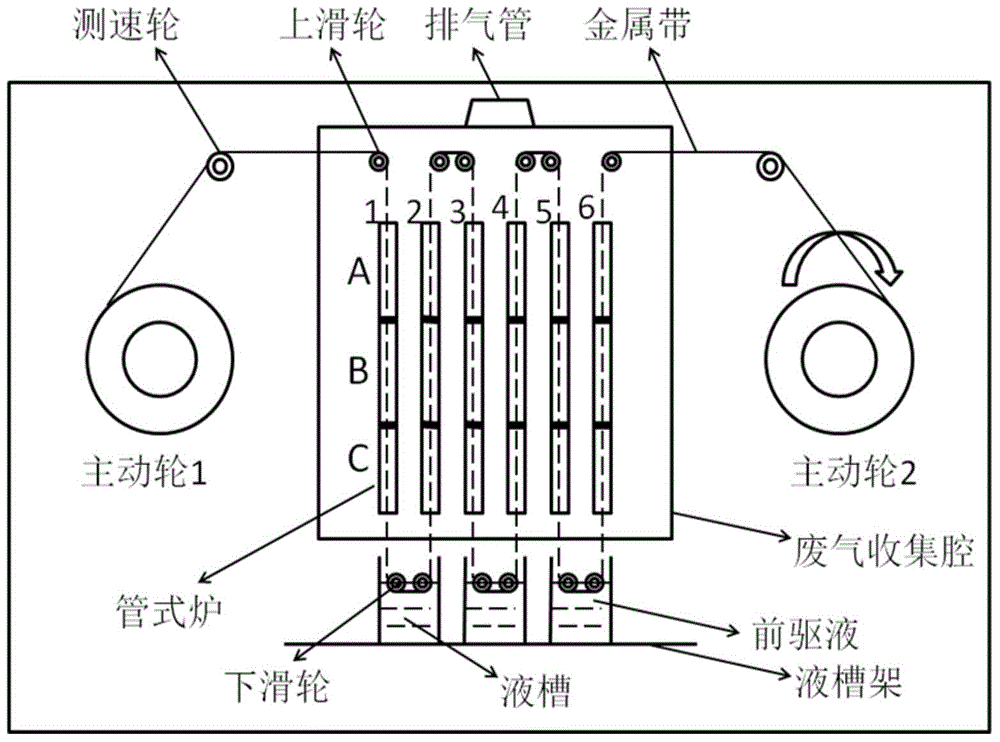

[0034] (2) Acetone cleaning of the metal substrate: press figure 2 Install the flexible metal strip as shown, pour 1800 ml of acetone into the figure 2 In the three liquid tanks shown, it is guaranteed that the metal strip can be submerged. The three liquid tanks are placed in an ultrasonic container filled with water, and the ultrasonic equip...

Embodiment 2

[0045] Embodiment 2: The preparation of a high-temperature superconducting coated conductor strip on Hastelloy C-276 includes the following steps:

[0046] (1) Preparation of precursor solution 1: Dissolve aluminum nitrate and ethanol solvent in a predetermined ratio, and use ultrasonic vibration to speed up the dissolution. After it is completely dissolved, add a certain proportion of yttrium acetate, stir and heat to 60 degrees to speed up the dissolution, and then add ethanol , so that in the precursor solution 1, the concentration ratio of aluminum ions to yttrium ions is 1:1, and the concentration of aluminum ions is 0.2 mol / l.

[0047] (2) Acetone cleaning of the metal substrate: press figure 2 Install the flexible metal strip as shown, pour 1800 ml of acetone into the figure 2 In the three liquid tanks shown, it is guaranteed that the metal strip can be submerged. The three liquid tanks are placed in an ultrasonic container filled with water, and the ultrasonic equip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface average roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com