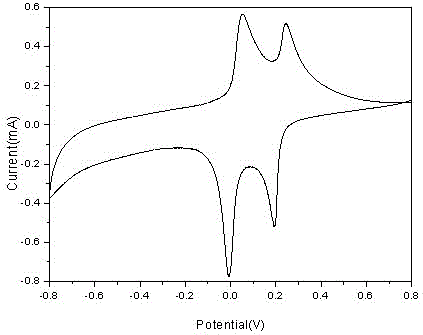

Method for preparing vanadium pentoxide/conductive substrate composite electrode material

A technology of vanadium pentoxide and conductive substrates, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problem of low electronic conductivity and ion conductivity, unstable structure, difficult Commercial applications and other issues, to achieve faster transport speed, good contact, and weaken the effect of sample morphology being destroyed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

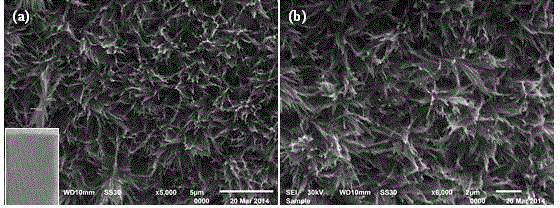

Embodiment 1

[0025] a Clean the stainless steel wire mesh, and put the cleaned stainless steel wire mesh into the lining of the high-pressure reactor.

[0026] b Ultrasonic mixing ammonium metavanadate, oxalic acid and sodium dodecylbenzenesulfonate in deionized water to form a mixed solution, wherein the concentration of ammonium metavanadate is 0.2mol / L, and the concentration of oxalic acid is 0.4mol / L, The concentration of sodium dodecylbenzenesulfonate is 0.05mol / L.

[0027] c Transfer the mixed solution prepared in step b to the inner lining of the autoclave equipped with stainless steel wire mesh, react at 100°C for 30 minutes, take out the autoclave and cool it naturally at room temperature, and put the reaction load with di The stainless steel metal mesh of the vanadium precursor was taken out, washed with deionized water, and dried in an oven at 30°C.

[0028] d Take the dried stainless steel metal mesh loaded with vanadium pentoxide precursor obtained in step c, heat it to 300°C...

Embodiment 2

[0030] a Clean the stainless steel wire mesh, and put the cleaned stainless steel wire mesh into the lining of the high-pressure reactor.

[0031] b Ultrasonic mixing ammonium metavanadate, oxalic acid and sodium dodecylbenzenesulfonate in deionized water to form a mixed solution, wherein the concentration of ammonium metavanadate is 1mol / L, the concentration of oxalic acid is 3mol / L, dodecylbenzenesulfonate The concentration of sodium alkylbenzenesulfonate is 0.17mol / L.

[0032] c Transfer the mixed solution prepared in step b to the inner lining of the autoclave equipped with stainless steel wire mesh, react at 180°C for 90 minutes, take out the autoclave and cool it naturally at room temperature, and put the reaction load with di The stainless steel metal mesh of the vanadium precursor was taken out, washed with deionized water, and dried in an oven at 100°C.

[0033] d Take the dried stainless steel metal mesh loaded with vanadium pentoxide precursor obtained in step c, h...

Embodiment 3

[0035] a Clean the stainless steel wire mesh, and put the cleaned stainless steel wire mesh into the lining of the high-pressure reactor.

[0036] b Ultrasonic mixing of ammonium metavanadate, oxalic acid, and hexamethylenetetramine in deionized water is made into a mixed solution, wherein the concentration of ammonium metavanadate is 0.5mol / L, the concentration of oxalic acid is 1mol / L, and the concentration of hexamethylenetetramine The concentration of tetramine is 0.1mol / L.

[0037] c Transfer the mixed solution prepared in step b to the inner lining of the autoclave equipped with stainless steel wire mesh, react at 150°C for 50 minutes, take out the autoclave and cool it naturally at room temperature, and put the reaction load with di The stainless steel metal mesh of the vanadium precursor was taken out, washed with deionized water, and dried in an oven at 60°C.

[0038]d Take the dried stainless steel metal mesh loaded with vanadium pentoxide precursor obtained in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com