Three-dimensional scaffold material for bone tissue repair and preparation method thereof

A three-dimensional scaffold and bone tissue technology, used in medical science, prosthesis, etc., can solve the problems of limited application, poor mechanical properties of microporous scaffolds, easy deformation, etc., achieve excellent mechanical properties, be conducive to repair and regeneration, and promote regeneration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

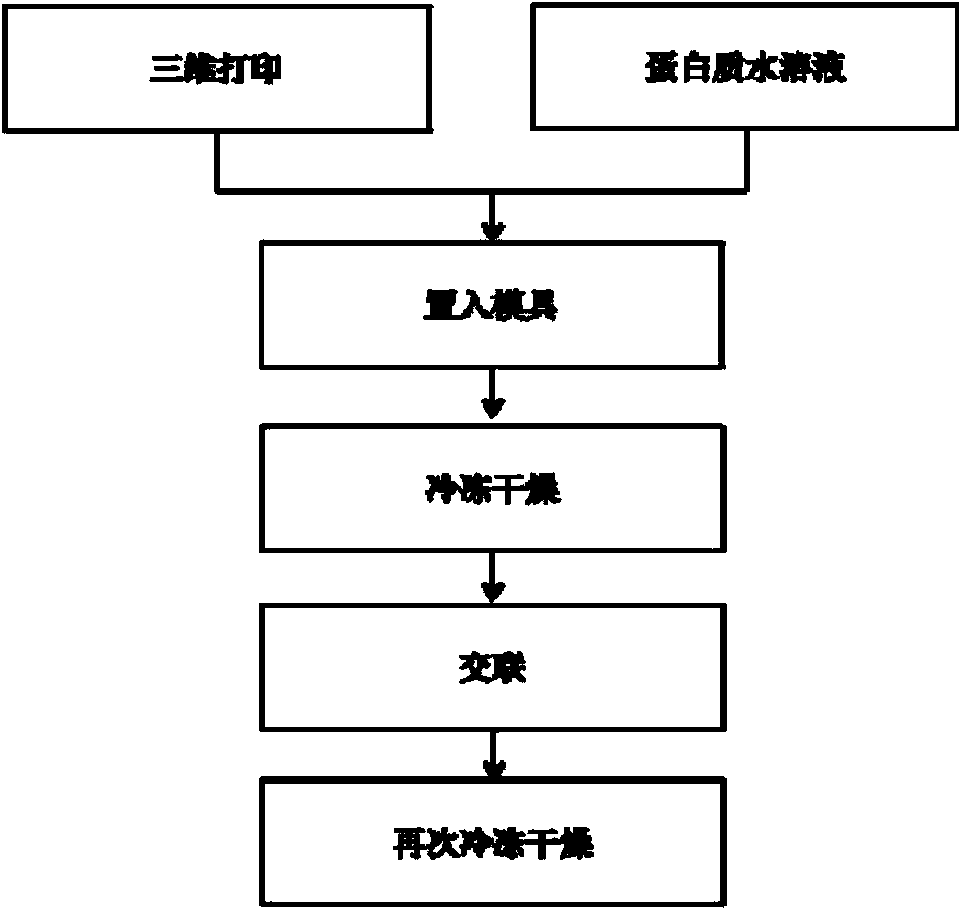

Method used

Image

Examples

Embodiment 1

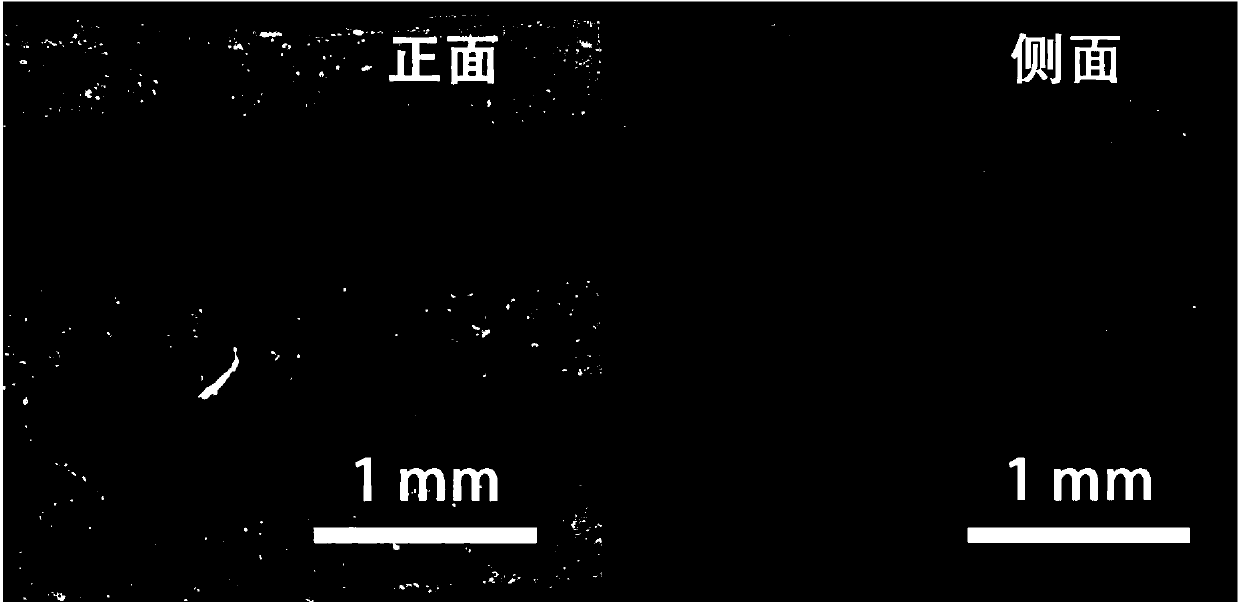

[0038] (a) Polycaprolactone (PCL, molecular weight 65,000) is heated to 60 degrees Celsius and extruded from a needle with an inner diameter of 0.4 mm to form a 0.4 mm PCL fluid. The moving speed of the receiving plate is 0.05 mm / s, and the polymer extrusion rate 0.05 mm / s, the fluid spacing is 0.5 mm, the layers are vertically arranged, the layer height is 0.3 mm, and the number of layers is 7 layers, forming a cylindrical PCL skeleton with a diameter of 20 mm ( figure 2 , image 3 ).

[0039] (b) 1 gram of mulberry silk regenerated silk fibroin solid was dissolved in 50 milliliters of deionized water, and stirred to completely dissolve it to obtain a silk fibroin solution with a mass volume percentage of 2%.

[0040] (c) Placing the PCL skeleton in a plastic mold, and injecting the prepared silk fibroin solution to completely infiltrate and submerge the PCL skeleton. The mold was frozen in a refrigerator at -80 degrees Celsius for 12 hours, and then freeze-dried in a free...

Embodiment 2

[0044] (a) PCL is heated to 60 °C and extruded by a needle with an inner diameter of 0.4 mm to form a 0.4 mm PCL fluid, the receiving plate moving speed is 0.05 mm / s, the polymer extrusion rate is 0.05 mm / s, and the fluid spacing is 0.5 mm, the layers are arranged vertically between the layers, the layer height is 0.3 mm, and the number of layers is 7 layers to obtain a cylindrical PCL skeleton with a diameter of 14 mm.

[0045] (b) Dissolve 1 gram of gelatin (type A pigskin gelatin) and 1 gram of mulberry silk regenerated silk fibroin in 50 ml of deionized water, heat to 60 degrees Celsius and stir to completely dissolve the gelatin and silk fibroin to obtain a mass volume percentage of 4%. gelatin / silk fibroin (1:1) aqueous solution.

[0046] (c) Placing the PCL skeleton in a plastic mold, and injecting the prepared silk fibroin solution to completely infiltrate and submerge the PCL skeleton. The mold was frozen in a -80°C refrigerator for 12 hours, and then freeze-dried in...

Embodiment 3

[0049] (a) Add 3 grams of PCL into 30 milliliters of trifluoroethanol, stir to dissolve, add 1.5 grams of nano-hydroxyapatite particles after the dissolution is complete, continue to stir and ultrasonically disperse the hydroxyapatite evenly. The prepared PCL / nano-hydroxyapatite solution was poured into a metal container, and the trifluoroethanol was quickly volatilized and completely removed by heating to obtain a mixture of PCL and nano-hydroxyapatite with a mass ratio of 2 / 1. This mixture was heated to 60°C and extruded with a needle with an inner diameter of 0.5 mm to form a 0.5 mm PCL fluid with a receiving plate moving speed of 0.05 mm / s, a polymer extrusion rate of 0.05 mm / s, and a fluid spacing of 0.5 mm , the layers are arranged at 60 degrees, the layer height is 0.4 mm, and the number of layers is 9 layers to obtain a cylindrical PCL skeleton with a diameter of 20 mm.

[0050] (b) Add 0.4 g of collagen (type I pigskin collagen) into 20 ml of deionized water, stir to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com