Carbon nitride nanoparticle modified bismuth vanadate composite photocatalyst and preparation method thereof

A nanoparticle, carbon nitride technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of difficulty in fully exerting the synergistic effect of carbon nitride and bismuth vanadate, highly active phase interface Insufficient exposure, large size of composite photocatalyst, etc., to achieve the effect of superior photocatalytic performance, good visible light response performance, and improved photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

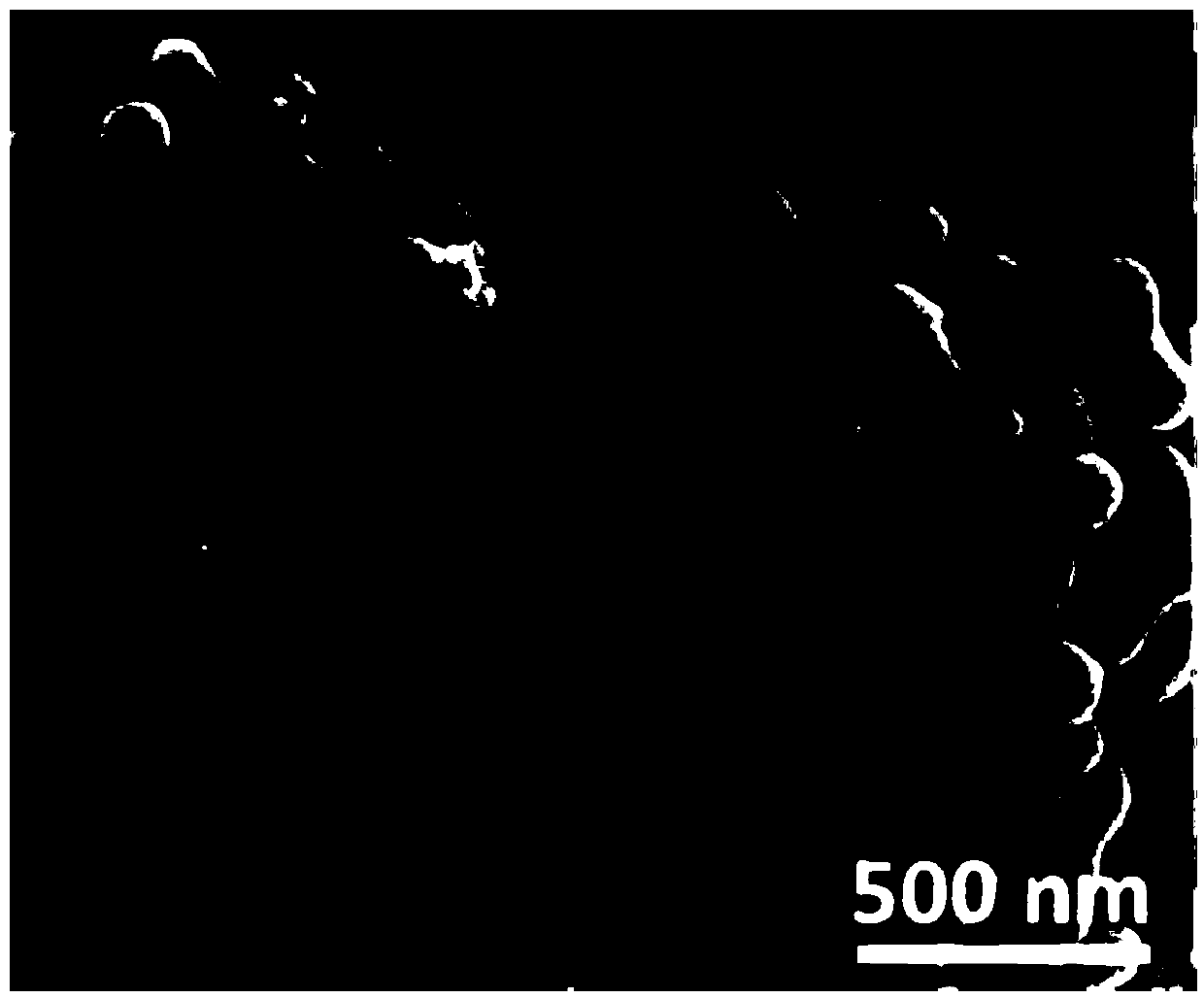

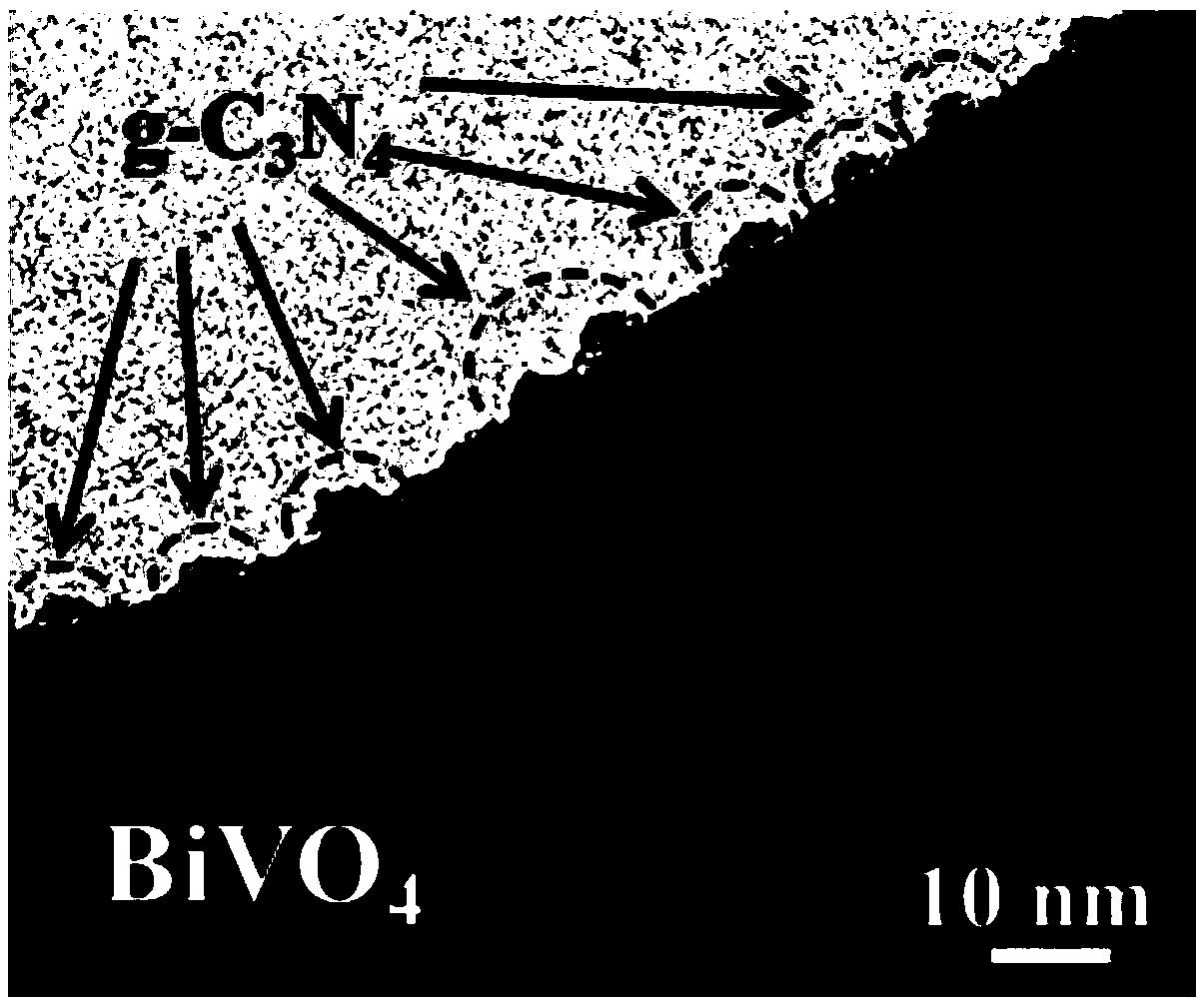

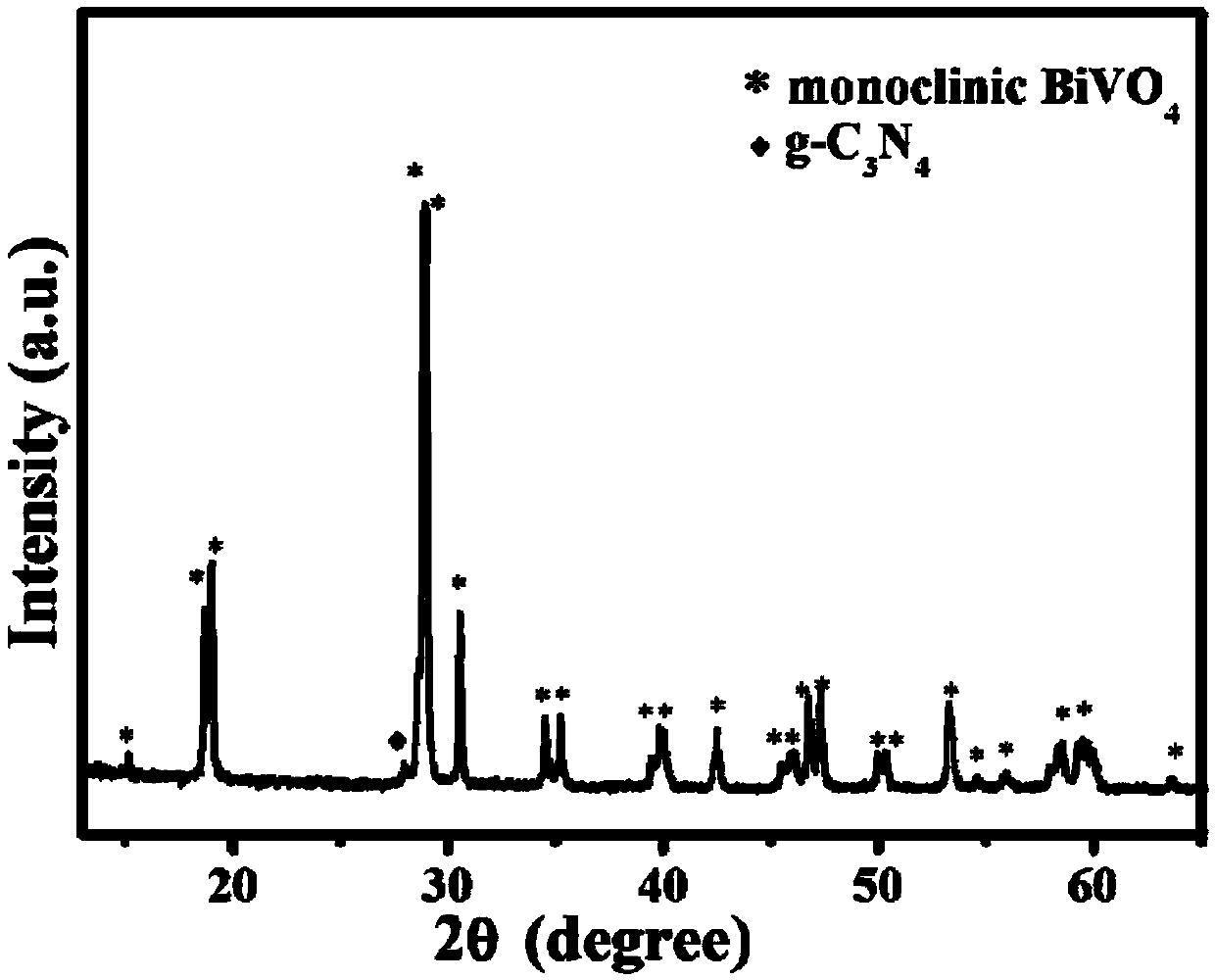

Image

Examples

Embodiment 1

[0040] The first step is to take a certain amount of melamine powder and add it to the crucible, cover the crucible to form a semi-closed environment, and then put it into the muffle furnace controlled by the temperature program, and increase the temperature by 10°C / min. The room temperature was raised to 500°C and kept at this temperature for 2h.

[0041] In the second step, the temperature of the muffle furnace was raised to 520° C. at a rate of 2° C. / min, and kept at this temperature for 2 hours for further deamination. After cooling to room temperature, the obtained product was ground in an agate mortar to obtain carbon nitride powder.

[0042] In the third step, take 15 parts (0.552 g) of carbon nitride obtained in the second step by weight, add it into high-purity water, and perform ultrasonic dispersion treatment for 30 minutes to make it uniformly dispersed.

[0043] In the fourth step, under the condition of vigorous stirring, 3 parts by weight (0.582 g) of bismuth n...

Embodiment 2

[0054] The first step is to take a certain amount of melamine powder and add it to the crucible, cover the crucible to form a semi-closed environment, and then put it into a muffle furnace controlled by temperature programming, and increase the temperature by 15°C / min. The room temperature was raised to 500°C and kept at this temperature for 4h.

[0055] In the second step, the temperature of the muffle furnace was raised to 550° C. at a rate of 2° C. / min, and kept at this temperature for 4 hours for further deamination. After cooling to room temperature, the obtained product was ground in an agate mortar to obtain carbon nitride powder.

[0056] In the third step, take 15 parts (0.552 g) of carbon nitride obtained in the second step by weight, add it into high-purity water, and perform ultrasonic dispersion treatment for 30 minutes to make it uniformly dispersed.

[0057] In the fourth step, under the condition of vigorous stirring, 3 parts by weight (0.582 g) of bismuth nit...

Embodiment 3

[0063] The first step is to take a certain amount of melamine powder and add it to the crucible, cover the crucible to form a semi-closed environment, and then put it into the muffle furnace controlled by the temperature program, and increase the temperature by 5°C / min. The room temperature was raised to 490°C and kept at this temperature for 3h.

[0064] In the second step, the temperature of the muffle furnace was raised to 540° C. at a rate of 2° C. / min, and kept at this temperature for 3 hours for further deamination. After cooling to room temperature, the obtained product was ground in an agate mortar to obtain carbon nitride powder.

[0065] In the third step, take 15 parts (0.552 g) of carbon nitride obtained in the second step by weight, add it into high-purity water, and perform ultrasonic dispersion treatment for 30 minutes to make it uniformly dispersed.

[0066] In the fourth step, under the condition of vigorous stirring, 1 part by weight (0.194 g) of bismuth nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com