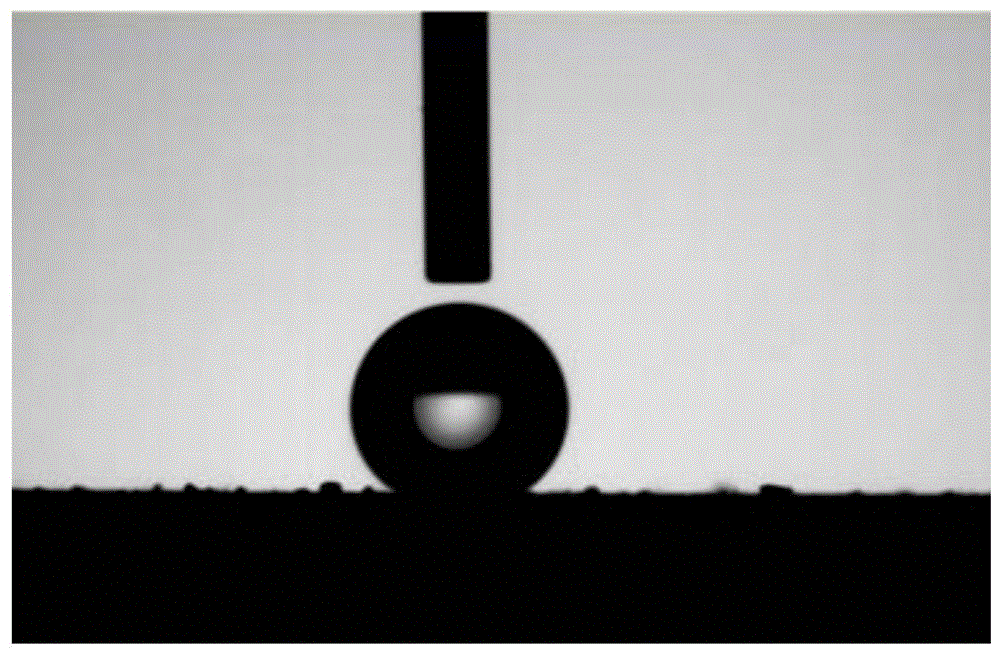

A preparation method and product of a superhydrophobic polymer composite coating containing nanoparticles

A technology of nano-particles and composite coatings, which is applied in the treatment of dyed low-molecular organic compounds, coatings, and dyed organic silicon compounds. It can solve the problems of complex preparation processes and harsh conditions, and achieve low cost and simple methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Superhydrophobic modification of nanoparticles

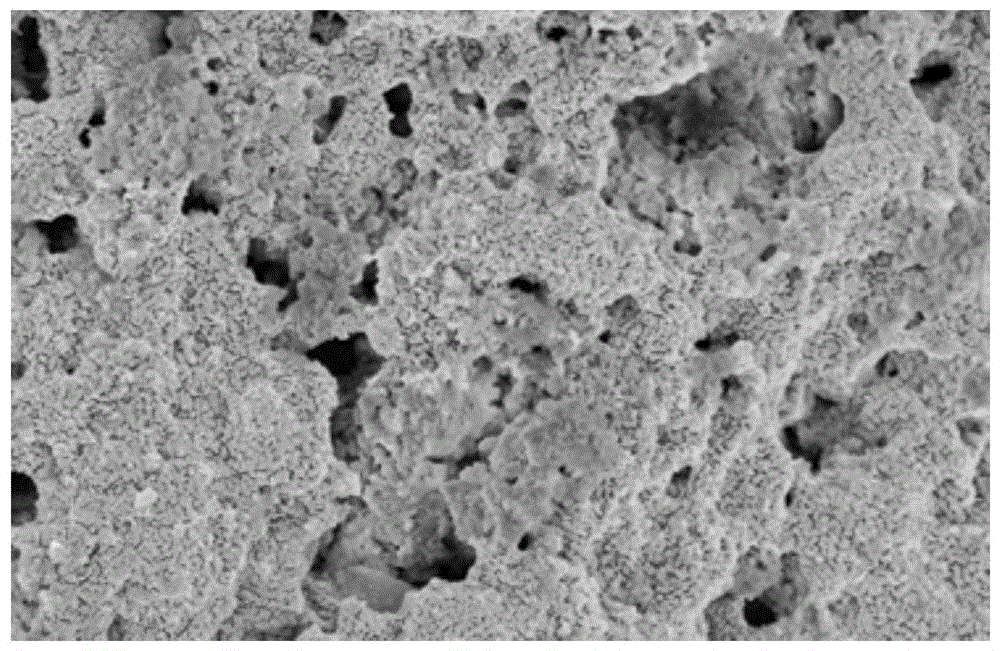

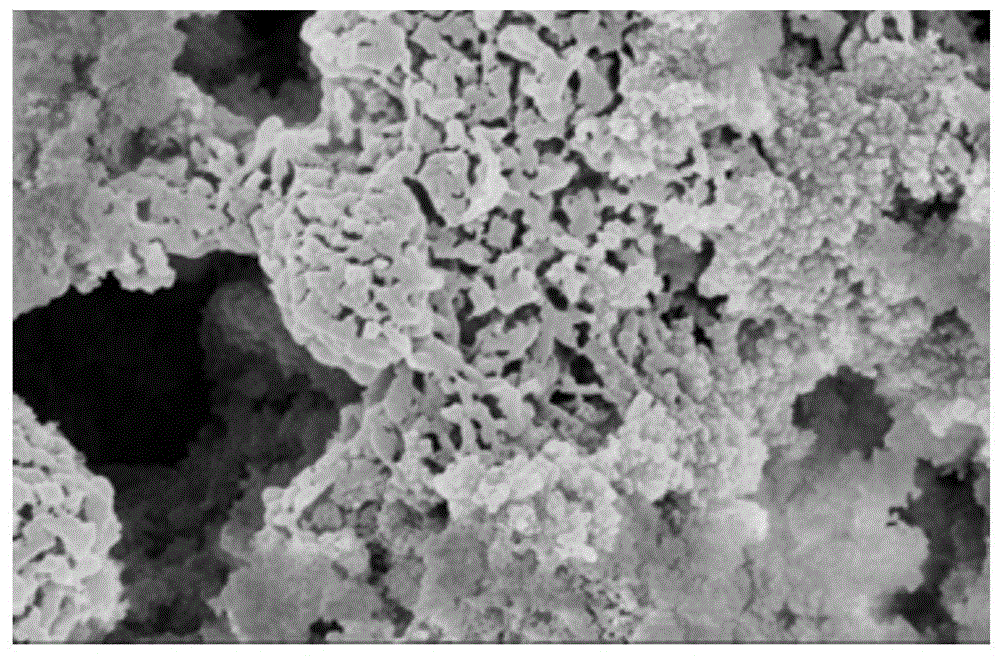

[0036] 5 mL of aminopropyltriethoxysilane (Nanjing Pinning Coupling Agent Co., Ltd., KH-550) was hydrolyzed in 10 mL of methanol and 100 mL of deionized water at room temperature for 2 h, and silica (particle size 15 ± 5nm, Aladdin Reagent Co., Ltd.) 6g modification reaction 1h. Cool to room temperature, suction filter, wash, dry at 130°C overnight and lightly grind to obtain modified particle powder. After the powder passes through a 100-mesh stainless steel sieve, take 0.12g and add it to 3.00g polyperfluoroethylene propylene emulsion (Shanghai Puchun Industrial Co., Ltd., FEPD121), dilute with 0.5g N, N-dimethylformamide to an appropriate concentration , followed by magnetic stirring for 30 minutes and ultrasonic dispersion for 20 minutes to obtain the coating.

[0037] (2) Coating and curing of paint on the surface of metal materials

[0038] The paint is applied on the steel that has been sanded and cleaned, h...

Embodiment 2

[0040] (1) Superhydrophobic modification of nanoparticles

[0041] 5 mL of glycidyl etheroxypropyl trimethoxysilane (Nanjing Pinning Coupling Agent Co., Ltd., KH-560) was hydrolyzed in 10 mL of isopropanol and 100 mL of deionized water at room temperature for 3 h, and aluminum oxide ( 30nm, Aladdin Reagent Co., Ltd.) 6g modification reaction 2h. Cool to room temperature, suction filter, wash, dry at 130°C overnight and lightly grind to obtain modified particle powder. After the powder passes through a 100-mesh stainless steel sieve, take 0.24g and add it to 3.00g polytetrafluoroethylene emulsion (Guangdong Likalong Technology Co., Ltd., viscosity is 750-800cst), dilute with 0.5g methylpyrrolidone to an appropriate concentration, and then successively The coating was obtained by magnetic stirring for 30 minutes and ultrasonic dispersion for 20 minutes.

[0042] (2) Coating and curing of paint on the surface of metal materials

[0043] The coating is applied on the aluminum m...

Embodiment 3

[0046] (1) Superhydrophobic modification of nanoparticles

[0047] 5mL of γ-(methacryloyloxy)propyltrimethoxysilane (Nanjing Pinning Coupling Agent Co., Ltd., KH-570) was hydrolyzed in 10mL of carbon tetrachloride and 100mL of deionized water at room temperature for 4 hours, and the Add 6 g of silicon dioxide (particle size: 15±5 nm, Aladdin Reagent Co., Ltd.) into the water bath for modification reaction for 3 h. Cool to room temperature, suction filter, wash, dry at 130°C overnight and lightly grind to obtain modified particle powder. After the powder passes through a 100-mesh stainless steel sieve, take 0.36g and add it to 3.00g ethylene tetrafluoroethylene copolymer emulsion (Shanghai Puchun Industrial Co., Ltd., F-40), dilute with 0.5g acetone to a suitable concentration, and then magnetically stir for 30min successively and ultrasonic dispersion for 20min to obtain the coating.

[0048] (2) Coating and curing of paint on the surface of metal materials

[0049] The pai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com