Environmentally-friendly cationic polyacrylate, and preparation method and application thereof

A polyacrylate and cationic technology, applied in the direction of water repellent addition, etc., can solve the problems of poor stability of prepared coating liquid, poor ability to resist interference of impurity ions, low cost of sizing agent, etc., and achieve excellent sizing effect , Strong anti-interference ability of impurity ions, good sizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] (1) Synthesis of natural polymer emulsifier

[0080] Add 30 parts of amphoteric starch made from raw corn starch, 0.08 parts of natural polymer modifier, and 70 parts of water into a reaction kettle with a stirrer and a thermometer, raise the temperature to 90°C, and keep the temperature for 2 hours to obtain the natural polymer. Emulsifier A1.

[0081] (2) Preparation of environment-friendly cationic polyacrylate

[0082] Add 90 parts of the above-mentioned natural polymer emulsifier into a reaction kettle with a stirrer and a thermometer, raise the temperature to 85°C, stir evenly, and continuously dropwise add initiator A, that is, 35 parts of 5% hydrogen peroxide aqueous solution within 3.5 hours , 0.1 part of molecular weight regulator dodecanethiol and mixed monomers, the mixed monomers are composed of 30 parts of styrene as hard monomer, 15 parts of isobutyl methacrylate, 15 parts of butyl acrylate as soft monomer, cationic 3 parts of diallyl ammonium chloride ...

Embodiment 2~5

[0084] (1) Synthesis of natural polymer emulsifier

[0085] The natural polymer emulsifiers A2-A5 were prepared according to the synthesis step (1) of Example 1 by using different dosages of the natural polymer emulsifier components in Table 1.

Embodiment 1-5

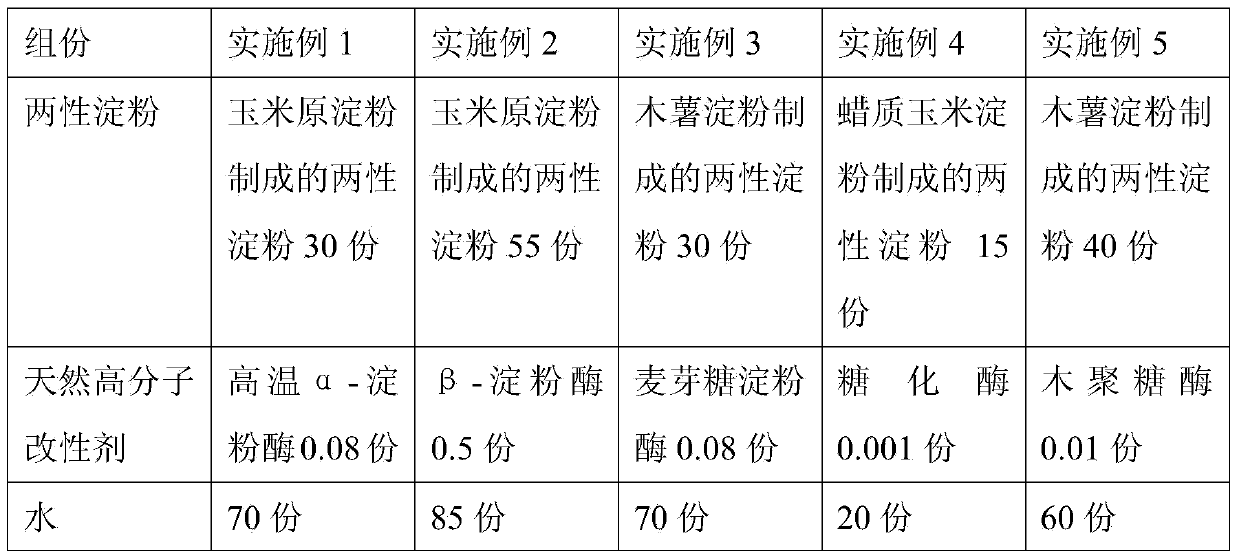

[0086] The synthetic embodiment 1-5 component weight parts of table 1 natural macromolecule emulsifier

[0087]

[0088] (2) Preparation of environment-friendly cationic polyacrylate

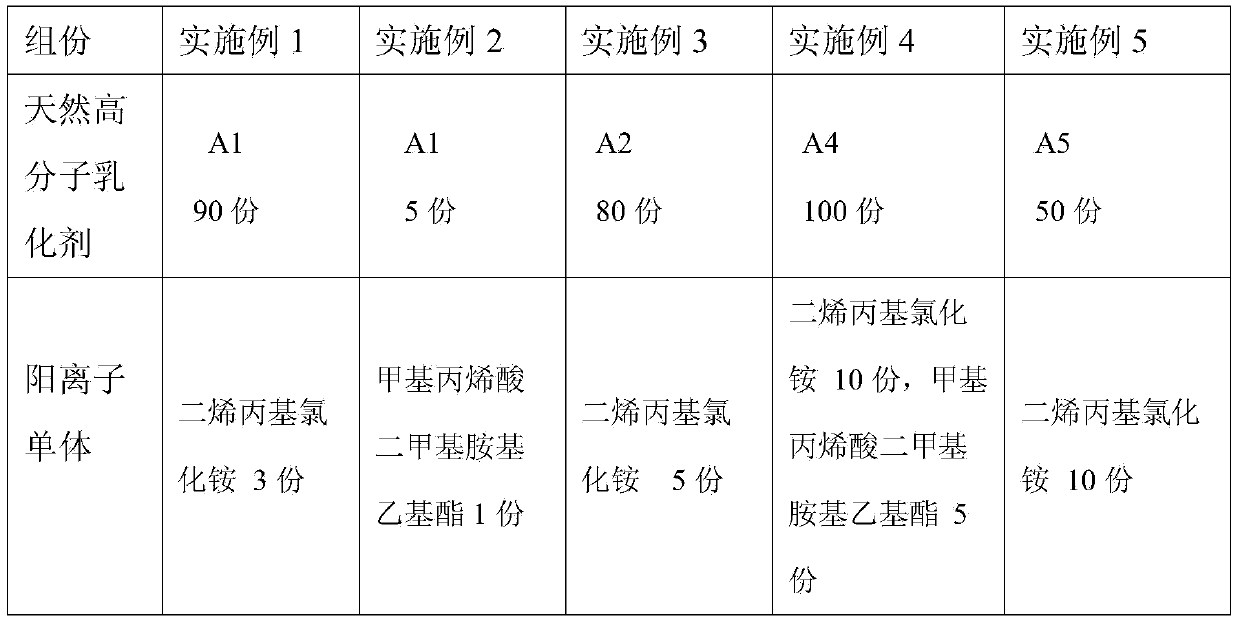

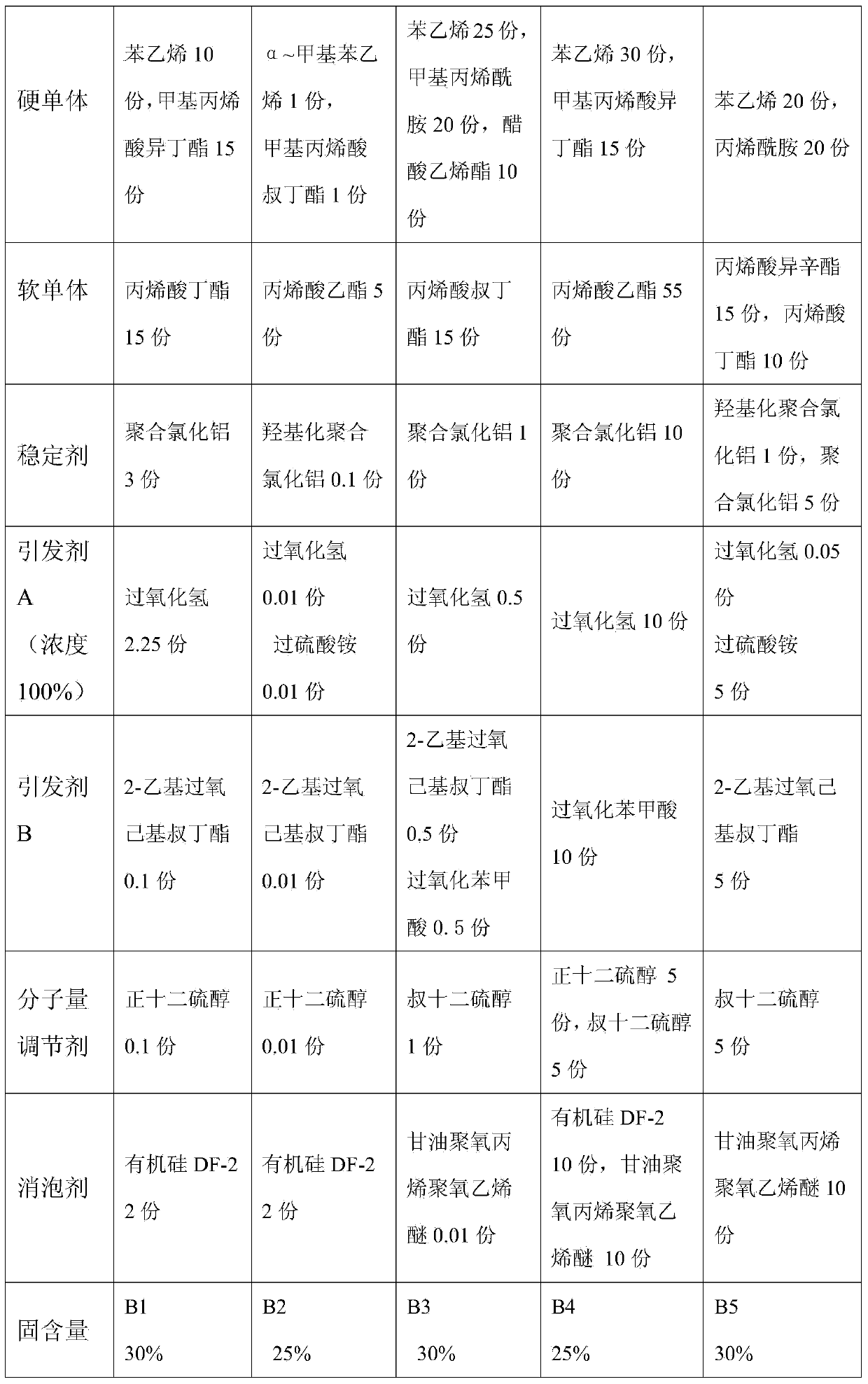

[0089] Utilize the natural macromolecular emulsifier A1~A5 that embodiment 1~5 synthesizes, according to the preparation process of embodiment 1 (2) the preparation of environment-friendly cationic polyacrylate, adopt the preparation of each component of table 2 environment-friendly cationic polyacrylate parts by weight to prepare environment-friendly cationic polyacrylates B2-B5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com