Inorganic mineral water treatment agent and preparation method thereof

A water treatment agent and inorganic mineral technology, applied in the direction of adsorption water/sewage treatment, chemical instruments and methods, other chemical processes, etc., can solve the problems of high production cost, complicated process, environmental pollution, etc., and achieve low cost and excellent preparation process Simple, Environmentally Friendly Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

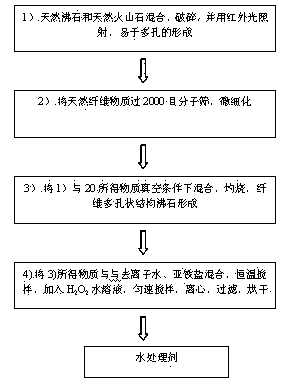

[0030] 1) Mix and crush 10KG faujasite and 5KG red volcanic stone to a particle size of 40 μm, soak in ethylenediaminetetraacetic acid for 3 hours, wash with hydrochloric acid with a concentration of 6M / L, heat and reflux for 8 hours, and then wash with distilled water. Dry at 150°C for 24 hours, and irradiate with infrared light with a wavelength of 750nm for 6 hours, which is conducive to the formation of pores;

[0031] 2) Fully micronize 2KG dry straw, pass through a 2000-mesh molecular sieve, and the length of the fiber strip is 30 μm;

[0032] 3) Mix the material obtained in 1) and 2) uniformly under the vacuum condition of 2.5MPa, and calcinate in a muffle furnace at 800°C for 5 hours, so that the material obtained in 1) forms a fibrous porous structure, and the fibrous porous zeolite matrix is formed;

[0033] 4) Add the substance in 3) into deionized water whose volume is 1.5 times the total volume of the substance in step 3), and then add 0.75KGFeSO 4 , stirred an...

Embodiment 2

[0037] 1) Mix and crush 5KG chabazite and 2.5KG red volcanic stone to a particle size of 40 μm, soak in ethylenediaminetetraacetic acid for 3 hours, wash with hydrochloric acid with a concentration of 6M / L, heat and reflux for 8 hours, and then wash with distilled water. Dry at 150°C for 24 hours, and irradiate with infrared light with a wavelength of 750nm for 6 hours, which is conducive to the formation of pores;

[0038] 2) Fully micronize 2KG dry sugarcane stems, pass through 2000 mesh molecular sieves, and the length of the fiber strips is 35 μm;

[0039] 3) Mix the material obtained in 1) and 2) uniformly under the vacuum condition of 2.5MPa, and calcinate in a muffle furnace at 800°C for 5 hours, so that the material obtained in 1) forms a fibrous porous structure, and the fibrous porous zeolite matrix is formed;

[0040] 4) Add the substance in 3) into deionized water whose volume is 0.9 times the total volume of the substance in step 3), and then add 0.45KGFeSO 4 ,...

Embodiment 3

[0044] 1) Mix and crush 6KG sodium zeolite and 3KG red volcanic stone to a particle size of 40 μm, soak in ethylenediaminetetraacetic acid for 3 hours, wash with hydrochloric acid with a concentration of 6M / L, heat and reflux for 8 hours, and then wash with distilled water. Dry at ℃ for 24 hours, and irradiate with infrared light with a wavelength of 750nm for 6 hours, which is conducive to the formation of pores;

[0045] 2) Fully micronize 2KG dry sugarcane stems, pass through 2000 mesh molecular sieves, and the length of the fiber strips is 35 μm;

[0046] 3) Mix the material obtained in 1) and 2) uniformly under the vacuum condition of 2.5MPa, and calcinate in a muffle furnace at 800°C for 5 hours, so that the material obtained in 1) forms a fibrous porous structure, and the fibrous porous zeolite matrix is formed;

[0047] 4) Add the substance in 3) into deionized water whose volume is 0.8 times the total volume of the substance in step 3), and then add 1.8KGFeSO 4 , s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com