Preparation method of bagasse pith nanometer cellulose-based composite water-retaining agent

A nanocellulose and water-retaining agent technology, applied in chemical instruments and methods, fertilizer mixtures, applications, etc., can solve the problems of increased number of agricultural operations and costs, general water absorption capacity, etc., and achieve good biodegradability, low price, good effect of tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

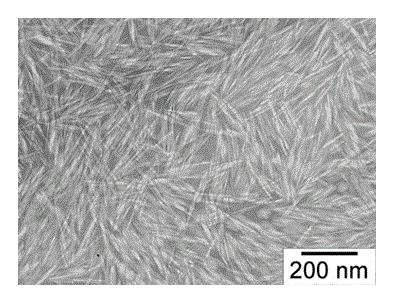

Image

Examples

Embodiment 1

[0033] Example 1: The preparation method of the cane pith nanocellulose-based composite water-retaining agent suitable for acidic soil is as follows:

[0034] (1) The preparation process of cane pith

[0035] The bagasse is air-dried to control the moisture content to be 7%, and then the air-dried material is screened by a sieve of 80-100 meshes to be qualified cane pith raw materials.

[0036] (2) Extraction of cellulose from cane pith parenchyma cells

[0037] Use hydrogen peroxide and glacial acetic acid mixture to extract cellulose from qualified cane pith raw materials, wherein the mass percentage concentration is 30% hydrogen peroxide and glacial acetic acid are mixed in a volume ratio of 1:3 to obtain hydrogen peroxide and ice Acetic acid mixture, the mass percentage concentration of cane pith raw material in the mixture is 8%, and then treated at 60 ° C for 48 hours. After the reaction is completed, the material is deionized and washed to neutrality and air-dried to...

Embodiment 2

[0054] Example 2: The preparation method of the cane pith nanocellulose-based composite water-retaining agent suitable for acidic soil is as follows:

[0055] (1) The preparation process of cane pith

[0056] The bagasse is air-dried to control the moisture content to be 10%, and then the air-dried material is screened by a 150-250 mesh sieve to obtain qualified cane pith raw materials.

[0057] (2) Extraction of cellulose from cane pith parenchyma cells

[0058] Use hydrogen peroxide and glacial acetic acid mixture to extract cellulose from qualified cane pith raw materials, wherein the mass percentage concentration is 32% hydrogen peroxide and glacial acetic acid are mixed in a volume ratio of 1:1 to obtain hydrogen peroxide and ice Acetic acid mixed solution, the mass percentage concentration of cane pith raw material in the mixed solution is 10%, and then treated at 80 ° C for 36 hours. After the reaction is completed, the material is deionized and washed to neutrality ...

Embodiment 3

[0075] Example 3: The preparation method of the cane pith nanocellulose-based composite water-retaining agent suitable for acid soil, the specific operations are as follows:

[0076] (1) The preparation process of cane pith

[0077] The bagasse is air-dried to control the moisture content to be 20%, and then the air-dried material is screened by a 300-350 mesh sieve to be a qualified cane pith raw material.

[0078] (2) Extraction of cellulose from cane pith parenchyma cells

[0079] Use hydrogen peroxide and glacial acetic acid mixture to extract cellulose from qualified cane pith raw materials, wherein the mass percentage concentration of 35% hydrogen peroxide and glacial acetic acid is mixed in a volume ratio of 3:1 to obtain hydrogen peroxide and ice Acetic acid mixture, the mass percentage concentration of cane pith raw material in the mixture is 15%, and then treated at 100 ° C for 12 hours. After the reaction is completed, the material is deionized and washed to neut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com