Preparation method for wool keratin regenerated cellulose fiber

A wool keratin and regenerated cellulose technology is applied in the field of preparation of wool keratin regenerated cellulose fibers, can solve the problems of affecting fibrin content and fiber strength, small protein molecular weight, low protein yield, etc., and achieves increased cross-linking Fixing effect, overcoming the effect of low protein content and increasing protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

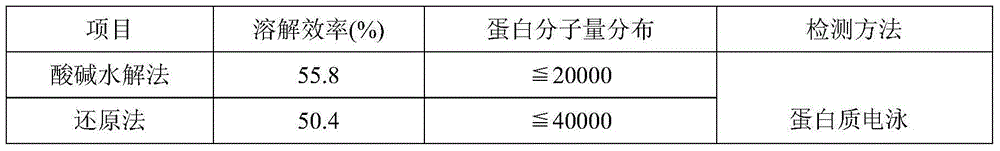

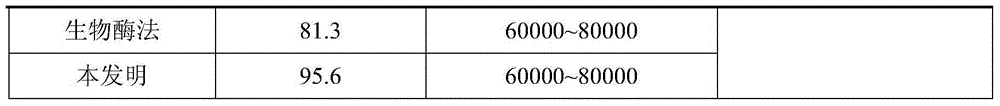

[0023] The keratin solution prepared by comparative chemical method, biological enzyme method and the present invention.

[0024] The chemical method mainly breaks the protein macromolecular chain through acid-base hydrolysis or breaks the disulfide bond in (between) the protein macromolecules through redox to achieve the purpose of dissolution. There are mainly acid-base hydrolysis, oxidation and reduction methods, etc.

[0025] The biological enzyme method is to use the specificity of keratinase to degrade keratin to obtain a keratin solution.

[0026] The invention adopts the combination method of biological enzymatic method and reduction method, adding reducing agent to open the disulfide bond between protein molecules (internal), and then adding keratinase to prepare keratin solution.

[0027]

[0028]

[0029] It can be seen from the above table that the keratin solution prepared by the present invention not only has high dissolution efficiency, but also has relat...

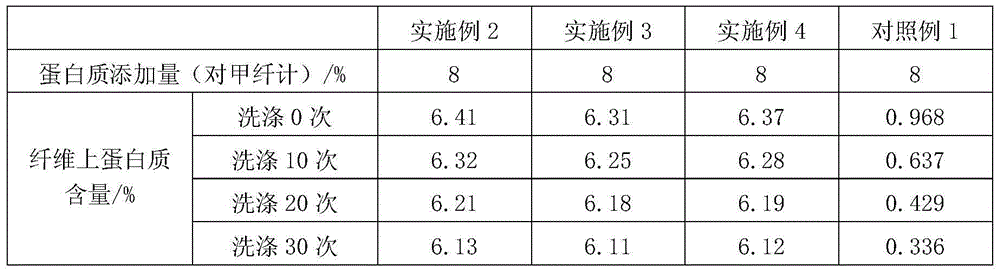

Embodiment 2

[0031] Preparation of viscose solution: use cotton pulp with a degree of polymerization of 500 and a mass content of cellulose of 93.5% to prepare spinning viscose solution through the processes of impregnation, pressing, crushing, aging, yellowing, continuous dissolution, filtration, and deaeration. . The obtained methyl fiber mass content 8.9%, NaOH mass content 6.2%, viscosity (falling ball method) 45s, maturity (10%NH 4 Cl) 8.4ml is the viscose solution for use.

[0032] Falling ball method: the time required for a 2mm steel ball to fall 20cm from the viscose solution.

[0033] Preparation of keratin solution: In the reactor, prepare a keratin solution with a mass fraction of 8% with distilled water, first add NaHSO that accounts for 1% of wool protein powder to the solution 3 , and then add keratinase accounting for 1% of the mass fraction of wool protein powder to the reaction kettle solution, adjust the pH of the solution to 7.5-8.0 with NaOH, then raise the temperatu...

Embodiment 3

[0040] Preparation of viscose solution: use cotton pulp with a degree of polymerization of 520 and a mass content of cellulose of 92.5% to prepare spinning viscose solution through the processes of impregnation, pressing, crushing, aging, yellowing, continuous dissolution, filtration, and defoaming. . The obtained methyl fiber mass content 8.7%, NaOH mass content 6.3%, viscosity (falling ball method) 63s, maturity (10%NH 4 Cl) 8.6ml is the viscose solution for use.

[0041] Preparation of pre-crosslinked gluten protein solution: in the reaction kettle, prepare a 10% wool protein powder solution with a mass fraction of distilled water, first add 1% Na 2 SO 3 , and then add keratinase accounting for 0.5% of the mass fraction of wool protein powder to the reaction kettle solution, adjust the pH of the solution to 7.5-8.0 with NaOH, then raise the temperature of the solution to 50-60° C., and keep it warm for 1 hour. Add 0.5% sodium hexametaphosphate and 0.5% monoglyceride stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com