Chitosan/polyvinyl alcohol/ferroferric oxide composite magnetic particle as well as preparation and application thereof

A technology of composite magnetic particles and ferroferric oxide, which is applied in the fields of alkali metal compounds, water/sludge/sewage treatment, alkali metal oxides/hydroxides, etc., which can solve the problems of high consumption, high cost, and limited application range, etc. problems, to achieve the effect of high utilization rate of raw materials, simplified steps, and controllable particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

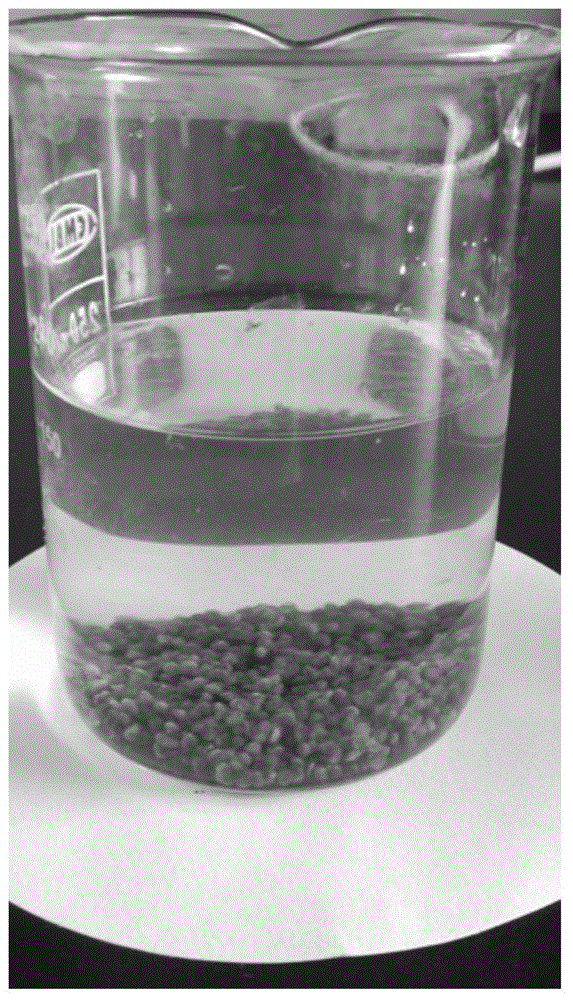

Embodiment 1

[0036] Weigh 2.0g of chitosan powder and dissolve it in 40mL of distilled water, add dropwise acetic acid to adjust the pH of the solution to 5-6, stir and dissolve at room temperature; weigh 7.5g of polyvinyl alcohol powder and dissolve it in 100mL of distilled water at 80°C for 50 minutes, and cool to room temperature; mix the chitosan solution and the polyvinyl alcohol solution, and mechanically stir evenly; at the same time, weigh 0.5g ferric oxide powder and add it to the above blend solution, and disperse ultrasonically for 10 minutes to make the ferric oxide disperse evenly; into 100mL1mol / L NaOH solution, the droplets solidified into spherical particles immediately, and stood for 5 minutes; transferred the spherical particles to distilled water for soaking and washing twice, and then transferred to absolute ethanol solution to swell for 30 minutes; after taking them out, dry them naturally, Chitosan / polyvinyl alcohol / ferric oxide ternary composite magnetic particles can...

Embodiment 2

[0039] Weigh 5.0g of chitosan powder and dissolve in 100mL of distilled water, add dropwise acetic acid to adjust the pH value of the solution to 5-6, stir and dissolve at room temperature; weigh 5.0g of polyvinyl alcohol powder and dissolve it in 100mL of distilled water at 75°C for 40 minutes, and cool to room temperature; mix the chitosan solution and the polyvinyl alcohol solution, and mechanically stir evenly; simultaneously weigh 1.2g of Fe3O4 powder and add it to the blend solution, and ultrasonically disperse for 10min to make the Fe3O4 disperse evenly; into 100mL1mol / L NaOH solution, the droplets solidified into spherical particles immediately, and stood for 10 minutes; transferred the spherical particles to distilled water for soaking and washing twice, and then transferred to absolute ethanol solution to swell for 30 minutes; after taking them out, dry them naturally, Chitosan / polyvinyl alcohol / ferric oxide ternary composite magnetic particles can be obtained.

[00...

Embodiment 3

[0042] Weigh 6.0g of chitosan powder and dissolve it in 110mL of distilled water, add dropwise acetic acid to adjust the pH of the solution to 5-6, stir and dissolve at room temperature; weigh 2.5g of polyvinyl alcohol powder and dissolve it in 30mL of distilled water at 70°C for 20 minutes, and cool to room temperature; mix the chitosan solution and the polyvinyl alcohol solution, and mechanically stir evenly; at the same time, weigh 1.4g ferric oxide powder and add it to the blend solution, and ultrasonically disperse it for 10 minutes to disperse the ferric oxide uniformly; Put it into 100mL1mol / L NaOH solution, the droplets solidify into spherical particles immediately, let stand for 20min; Polysaccharide / polyvinyl alcohol / ferric oxide ternary composite magnetic particles.

[0043] The resulting particles were then observed with a scanning electron microscope (see Figure 5 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com