A kind of preparation method of zrb2/cu composite material

A composite material and powder technology, applied in the field of preparation of ZrB2/Cu composite material, can solve problems such as electrode material loss, and achieve the effects of improving structure, good social and economic benefits, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] ZrB 2 The preparation method of / Cu composite material, comprises the following steps:

[0027] (1) ZrB 2 Powder nickel plating treatment: take ZrB 2 Powder, pretreated in the order of pickling, sensitization, and activation, and then electroless nickel plating; ZrB after nickel plating 2 The powder is dried under vacuum and ready for use;

[0028] The pickling is treated with HCl, that is, ZrB 2 The powder was placed in a HCl solution with a volume fraction of 37%, stirred at a low speed for 30 minutes, and then pickled; the pickled powder was ultrasonically cleaned in absolute ethanol for 10 minutes, and then vacuum-dried for 4 hours;

[0029] The sensitization uses SnCl 2 Solution processing, specifically refers to the ZrB after pickling and drying 2 powder placed in SnCl 2 -Stirring at low speed in HCl solution for 30 minutes for sensitization treatment; the sensitization SnCl 2 -SnCl in HCl solution treatment 2 2H 2 The concentration of O is 0.1mol / L, and...

Embodiment 2

[0039] This embodiment prepares ZrB 2 / Cu composite material, the steps are the same as in Example 1, only adjusting ZrB in step (2) 2 And the volume ratio of Cu, the volume fraction of Cu is 60%, that is, ZrB after nickel plating 2 The powder weight is 20g, and the Cu powder is 40g; in the adjustment step (3), the pressure during hot-press sintering is 20MPa, the sintering temperature is 900°C, the heating rate is 100°C / min, and the holding time is 30min.

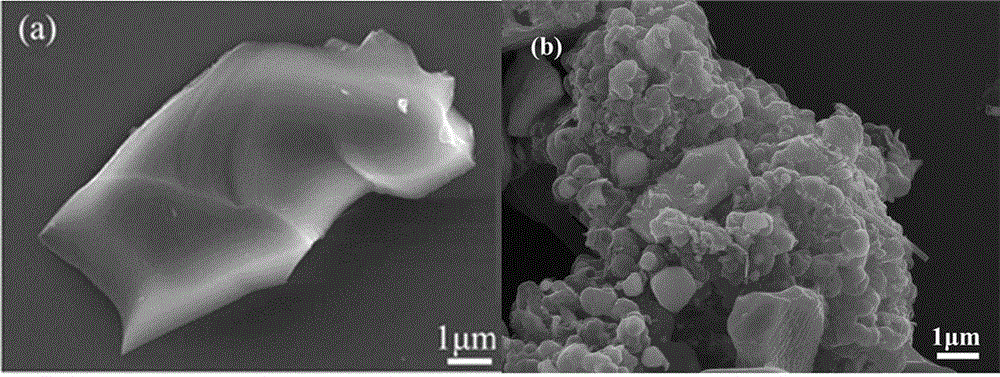

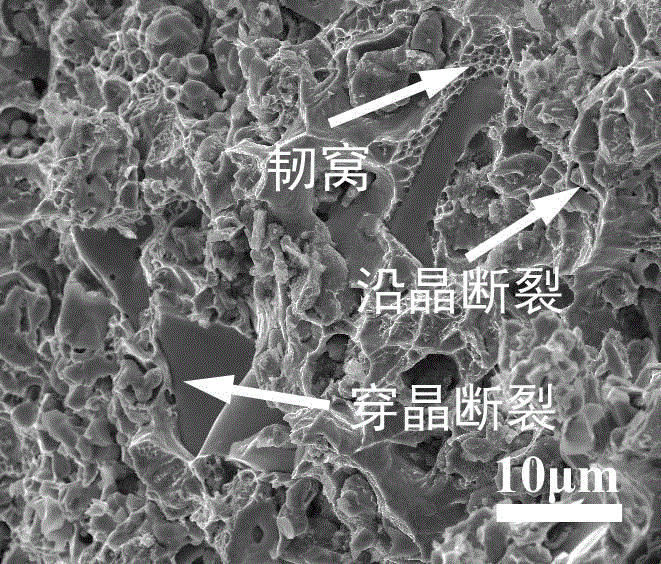

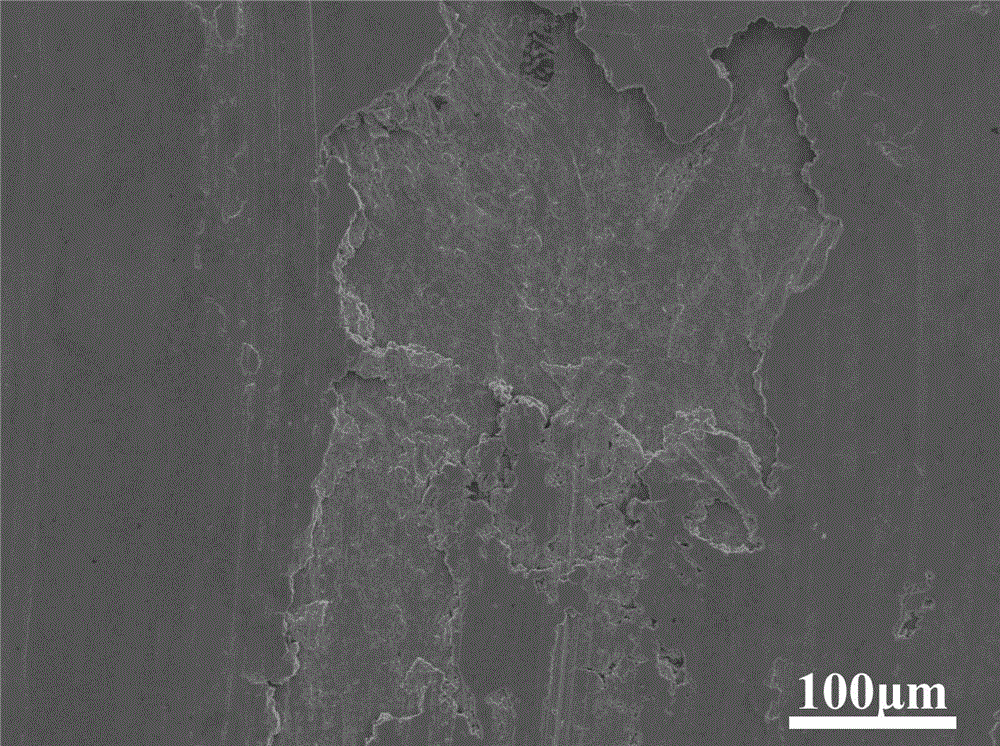

[0040] As-prepared ZrB 2 SEM image of the cross section of / Cu composite material figure 2 It can be seen from the figure that the structure of the material sample is dense, showing a fracture model combining ductile fracture and brittle fracture. image 3 Sintered ZrB 2 The SEM image of the worn surface of the / Cu composite material sample shows that the surface of the sample shows the characteristics of layered peeling and adhesive wear, and there are slight grooves on the surface.

Embodiment 3

[0042] This embodiment prepares ZrB 2 / Cu composite material, the steps are the same as in Example 1, only adjusting ZrB in step (2) 2 And the volume ratio of Cu, the volume fraction of Cu is 70%, that is, ZrB after nickel plating 2 The powder weight is 15g, and the Cu powder is 50g; in the adjustment step (3), the pressure during hot-press sintering is 30MPa, the sintering temperature is 900°C, the heating rate is 100°C / min, and the holding time is 45min.

[0043] The ZrB prepared in this embodiment 2 / Cu composite material for performance measurement, its bending strength is 475MPa, thermal diffusivity is 0.7781m 2 ·s, the thermal conductivity is 270W / (m·K), the resistivity is 2.1μΩ·cm, and the electrical conductivity is 0.48×106S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com