Crease-resistant finishing method for point-like crosslinked fabric based on spraying method

A technology of anti-wrinkle finishing and anti-wrinkle finishing agent, which is applied in the field of textile finishing, which can solve the problems of non-compliance with environmental protection and economical saving, adverse effects on clothing performance, and high liquid retention rate of fabrics, so as to achieve small equipment footprint and strong mobility , good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

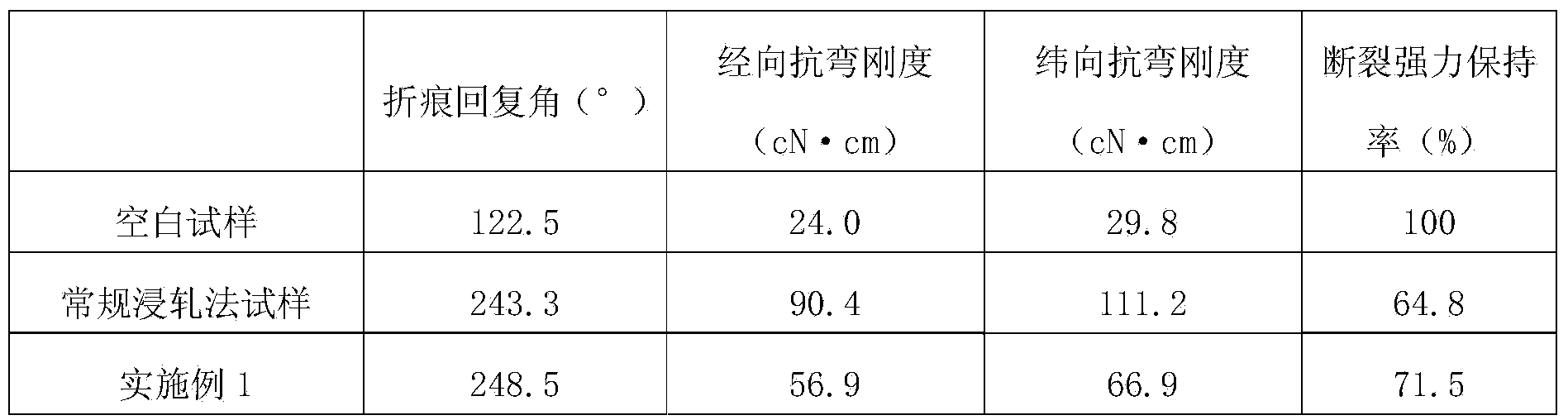

Embodiment 1

[0050] (1) 80-count pure cotton twill fabric, weight 122g / m 2 , pre-washed, desized, boiled, pre-shaped, surface impurities removed, then washed, dried, and shaped.

[0051] (2) Preparation of anti-wrinkle finishing agent working solution: per liter of water, mix 150g of glyoxal, 50g of magnesium chloride, 40g of ethylene glycol, 5g of dimethyl diallyl ammonium chloride, 2g of glacial acetic acid, 2g of penetrant, and 8g of potassium chloride , prepared at room temperature.

[0052] (3) Spraying process: 6 nozzles are densely arranged and fixed spraying device, two-phase flow atomization, finishing liquid droplet size 120-150μm, droplet spacing 110-130μm, spraying volume 55kg / h, transmission speed 40m / min. Apply an electrostatic field with a voltage of 1000V. The acceptability of the fabric to the working solution of the finishing agent is 13.8g / m 2 , fabric dry weight gain 1.3g / m 2 .

[0053] (4) Pre-baking process: the pre-baking temperature is 90°C, and the pre-baking...

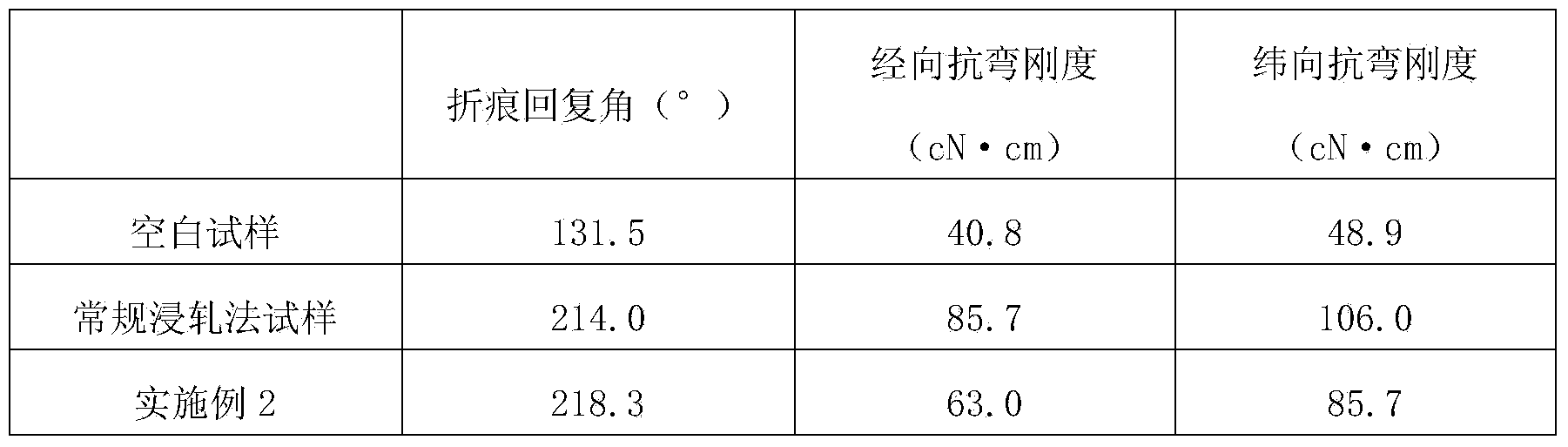

Embodiment 2

[0058] (1) Viscose twill fabric, weight 124.4g / m 2 , pre-washed, boiled, and pre-shaped to remove surface impurities, then washed, dried, and shaped.

[0059] (2) Preparation of anti-wrinkle finishing agent working solution: every liter of water is equipped with 50 g of citric acid, 30 g of butane tetracarboxylic acid, 20 g of maleic anhydride, 80 g of sodium hypophosphite, 6 g of ammonium persulfate, 1 g of triethylene glycol dimethacrylate, 20g of triethanolamine, 5g of 1,1′,1″-trimethylolpropane, 1g of penetrant, and 5g of sodium chloride were prepared at room temperature.

[0060] (3) Spraying process: 8 nozzles are densely arranged and fixed spraying device, three-phase flow atomization, finishing liquid droplet size 40-60μm, droplet spacing 30-40μm, spraying volume 40kg / h, transmission speed 30m / min. The acceptance amount of the fabric to the working solution of the finishing agent is 13.5g / m 2 , fabric dry weight gain 1.6g / m 2 .

[0061] (4) Pre-drying process: pre...

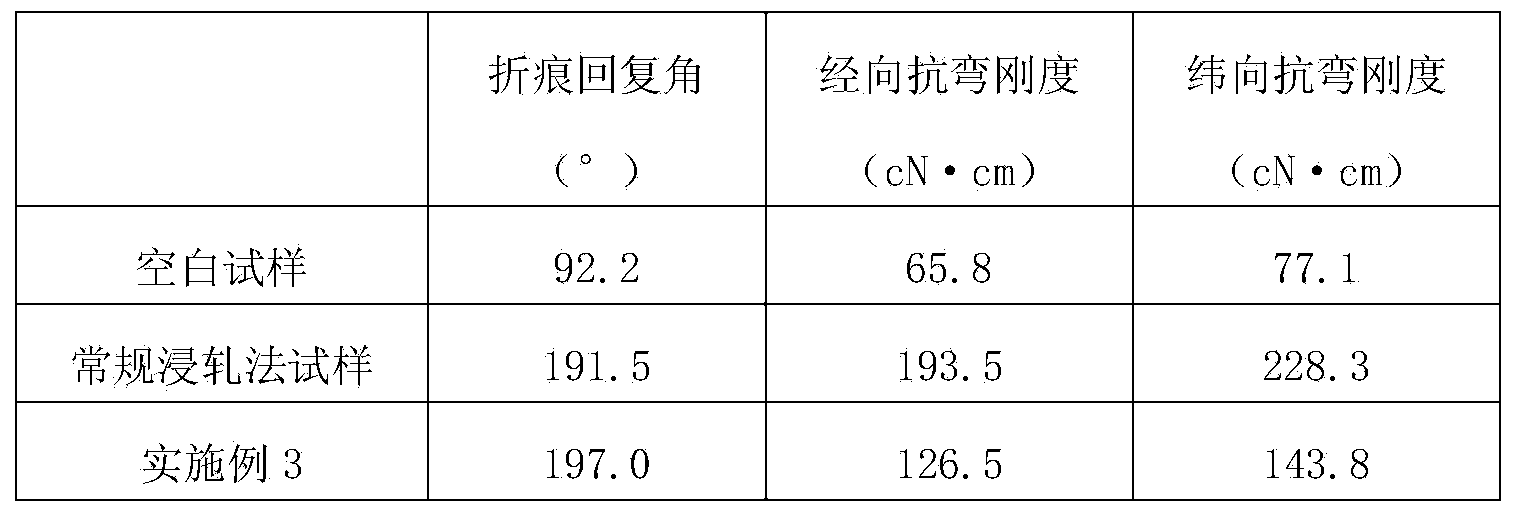

Embodiment 3

[0066] (1) Linen plain weave fabric, weight 130g / m 2 , pre-washed, boiled, and pre-shaped to remove surface impurities, then washed, dried, and shaped.

[0067] (2) Preparation of anti-wrinkle finishing agent working solution: per liter of water, add 100 g of etherified 2D resin, 35 g of magnesium chloride, 1 g of triethylene glycol dimethacrylate, 1 g of glacial acetic acid, 1 g of penetrant, and 5 g of potassium chloride, and prepare at room temperature.

[0068] (3) Spraying process: single-nozzle moving spraying device, centrifugal atomization, finishing liquid droplet size 150-180μm, droplet spacing 120-150μm, spraying volume 15kg / h, transmission speed 5m / min . The acceptance amount of the fabric to the working solution of the finishing agent is 28.7g / m 2 , fabric dry weight gain 0.87g / m 2 .

[0069] (4) Pre-baking process: the pre-baking temperature is 90°C, and the pre-baking time is 10 minutes.

[0070] (5) Baking process: the baking temperature is 140° C., and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com