Chromium-copper binary composite oxide catalyst and preparation method thereof

A binary compound and oxide technology, applied in the field of catalysis, can solve the problems of anti-sintering to be improved, and achieve the effect of low price, wide source and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

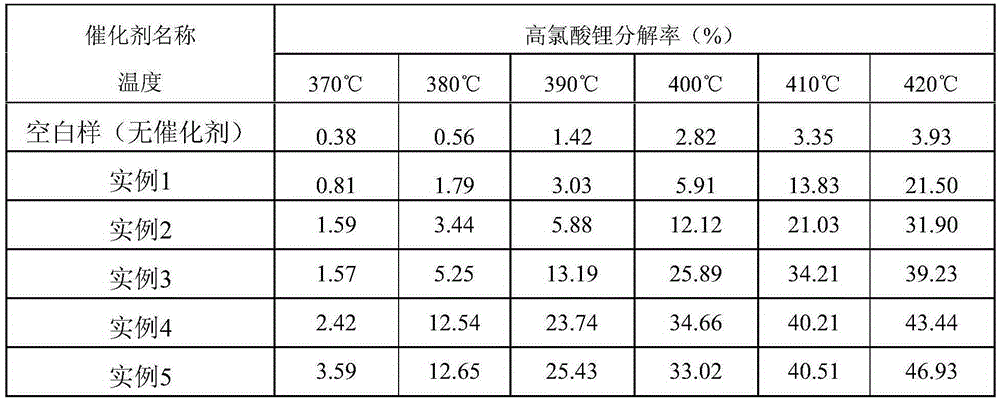

[0025] The preparation method of chromium-copper binary composite oxide catalyst, concrete steps are as follows:

[0026] (1) Determine the general formula Cr of the chromium-copper binary composite oxide catalyst x Cu 1-x o 1+0.5x The value of x in the middle, and the value range of x is 0.2~0.8, then weigh Cr(NO 3 ) 3 9H 2 O and Cu(NO 3 ) 2 ·3H 2 0, add deionized water to dissolve and obtain metal ion solution;

[0027] (2) According to the molar ratio Cr x Cu 1-x o 1+0.5x :C 12 h 22 o 11 For a ratio of 1:2, weigh sucrose C 12 h 22 o 11 Add in the metal ion solution that step (1) makes, and stir to dissolve sucrose to obtain solution, Cr in the solution x Cu 1-x o 1+0.5x The molar concentration range of sucrose is 0.05-0.2mol / L, and the molar concentration range of sucrose is 0.1-0.4mol / L, and then the obtained solution is heated in a water bath at 70-90°C, and stirred until it evaporates to dryness to form a gel;

[0028] (3) drying the gel prepared in s...

Embodiment 1

[0032] Weigh Cr(NO 3 ) 3 9H 2 O was dissolved in deionized water, and then according to the molar ratio Cr(NO 3 ) 3 9H 2 O: C 12 h 22 o 11 Add sucrose C to the solution in a ratio of 1:2 12 h 22 o 11 , Cr(NO 3 ) 3 9H 2 The molar concentration of O is 0.05 mol / L, and the molar concentration of sucrose is 0.1 mol / L. The solution was heated and stirred in a water bath at 70°C until it was evaporated to dryness, then dried at 110°C for 12 hours, the mixture was ground into a fine powder of about 200 mesh, heated to 400°C at a heating rate of 5°C / min, After carbonization for 3 hours, the furnace was cooled to room temperature; then the temperature was raised to 900 °C at a rate of 5 °C / min, calcined in air atmosphere for 4 hours, and the furnace was cooled to room temperature to prepare a metal oxide catalyst.

Embodiment 2

[0034] Weigh Cu(NO3 ) 2 ·3H 2 O was dissolved in deionized water, and then according to the molar ratio Cu(NO 3 ) 2 ·3H 2 O: C 12 h 22 o 12 Add sucrose C to the solution in a ratio of 1:2 12 h 22 o 11 , Cu(NO 3 ) 2 ·3H 2 The molar concentration of O is 0.05 mol / L, and the molar concentration of sucrose is 0.1 mol / L. The solution was heated and stirred in a water bath at 70°C until it was evaporated to dryness, then dried at 110°C for 12 hours, the mixture was ground into a fine powder of about 200 mesh, heated to 400°C at a heating rate of 5°C / min, After carbonization for 3 hours, the furnace was cooled to room temperature; then the temperature was raised to 900 °C at a rate of 5 °C / min, calcined in air atmosphere for 4 hours, and the furnace was cooled to room temperature to prepare a metal oxide catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com