Polyurethane adhesive and preparation method thereof

A polyurethane adhesive and amine catalyst technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of prolonged curing time, short pot life, affecting later operation, etc., and achieve excellent yellowing resistance. , good heat resistance, high environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

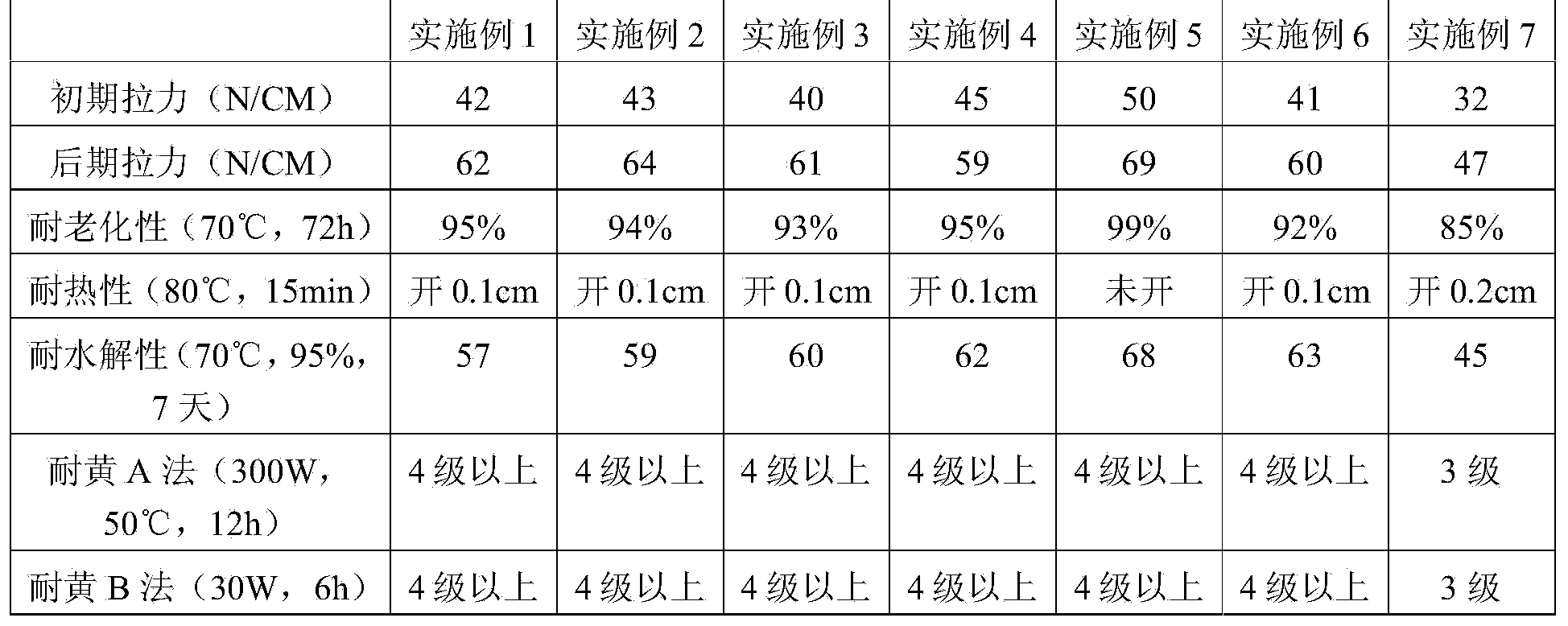

Examples

Embodiment 1

[0019] Polyurethane adhesive, including by weight: 100 parts of diphenylmethane diisocyanate, 20 parts of styrene grafted polyether polyol, 30 parts of bisphenol A epoxy resin, 5 parts of methyl p-toluenesulfonate, 3 parts of polypropylene glycol 1 part of polyoxypropylene pentaerythritol ester, 2 parts of triethylenediamine, 0.5 part of isophorone diamine, 0.2 part of zeolite, 0.4 part of castor oil, zinc N-ethyl-N-phenyldithiocarbamate 0.1 part, 0.3 part of resorcinol, 0.2 part of triphenylphosphine, 1 part of silane coupling agent KH-5501, 2 parts of sodium lauryl sulfate.

[0020] First pour diphenylmethane diisocyanate, amine catalyst, epoxy resin, methyl p-toluenesulfonate, polypropylene glycol and polyoxypropylene pentaerythritol ester into the stirring tank, then add zeolite and stir well, heat the stirring tank and pump Vacuum until the vacuum degree is -0.08Mpa. When the temperature reaches 100°C, continue to maintain the vacuum for 2h, add resorcinol and triphenylph...

Embodiment 2

[0022] The polyurethane adhesive comprises in parts by weight: 115 parts of diphenylmethane diisocyanate, 23 parts of styrene grafted polyether polyol, 35 parts of bisphenol A epoxy resin, 7 parts of methyl p-toluenesulfonate, 5 parts of polypropylene glycol Parts, 2 parts of polyoxypropylene pentaerythritol ester, 3 parts of tetraethylenetriamine, 0.8 part of isophorone diamine, 0.3 part of zeolite, 0.6 part of castor oil, zinc N-ethyl-N-phenyldithiocarbamate 0.2 parts, 0.5 parts of resorcinol, 0.4 parts of triphenylphosphine, 2 parts of silane coupling agent KH-5602, 3 parts of sodium lauryl sulfate.

[0023] First pour diphenylmethane diisocyanate, amine catalyst, epoxy resin, methyl p-toluenesulfonate, polypropylene glycol and polyoxypropylene pentaerythritol ester into the stirring tank, then add zeolite and stir well, heat the stirring tank and pump Vacuum until the vacuum degree is -0.1Mpa. When the temperature reaches 120°C, continue to maintain the vacuum for 0.5h, ad...

Embodiment 3

[0025] Polyurethane adhesive, including by weight: 135 parts of diphenylmethane diisocyanate, 25 parts of styrene grafted polyether polyols, 42 parts of bisphenol A epoxy resin, 8 parts of methyl p-toluenesulfonate, 7 parts of polypropylene glycol 3 parts of polyoxypropylene pentaerythritol ester, 5 parts of pentaethylenetetramine, 1.5 parts of isophorone diamine, 0.4 parts of zeolite, 0.9 parts of castor oil, zinc N-ethyl-N-phenyldithiocarbamate 0.3 parts, 0.8 parts of resorcinol, 0.6 parts of triphenylphosphine, 2 parts of silane coupling agent, 4 parts of sodium lauryl sulfate.

[0026] The above-mentioned silane coupling agent is a mixture of KH-550 and KH-560, and its weight ratio is 3:7.

[0027] First pour diphenylmethane diisocyanate, amine catalyst, epoxy resin, methyl p-toluenesulfonate, polypropylene glycol and polyoxypropylene pentaerythritol ester into the stirring tank, then add zeolite and stir well, heat the stirring tank and pump Vacuum until the vacuum degre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com