Anti-reactive dye stain

A reactive dye and staining technology, which is applied in the fields of textile auxiliaries and fine chemicals, can solve the problems affecting color fastness to washing, color fastness to rubbing, poor product quality stability, and long debugging process, so as to improve the anti-staining effect Color effect, improve product quality, shorten the effect of color adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

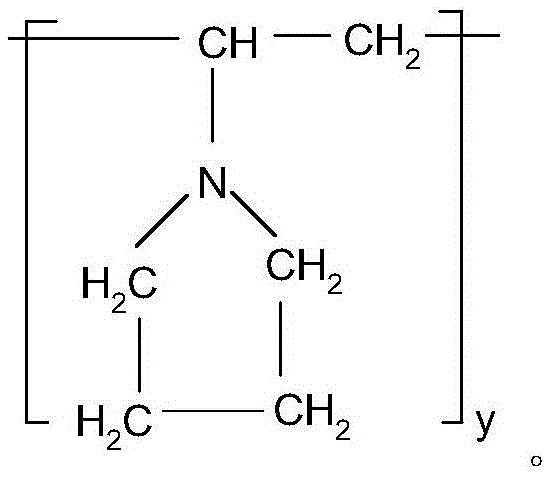

[0018] The anti-reactive dye staining agent is characterized in that: by mass percentage, it includes: 2-10% of alkyl ammonium halide salt, 15-40% of polyvinylpyrrolidone, 10-20% of fatty amine polyoxyethylene ether, alkylphenol and Ethylene oxide condensate is 10-20%, and the rest is water. Alkyl ammonium halide salt is alkyl C8-C16 ammonium halide salt. The halogen of alkyl ammonium halide salt is chlorine or bromine. The structural formula of polyvinylpyrrolidone is:

[0019] The viscosity-average molecular weight of polyvinylpyrrolidone is 8000-40000, and the structural formula of fatty amine polyoxyethylene ether is:

[0020] Wherein a is 10-16, and b is 5-25.

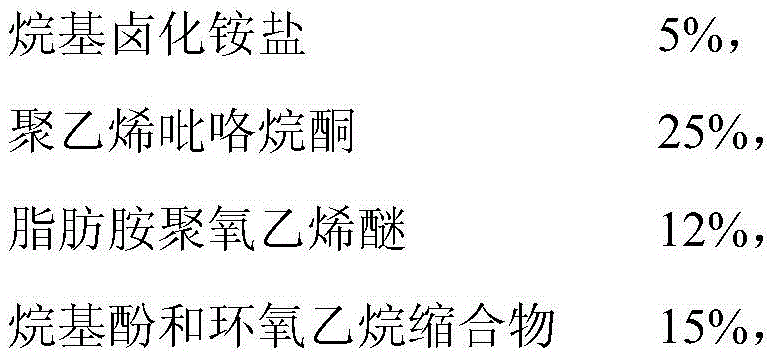

[0021] The formula for modified polyester fiber anti-reactive dye staining agent 1 is composed as follows by mass percentage:

[0022]

[0023] The rest is water.

[0024] Alkyl ammonium halide salts, polyvinylpyrrolidone, aliphatic amine polyoxyethylene ethers, and alkylphenol and ethylene oxide condensa...

Embodiment 2

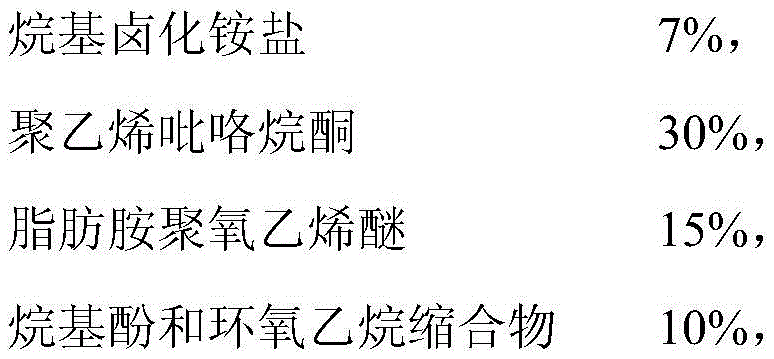

[0026] For modified polyester fiber anti-reactive dye staining agent 2 formula is composed as follows by mass percentage:

[0027]

[0028] The rest is water.

[0029] Alkyl ammonium halide salts, polyvinylpyrrolidone, aliphatic amine polyoxyethylene ethers, and alkylphenol and ethylene oxide condensates are commercially available conventional industrial products.

Embodiment 3

[0031] For modified polyester fiber anti-reactive dye staining agent 3 formula is composed as follows by mass percentage:

[0032]

[0033] The rest is water.

[0034] Alkyl ammonium halide salts, polyvinylpyrrolidone, aliphatic amine polyoxyethylene ethers, and alkylphenol and ethylene oxide condensates are commercially available conventional industrial products.

[0035] The anti-staining agent provided by the invention is used for dyeing modified polyester fiber / cotton fiber blended fabrics. The modified polyester fibers used in the examples of the present invention are cationic dyeable hollow polyester staple fibers. Polyester fiber is firstly treated with sodium hydroxide and hydrogen peroxide in the same bath, and then dyed with disperse dyes. Finally, it is dyed according to the conventional process of dyeing cotton fibers in the reactive dye laboratory. The color difference between samples before and after dyeing with reactive dyes is measured for the evaluation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com