Method for measuring content of tellurium in antimony and antimonous oxide

A technology for the determination of antimony trioxide and its determination method, which is applied in the preparation of test samples and the measurement of color/spectral characteristics, and can solve the problems of no tellurium determination method for antimony and antimony trioxide, and achieve fast determination speed and analysis efficiency High and accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

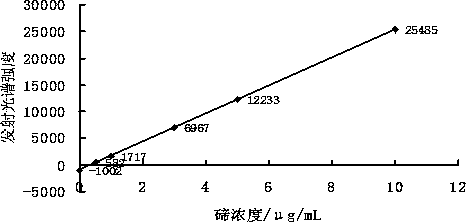

[0046] In this embodiment, it is determined by an inductively coupled plasma emission spectrometer.

[0047] (1) Sample handling

[0048] a. Antimony sample

[0049]Weigh 0.5005g of antimony sample and place it in a 100mL beaker, dissolve it with 5mL of aqua regia, add 2mL of sulfuric acid, 5mL of hydrobromic acid and heat it on a low-temperature electric furnace. Below 80°C; Add 1mL of hydrochloric acid and 5mL of hydrobromic acid, heat to 200°C-340°C until white smoke comes out, then cool to below 80°C. Repeatedly add 1mL of hydrochloric acid and 5mL of hydrobromic acid, heat to 200°C-340°C, emit white smoke (only residue remains at this time), and cool to room temperature. Add 2mL of hydrochloric acid to dissolve the residue at 95°C-100°C, transfer the solution into a 10mL volumetric flask, dilute with water to the mark, and mix well.

[0050] b. Antimony trioxide sample

[0051] Weigh 0.5010g of antimony trioxide sample into a 100mL beaker, dissolve it with 5mL of hydr...

Embodiment 2

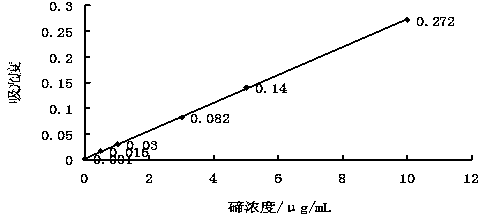

[0074] The present embodiment is determined by flame atomic absorption spectrometer.

[0075] (1) Sample handling

[0076] a. Antimony sample

[0077] Weigh 1.0008g of antimony sample and place it in a 100mL beaker, dissolve it with 5mL of aqua regia, add 2mL of sulfuric acid, 5mL of hydrobromic acid and heat it on a low-temperature electric furnace. Below 80°C; add 1mL hydrochloric acid, 5mL hydrobromic acid, heat to 200°C-340°C, until white smoke comes out, cool to below 80°C; add 1mL hydrochloric acid, 5mL hydrobromic acid repeatedly, heat to 200°C-340°C, Exhaust white smoke (only the residue remains at this time), cool to room temperature; add 2mL hydrochloric acid to dissolve the residue at 95°C-100°C, transfer the solution into a 10mL volumetric flask, dilute to the mark with water, and mix well.

[0078] b. Antimony trioxide sample

[0079] Weigh 1.0010g of antimony trioxide sample into a 100mL beaker, dissolve it with 5mL of hydrochloric acid, add 2mL of sulfuric ac...

Embodiment 3

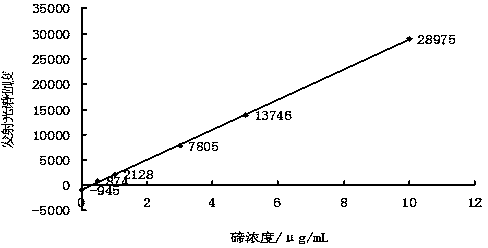

[0102] In this embodiment, it is measured by an inductively coupled plasma emission spectrometer.

[0103] (1) Sample handling

[0104] a. Antimony sample

[0105] Weigh 1.0011g of antimony sample and place it in a 100mL beaker, dissolve it with 5mL of aqua regia, add 2mL of sulfuric acid, 5mL of hydrobromic acid and heat it on a low-temperature electric furnace. Below 80°C. Add 1mL of hydrochloric acid and 5mL of hydrobromic acid, heat to 200°C to 340°C until white smoke comes out, and cool to 80°C. Repeatedly add 1mL of hydrochloric acid and 5mL of hydrobromic acid, heat to 200°C-340°C, emit white smoke (only residue remains at this time), and cool to room temperature. Add 2mL of hydrochloric acid to dissolve the residue at 95°C-100°C, transfer the solution into a 10mL volumetric flask, dilute with water to the mark, and mix well.

[0106] b. Antimony trioxide sample

[0107]Weigh 1.0015g of antimony trioxide sample into a 100mL beaker, dissolve it with 5mL of hydrochlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com