Preparing device and method for nanofiller capillary chromatography microcolumn

A technology for capillary chromatography and nano-filling, which is applied to a nano-filling capillary chromatographic micro-column preparation device and the field of preparation thereof, can solve the problems of long preparation period, expensive equipment required for preparation, complicated preparation process of nano-filling capillary chromatographic micro-column, and the like. Simple and efficient method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

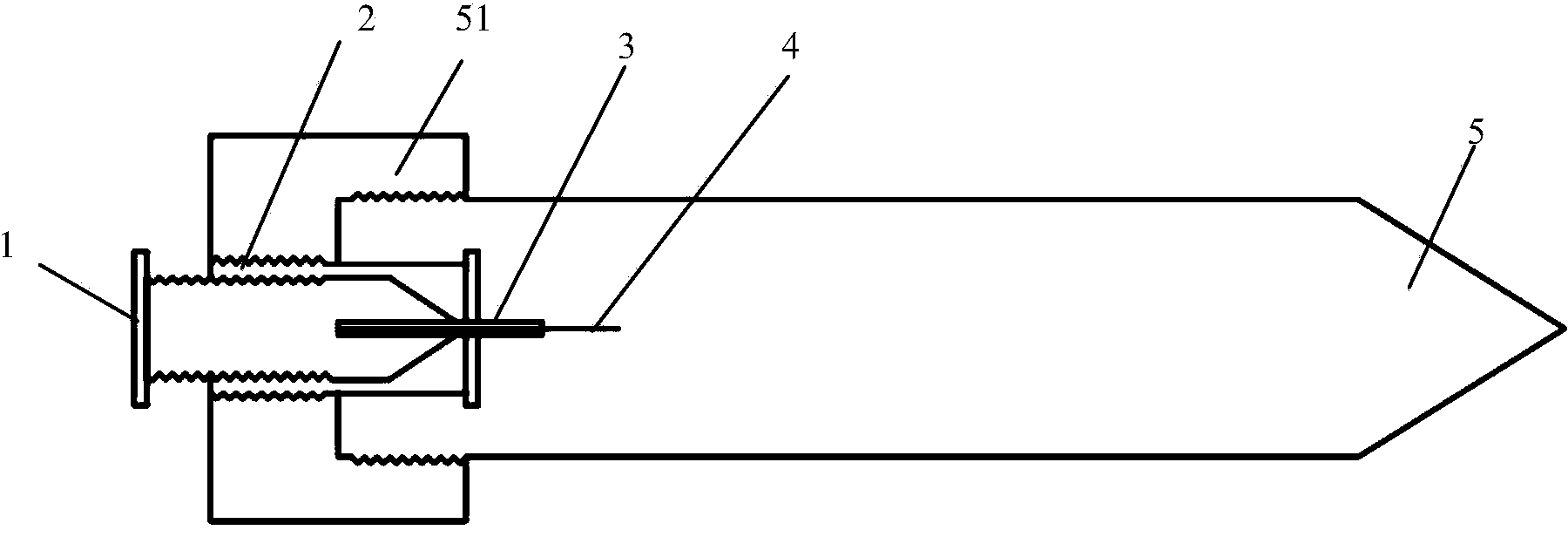

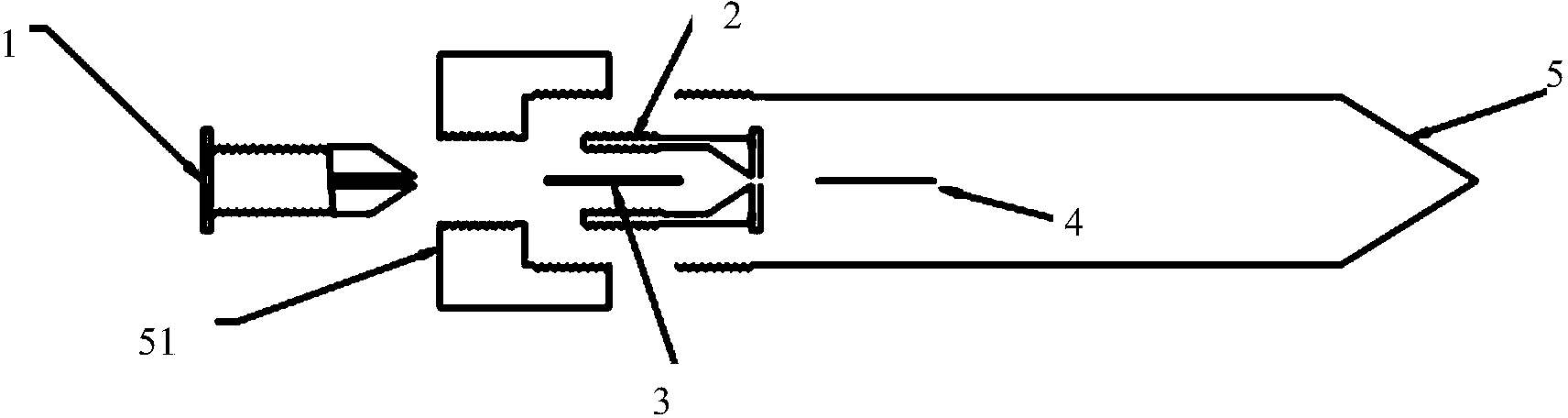

[0034] Example 1: Alkyl modified SiO 2 Preparation of Nano-filled Capillary Chromatography Microcolumns

[0035] a Alkyl modified SiO 2 Synthesis of nanofillers

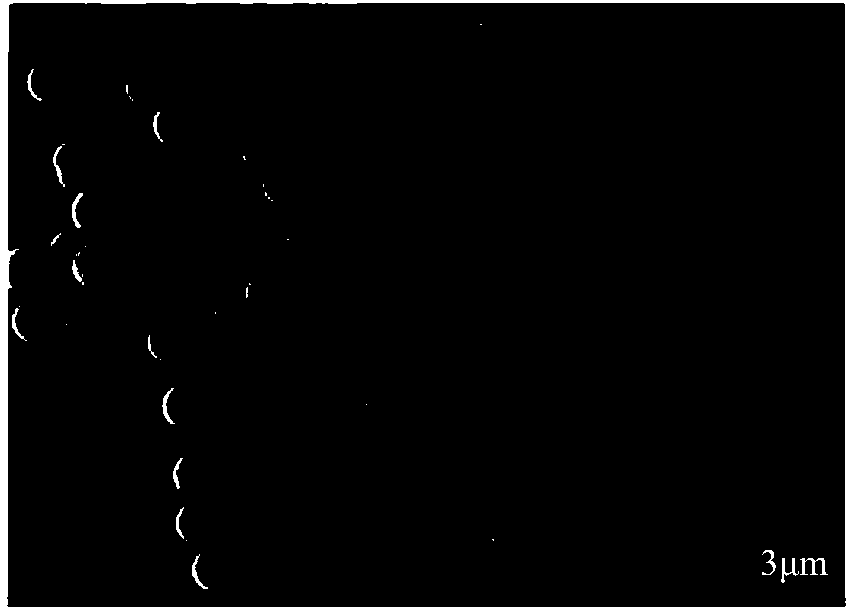

[0036] Mix absolute ethanol, water and ammonia water in a volume ratio of 47:9:14 into a round-bottomed flask, magnetically stir and mix evenly, and add the above 1 / 14 volume tetraethyl orthosilicate while stirring. Closed and stirred at a certain temperature for 6-10 hours; then add half volume of tetraethyl orthosilicate, absolute ethanol, water, etc. under stirring state, continue to react for 6-10 hours, age for 1-2 hours, centrifuge and wash for at least 3 times, washed with ethanol at least 3 times, dried at 110°C for 4-6 hours, and within 16 hours after cooling, the temperature was programmed from room temperature to 600-650°C in a muffle furnace. image 3 and 4 For the synthesized SiO 2 Scanning electron microscope (SEM) and transmission electron microscope (TEM) images of nano fillers show that the synt...

Embodiment 2

[0048] Example 2: SiO 2 Preparation of Au-S-C18 nano-packed column for capillary chromatography enrichment

[0049] a SiO 2 Preparation of Au-S-C18 Core-Shell Nanofillers

[0050] First, a certain amount of SiO prepared according to Example 1 2 Disperse the nanospheres in 10mL of 1:1 methanol and water solution, prepare 90mL of 0.03M SnCl 2 The solution was mixed with the above-mentioned nanoparticle dispersion, reacted for 45min under magnetic stirring, and dispersed in 4mL water after being washed by centrifugation for 8 times; secondly, 1.5mL1g / 100mL chloroauric acid was added to the 2 CO 3 100mL of water, react in dark for at least 24h to form aging solution. Add 1mL SiO to 50mL aging solution 2 sn 2+ For dispersion liquid, add hydroxylamine hydrochloride solution of appropriate concentration drop by drop under magnetic stirring until the reaction solution is bright blue, react for 8-10 hours, then age for 1 hour, wash with water at least 6 times, and then dry overn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com